Abstract

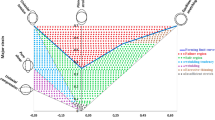

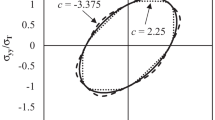

Sheet bulk metal forming is widely used for medium-thick metal plate due to its convenience in the manufacture of accurately finished 3D functional components. To obtain precise anisotropy and flow curve of metal plate is a prerequisite for correct simulation of sheet bulk metal forming processes. Inverse analysis of compression test was introduced here to evaluate the sensitivity of different flow curve models and geometric influence of compression test specimen. Besides, a methodology was proposed to compute plastic anisotropic coefficients of Hill quadratic yield criterion, which is based on the ratios of flow curves obtained by inverse analysis of compression tests using specimens cut in six directions on the medium-thick metal plate. The obtained flow curves and anisotropic coefficients were compared with those calculated from tensile tests. Flow curves based on inverse analysis of compression tests cover the curves of the tensile tests well, while the anisotropic coefficients are different, especially for the coefficient related to the RT45 direction. To estimate the effectiveness of the proposed method, the calculated material properties and those based on the traditional tensile tests were applied in a rim-hole process simulation. The simulation results based on the material properties from inverse analysis of compression tests accorded with the tested properties better.

Similar content being viewed by others

References

M. Merklein, J. Koch, T. Schneider, S. Opel, U. Vierzigmann, Int. J. Mater. Form. 3 (2010) 347–350.

Y. C. Jia, H. R. Guo, R. Li, H. L. Li, J. Iron Steel Res. Int. 19 (2012) No. 3, 52–55.

X. C. Zhuang, Z. Zhao, H. Y. Li, H. Xiang, Steel Res. Int. 84 (2013) 146–154.

X. D. Wang, M. Yao, L. Zhang, X. B. Zhang, S. H. Chen, J. Iron Steel Res. Int. 20 (2013) No. 1, 13–20.

D. Szeliga, J. Gawad, M. Pietrzyk, Comp. Meth. Appl. Mech. Eng. 195 (2006) 6778–6798.

M. Joun, J. G. Eom, M. C. Lee, Mech. Mater. 40 (2008) 586–593.

Z. L. Zhang, J. Odegird, O. P. Sovik, Comp. Mater. Sci. 20 (2001) 77–85.

E. E. Cabezas, D. J. Celentano, Finite Elem. Anal. Des. 40 (2004) 555–575.

M. Kamaya, M. Kawakubo, Mech. Mater. 43 (2011) 243–253.

E. Parteder, R. Bunten, J. Mater. Process. Technol. 74 (1998) 227–233.

R. Hill, J. Mech. Phy. Solids 38 (1990) 405–417.

H. Hoffmann, C. Vogl, CIRP Ann. -Manuf. Tech. 52 (2003) 217–220.

K. Pöhlandt, K. Lange, M. Zucko, Steel Res. 69 (1998) 170–174.

B. Carlsson, P. Huml, CIRP Ann.-Manuf. Technol. 45 (1996) 231–233.

M. Terano, K. Kitamura, T. Fukatsu, T. Mizuno, J. Solid Mech. Mater. Eng. 3 (2009) 256–266.

S. Dziallach, W. Bleck, M. Blumbach, T. Hallfeldt, Adv. Eng. Mater. 9 (2007) 987–994.

W. B. Morrison, Trans. ASM 59 (1966) 824–846.

P. Koc, B. Štok, Comp. Mater. Sci. 31 (2004) 155–168.

S. R. Kalidindi, A. Abusafieh, E. El-Danaf, Exp. Mech. 37 (1996) 210–215.

J. A. Nelder, R. Mead, The Computer Journal 7 (1965) 308–313.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (51105250); National Science and Technology Specific Projects of China (2011ZX04016-051)

Rights and permissions

About this article

Cite this article

Zhuang, Xc., Xiang, H., Wang, T. et al. Determination of flow curve and plastic anisotropy of medium-thick metal plate: experiments and inverse analysis. J. Iron Steel Res. Int. 22, 506–512 (2015). https://doi.org/10.1016/S1006-706X(15)30033-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(15)30033-9