Abstract

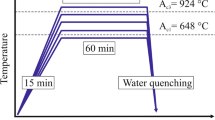

2k factorial design is employed to find the mathematical relation between the carbon content and intercritical annealing temperature (IAT) in order to predict the responses namely martensite volume fraction (MVF), microhardness (H), yield strength (YS), ultimate tensile strength (UTS), total elongation (TEL), yield ratio (YR) and Charpy impact energy (CIE) in dual phase (DP) steels. Steels containing diferent carbon contents (0. 085% C and 0.380% C) had been chosen for this purpose. The main advantages of factorial design are its easy implementation and the effective computation compared with the other optimization techniques, which were employed for predicting mentioned responses in the literature. To verify the proposed approach based on factorial design, experiments for verification were performed. The results of the verification experiments and the mathematical models are in accordance with each other and the literature.

Similar content being viewed by others

References

F. Hayat, H. Uzun, J. Iron Steel Res. Int. 18 (2011) No. 8, 65–72.

H. Aydin, Z. H. Kazdal, K. Ceylan, J. IronSteel Res. Int. 17 (2010) No. 4, 73–78.

A. A. Sayed, S. Kheirandish, Mater. Sci. Eng. A 532 (2012) 21–25.

S. K. Paul, Comput. Mater. Sci. 56 (2012) 34–42.

N. Peranio, Y. J. Li, F. Roters, D. Raabe, Mater. Sci. Eng. A 527 (2010) 4161–4168.

T. D. Islahani, A. Shalyei, H. Sharili, Fatigue Fract. Eng. Mater. Struct. 32 (2009) 141–147.

V. Colla, M. Desanctis, A. Dimatteo, G. Lovicu, R. Valentin! Metall. Mater. Trans. 42 (2011) 2781–2793.

Y. Prawoto, M. Fanone, S. Shahedi, M. S. Ismail, W. B. Wan Nik, Comput. Mater. Sci. 54 (2012) 48–55.

S. J. Kim, Y. G. Cho, C. S. Oh, D. E. Kim, M. B. Moon, H. N. Han, Mater. Des. 30 (2009) 1251–1257.

M. Asadi, G. Frommeyer, A. Aghajani, I. Timokhina, H. Palkowski, Metall. Mater. Trans. 43 (2012) 1244–1258.

J. Luo, W. Shi, Q. Huang, L. Li, J. Iron Steel Res. Int. 17 (2010) No. 1, 54–58.

H. Liu, F. Li, R. Liu, L. Li, Suri. Coat. Technol. 205 (2011) 3535–3539

N. Farabi. D. L. Chen, Y. Zhou, J. Alloys Compds. 509 (2011) 982–989

D. S. Rao, H. S. Hebbar, M. Komaraiah, U. N. Kempaiah, Mater. Manul. Process. 23 (2008) 295–302.

D. S. Rao, H. S. Hebbar, M. Komaraiah, Mater. Manul. Process. 22 (2007) 825–829.

U. Reisgen, M. Schleser, O. Mokrov, E. Ahmed, Opt. Laser Technol. 44 (2012) 255–262.

M. Hazratinezhad, N. B. Mostala, A. R. Sulizadeh, M. J. Torkamany, Mater. Des. 33 (2012) 83–87.

N. Farabi. D. L. Chen, J. Li, Y. Zhou, S. J. Dong, Mater. Sci. Eng. A 527 (2010) 1215–1222.

X. Liao, X. Wang, Z. Guo, M. Wang, Y. Wu, Y. Rong, Mater. Charact. 61 (2010) 341–346.

F. Hayat, J. Iron Steel Res. Int. 18 (2011) No. 9, 70–78.

V. H. B. Hernandez, S. K. Panda, M. L. Kuntz, Y. Zhou, Mater. Lett. 64 (2010) 207–210.

L. R. Bhagavathi, G. P. Chaudhari, S. K. Nath, Mater. Des. 32 (2011) 433–440.

P. P. Sarkar, P. Kumar, M. K. Manna, P. C. Chakraborti, Mater. Lett. 59 (2005) 2488–2491.

I. J. Park, S. T. Kim, I. S. Lee, Y. S. Park, M. B. Moon, Mater. Trans. 50 (2009) 1440–1447.

O. Kelestemur, S. Yildiz. Constr. Build. Mater. 23 (2009) 7884

P. K. Ray, R. I. Ganguly, A. K. Panda, Mater. Sci. Eng. A 346 (2003) 122–131.

D. C. Montgomery, Design andAnalysis of Experiments, Fifth ed., John Wiley & Sons, Inc., New York, 2001.

F. G. Giesbrecht, M. L. Gumpertz, Planning, Construction, and Statistical Analysis of Comparative Experiments, John Wiley & Sons, Inc., New Jersey, 2004.

R. L. Mason, R. F. Gunst, J. L. Hess, Statistical Design and Analysis of Experiments, Second ed., John Wiley & Sons, Inc., New Jersey, 2003.

E. D. Castillo, Process Optimization—A Statistical Approach, Springer, New York, 2007.

A. P. Modi, Tribol. Int 40 (2007) 490–497.

P. Movahed, S. Kolahgar, S. P. H. Marashi, M. Pouranvari, N. Parvin, Mater. Sci. Eng. A 518 (2009) 1–6.

F. G. Caballero, A. G. Junceda, C. Capdevila, C. G. Andres, Mater. Trans. 47 (2006) 2269–2276.

A. Bag, K. K. Ray, E. S. Dwarakadasa, Metall. Mater. Trans. 30 (1999) 1193–1202.

M. Pouranvari, MJoM 16 (2010) 187–194.

N. Fonstein, M. Kapustin, N. Pottore, I. Gupta, O. Yakubosky, Phys. Met. Metallog. 104 (2007) 315–323.

O. Henry, K. C. Monde, Mater. Res. 11 (2008) 97–101.

M. A. Maleque, Y. M. Poon, H. H. Masjuki. J. Mater. Process. Technol. 153–154 (2004) 482–487.

G. R. Speich, in; Fundamentalsof Dual-phaseSteels: Proceedings of a Symposium, The Metall. Soc., Ann Arbor, 1981, pp. 1–45.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Toktas, G., Toktas, A. & Karaoglan, A.D. Mathematical Modeling of Carbon Content and Intercritical Annealing Temperature in DP Steels by Factorial Design Method. J. Iron Steel Res. Int. 21, 715–722 (2014). https://doi.org/10.1016/S1006-706X(14)60111-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(14)60111-4