Abstract

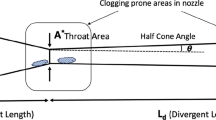

The impeler blade structure for gas injection refining under mechanical stirring has been explored by water model experiments. A sloped swept-back blade impeler is proposed for the purpose. The central part of the impeler is diskG or plate-shaped, and the blades are fited to the side of the disk or plate. In addition, a disk is put on the top side of the impeler blades. The impeler can strengthen the radial and downward flow between the blades and weaken the swirl flow in the zone above the impeler. These efects on flow phenomena are favorable for disintegration and wide dispersion of bubbles which are injected from a nozzle atached to the center of the underside of the impeler. In addition, the sloped swept-back impeler requires less power consumption. The impeler shaft should be placed away from the vessel center so as to disperse the injected bubbles widely in the bath under mechanical stiring even with unidirectional impeler rotation and without instaling bafles. The number of gas holes in the nozzle and the direction of gas injection have a litle effect on the bubble disintegration and dispersion in the bath. Highly eficient gas injection refining can be established under the conditions of proper impeler size, larger nozzle immersion depth, larger eccentricity and rotation speed of the impeler. The sloped swept-back blade impeler can decrease the power consumption and yet improve the bubble disintegration and wide dispersion in the bath.

Similar content being viewed by others

References

K. Masuda, Y. Morishima, in: Progress in Chemical Engineering 16 (Bubble Drop Dispersion Engineering), The Society of Chemical Engineers, Tokyo, 1982, pp. 125.

A. H. Castilejos, J. K. Brimacombe, Metal. Mater. Trans. B 20 (1989) 595–601.

G. Szekely, Metal. Mater. Trans. B 7 (1976) 259–270.

A. K. Fukuoka, Method for Refining Molten Metal and Manufacturing Ingot or Casting of Light Metal, Japan, H7-122106, 1995.

Y. Q. Weng, Ultra-fine Grained Steels, Metalurgical Industry Press, Beijing, 2007.

Z. Wang, Vacuum (1999) No. 4, 37–41.

Y. Liu, M. Sano, T. A. Zhang, Q. Wang, J. C. He, ISIJ Int. 49 (2009) 17–23.

Y. Liu, T. A. Zhang, Z. H. Dou, G. Z. Lü, P. Shao, L. L. Ye, J. C. He, J. Iron Steel Res. Int. 17 (2010) S2, 1–7.

Y. Liu, T. A. Zhang, M. Sano, Q. Wang, X. D. Ren, J. C. He, Trans. Nonferrous Met. Soc. China 21 (2011) 1896–1904.

Y. Liu, T. A. Zhang, M. Sano, Q. Wang, J. C. He, J. Iron Steel Res. Int. 18 (2011) S2, 166–171.

Y. Liu, Z. M. Zhang, J. N. Zhang, S. Masamichi, J. Zhang, J. Iron Steel Res. Int. 20 (2013) No. 12, 1–6.

T. Nomura, M. Iguchi, Tetsu-to-Hagane 88 (2002) 1–7.

P. H. Calderbank, Trans. Inst. Chem. Eng. 36 (1918) 443–463.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (50974035, 51074047); National High Technology Research and Development Program (863 Program) of China (2010AA03A405, 2012AA062303); Innovation Team Project of Provincial Science and Technology of Liaoning Province of China (LT2010034)

Rights and permissions

About this article

Cite this article

Liu, Y., Zhang, Zm., Masamichi, S. et al. Improvement of Impeler Blade Structure for Gas Injection Refining under Mechanical Stirring. J. Iron Steel Res. Int. 21, 135–143 (2014). https://doi.org/10.1016/S1006-706X(14)60022-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(14)60022-4