Abstract

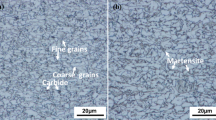

Based on pre-punching to hot rolled martensitic and bainitic dual phase steels with similar elongation and work hardening index (n), as well as similar thickness and hole expansion test using taper die, analysis of the hole expansion rate indicated significant difference in their flanging performance. The results indicated that mechanical property was not the only major factor that influenced flanging. Further analysis of the hole border microstructure, work hardening condition, and fracture property showed that the fracture property of sheets was the major factor that influenced flanging performance.

Similar content being viewed by others

References

Y. P. Guan, T. Zhang, J. Zhao, Journal of Yanshan University 26 (2002) 216–223.

Y. M. Huang, K. H. Chien, J. Mater. Process. Technol. 117 (2001) 43–51.

X. Fang, Z. Fan, B. Ralph, P. Evans, R. Underhill, J. Mater. Sci. 38 (2003) 3877–3882.

R. J. Comstock, D. K. Scherrer, R. D. Adamczyk, J. Mater. Eng. Perform. 15 (2006) 675–683.

P. Papanikos, S. A. Meguid, Int. J. Mech. Sci. 40 (1998) 1019–1028.

R. Narayanasamy, C. Sathiya Narayanan, P. Padmanabhan, T. Venugopalan, Int. J. Adv. Manuf. Technol. 47 (2010) 365–380.

M. Takahashi, Nippon Steel Tech. Rep. 88 (2003) 2–7.

N. Asnafi, J. Mater. Process. Technol. 96 (1999) 198–214.

Y. Umehara, J. Mater. Process. Technol. 22 (1990) 239–256.

T. N. Chakherlou, J. Vogwell, Eng. Fail. Anal. 10 (2003) 13–24.

T. Kuwabara, K. Hashimoto, E. Iizuka, J. W. Yoon, J. Mater. Process. Technol. 211 (2011) 475–481.

L. Xu, F. Barlat, M. G. Lee, Scripta Mater. 66 (2012) 1012–1017.

T. Cohen, R. Masri, D. Durban, Int. J. Solids Struct. 46 (2009) 3643–3650.

J. H. Kim, M. G. Lee, D. Kim, D. K. Matlock, R. H. Wagoner, Mater. Sci. Eng. A 527 (2010) 7353–7363.

K. I. Mori, Y. Abe, Y. Suzui, J. Mater. Process. Technol. 210 (2010) 653–659.

D. I. Hyun, S. M. Oak, S. S. Kang, Y. H. Moon, J. Mater. Process. Technol. 130–131 (2002) 9–13.

G. H. Strijbos, R. Boesenkool, in: Proceedings of 19th IDDRG Biennial Congress, Eger, 1999, pp. 459–466.

L. Xu, L. Chen, B. C. De Cooman, D. Steglich, F. Barlat, Int. J. Mater. Form. 3 (2010) Suppl. 1, 247–250.

S. H. Dong, Y. M. Lü, Z. H. Chen, Chin. J. Mech. Eng. 38 (2002) 47–50.

T. Mega, K. Kasegawa, H. Kawabe, JFE Tech. Rep. 4 (2004) 38–43.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (51275003)

Rights and permissions

About this article

Cite this article

Qian, Jq., Yue, Y. Factors Influencing Dual Phase Steel Flanging Limit Punching. J. Iron Steel Res. Int. 21, 1124–1128 (2014). https://doi.org/10.1016/S1006-706X(14)60193-X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(14)60193-X