Abstract

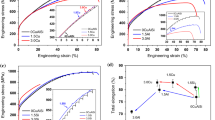

The influence of carbon content on the stacking fault energy (SFE) of Fe-20Mn-3Cu twinning-induced plasticity (TWIP) steel was investigated by means of X-ray diffraction peak-shift method and thermodynamic modeling. The experimental result indicated that the stacking fault probability decreases with increasing carbon addition, the SFE increases linearly when the carbon content in mass percent is between 0. 23% and 1. 41%. The thermodynamic calculation results showed that the SFE varied from 22. 40 to 29. 64 mJ • m−2 when the carbon content in mass percent changes from 0. 23% to 1. 41%. The XRD analysis revealed that all steels were fully austenitic before and after deformation, which suggested that TWIP effect is the predominant mechanism during the tensile deformation process of Fe-20Mn-3Cu-XC steels.

Similar content being viewed by others

References

O. Grässel, L. Krüger, G. Frommeyer L. W. Meyer, Int. J. Plast. 16 (2000) 1391–1409.

G. Frommeyer, U. Brüx, P. Neumann, ISIJ Int. 43 (2003) 438–446.

S. Vercammen, B. Blanpain, B. C. De Cooman, P. Wollants, Acta Mater. 52 (2004) 2005–2012.

J. Kim, S. J. Lee, B. C. De Cooman, Scripta Mater. 65 (2011) 363–366.

B. W. Oh, S. J. Cho, Y. G. Kim, Y. P. Kim, W. S. Kim, S. H. Hong, Mater. Sci. Eng. A 197 (1995) 147–156.

L. Remy, A. Pineau, Mater. Sci. Eng. 28 (1977) 99–107.

Y. J. Dai, D. Tang, Z. L. Mi, J. C. Lü, J. Iron Steel Res. Int. 17 (2010) No. 9, 53–59.

I. Gutierrez-Urrutia, D. Raabe, Acta Mater. 59 (2011) 6449–6462.

M. Koyama, E. Akiyama, K. Tsuzaki, Corros. Sci. 54 (2012) 1–4.

R. E. Schramm, R. P. Reed, Metall. Mater. Trans. A 6 (1975) 1345–1351.

P.J. Brofman, G. S. Ariseli, Metall. Mater. Trans. A 9 (1978) 879–880.

Y. N. Petrov, Scripta Metall. Mater. 29 (1993) 1471–1476.

A. Abbasi, A. Dick, T. Hickel, J. Neugebauer, Acta Mater. 59 (2011) 3041–3048.

Y. H. Rong, G. He, Z. H. Guo, S. P. Chen, T. Y. Hsu, J. Mater. Sci. Technol. 18 (2002) 459–461.

S. Curtze, V. T. Kuokkala, Acta Mater. 58 (2010) 5129–5141.

S. Curtze, V. T. Kuokkala, A. Oikari, J. Talonen, H. Hanninen, Acta Mater. 59 (2011) 1068–1076.

G. B. Olson, M. Cohen, Metall. Trans. A 7 (1976) 1897–1904.

B. E. Warren, X-Ray Diffraction, Addison-Wesley, Massachusett, 1969.

J. P. Hirth, Metall. Mater. Trans. B 1 (1970) 2367–2374.

A. Dumay, J. P. Chateau, S. Allain, S. Migot, O. Bouaziz, Mater. Sci. Eng. A 483–484 (2008) 184–187.

S. Allain, J. P. Chateau, O. Bouaziz, S. Migot, N. Guelton, Mater. Sci. Eng. A 387–389 (2004) 158–162.

M. Hillert, M. Jarl, Calphad 2 (1978) 227–238.

L. Lin, T. Y. Hsu, Calphad 21 (1997) 443–448.

S. Cotes, M. Sade, A. Fernandez Guillermet, Metall. Mater. Trans. A 26 (1995) 1957–1969.

Y. J. Dai, Z. L. Mi, D. Tang, J. C. Lü, J. Iron Steel Res. 23 (2011) No. 4, 32–36.

W. Huang, Calphad 13 (1989) 231–242.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by Industry-University Cooperation Major Program of Science and Technology Department of Fujian Province of China (2011H6012); Key Program of Science and Technology Department of Fujian Province of China (2011H0001)

Rights and permissions

About this article

Cite this article

Peng, X., Zhu, Dy., Hu, Zm. et al. Effect of Carbon Content on Stacking Fault Energy of Fe-20Mn-3Cu TWIP Steel. J. Iron Steel Res. Int. 21, 116–120 (2014). https://doi.org/10.1016/S1006-706X(14)60018-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(14)60018-2