Abstract

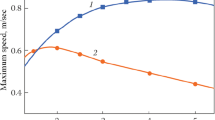

The electromagnetic field and flow analysis model were developed to simulate the electromagnetic field and the flow pattern in a vertical curved continuous slab caster with the in-roll type strand electromagnetic stirring. The transient electromagnetic field distribution and the induced electromagnetic force were numerically described. The effects of stirring current, stirring frequency, and different stirrer configurations on the electromagnetically driven flow field in the strand were investigated and the optimization of the stirring parameters was discussed by performing a relative comparison of numerical results. Results show that the in-roller type strand electromagnetic stirrer (S-EMS) pair generates the fluctuating magnetic fields, penetrating through the cast slab and periodically parallel shifting along the slab wide face with time evolution. The transient induced electromagnetic forces travels toward the magnetic flux shifting direction. Different stirring parameters (i. e. current and frequency) and stirrer configurations affect the stirring strength and the flow recirculation pattern in the strand, which arc closely related to metallurgical performances of the stirrers. There is an optimum frequency to obtain the maximum stirring. The present model provides a relatively theoretical insight into the in-roll type strand electromagnetic stirring system for best operating.

Similar content being viewed by others

References

J. H. Chen, S. Y. Lin, M. J. Lu, China Steel Tech. Rep. 23 (2010) 6–13.

S. Kittaka, Y. Maruki, T. Fukuokaya, T. Kanki, Nippon Steel Tech. Rep. 8 (2003) 70–74.

V. Lambert, J. M. Galpin, H. R. Hackl, N. P. Jacobson, Iron Steel Technol. 5 (2008) No. 7, 71–79.

B. G. Thomas, R. Chaudhary, in: 6th Int. Conf. on Electromagnetic Processing of Materials EPM 2009, Forschungszentrum Dresden-Rossendrof, Dresden, Germany, 2009, pp. 9–14.

H. P. Liu, M. G. Xu, S. T Qiu, H. Zhang, Metall Mater Trans. B 43 (2012) 1657–1675.

M. Barna, M. Javurek, J. Reiter, M. Lechner, BHM 154. Jg. 11 (2009) 518–522.

A. F. Kolesnichenko, A. A. Kolesnichenko, V. V. Buryak, ISIJ Int. 44 (2004) 342–349.

H. Yu, M. Y. Zhu, IEEE Trans. Magn. 46 (2010) 82–86.

M. Javurek, M. Barna, P. Gitler, K. Rockenschaub, M. Lechner, Steel Res. Int. 79 (2008) 617–625.

M. Dubke, K. H. Tacke, K. H. Spitzer, K. Schwerdtfeger, Metall. Trans. B 19 (1986) 581–593.

M. Dubke, K. H. Tacke, K. H. Spitzer, K. Schwerdtfeger, Metall. Trans. B 19 (1986) 595–602.

N. El-Kaddah, T. T. Natarajan, in: Second Int. Conf. on CFD in the Minerals and Process Industries, CSIRO, Melbourne, Australia, 1999, pp. 339–344.

Y. C. Yin, J. C. Li, B. F. Wang, Foundry Technology 33 (2012) 319–320.

J. C. Li, Y. C. Yin, B. F. Wang, Special Casting & Nonferrous Alloys 33 (2013) 318–322.

L. B. Trindade, A. C. F. Vilela, A. F. F. Filho, M. T. M. B. Vilhena, R. B. Soares, IEEE Trans. Magn. 38 (2002) 3658–3660.

F. C. Chang, J. R. Hull, L. Beitelman, Metall. Mater. Trans. B 35 (2004) 1129–1137.

T. H. Shih, W. W. Liou, A. Shabbir, Z. Yang, J. Zhu, Comput. Fluids 24 (1995) 227–238.

ANSYS Inc., ANSYS FLUENT Theory Guide 14. 0, Canonsburg, PA, USA, 2011.

H. P. Liu, Numerical Simulation of Transport Characteristics during the Solidification Process in a Continuous Slab Caster Based on the Continuum Model, Central Iron and Steel Research Institute, Beijing, 2002.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gong, J., Liu, Hp., Wang, Xh. et al. Numerical simulation of electromagnetic field and flow pattern in a continuous slab caster with in-roll type strand electromagnetic stirring. J. Iron Steel Res. Int. 22, 414–422 (2015). https://doi.org/10.1016/S1006-706X(15)30021-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(15)30021-2