Abstract

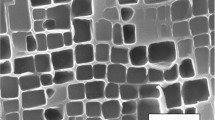

Samples of DD3 single crystal superalloy with different dimensions were cast in the directionally solidified furnace with high temperature gradient. The effect of cast dimension on the rotary bending high cycle fatigue (HCF) properties of the alloy was investigated at 800 °C in ambient atmosphere. SEM was used to examine the fracture surface and fracture mechanism of the alloy. The results show that the rotary bending HCF properties of the alloy decreases with increasing cast dimension. The cast dimension has little effect on the HCF fracture mechanism of the alloy. The HCF fracture mechanism of the alloy with different cast dimensions is all quasi-cleavage fracture. The fatigue cracks initiated on the surface or near the surface of the specimens. The crack would propagate along {111} octahedral slip planes. Typical fatigue arc and striation formed on fatigue crack steady propagation. The degeneration of HCF properties is due to the increase of dendrite arm spacing and size of γ’ phase particles and maximal microporosity.

Similar content being viewed by others

References

Wright P K, Jain M, Cameron D. High Cycle Fatigue in a Single Crystal Superalloy: Time Dependence at Elevated Temperature [C]. Green K A, Pollok T M, Harda H, et al. Superalloys 2004. Pennsylvania: TMS, 2004: 657.

Lukas P, Kunz L, Svoboda M. High Cycle Fatigue of Superalloy Single Crystals at High Mean Stress [J]. Materials Science and Engineering, 2004, 387–388A: 505.

Lamm M, Singer R F. The effect of Casting Conditions on the High-Cycle Fatigue Properties of the Single-Crystal Nickel-Base Superalloy PWA1483 [J]. Metallurgical and Materials Transactions, 2007, 38A(6): 1177.

Wilson BC, Cutler E R, Fuchs G E. effect of Solidification Parameters on the Microstructures and Properties of CMSX-10 [J]. Materials Science and Engineering, 2008, 479A(1): 356.

Zhang W M, Du W, Fu H Z. effect of Solidification Condition on Microstructure and Mechanical Properties of Single Crystal Superalloy [J]. Journal of Material Science and Technology, 2001, 17(1): 89.

Liu C B, Shen J, Zhang J, et al. effect of Withdrawal Rates on Microstructure and Creep Strength of a Single Crystal Superalloy Processed by LMC [J]. Journal of Material Science and Technology, 2010, 26(4): 3.

SHI Zhen-xue, HAN Mei, LIU Shi-zhong, etal. Effect of Sample Sizeon Microstructureof a Single Crystal Superalloy [J]. Journal of Iron and Steel Research, 2012, 24(4): 28 (in Chinese).

ASTM, Annual book of ASTM standard, ASTM standard E606, Vol. 03.01, ASTM [M]. Philadelphia, PA, 1996.

Shi Z X, Li J R, Liu S Z, et al. High Cycle Fatigue Behavior of the Second Generation Single Crystal Superalloy DD6 [J]. Transac tion Nonferrous Metal Society of China, 2011, 21(5): 998.

Chu Z K, Yu J J, Sun X F, et al. High Cycle Fatigue behavior of a Directionally Solidified Ni-Base Superalloy DZ [J]. Materials Science and Engineering, 2008, 496A(1): 951.

Müller S, Rösler J, Sommer C, et al. The Influence of Load Ratio, Temperature, Orientation and Hold Time on Fatigue Crack Growth of CMSX-4 [C]. Pollock T M, Kissinger R D, Bowman R R, et al. Superalloys 2000. Warrendale: TMS, 2000: 347.

Liu Y, Yu J J, Xu Y, et al. High Cycle Fatigue Behavior of a Single Crystal Superalloy at Elevated Temperatures [J]. Materials Science and Engineering, 2007, 454–455A: 357.

Jackon J J, Donachie M J, Henricks R J. effect of Amount (Vf) of Fine γ’ Particle on Creep Property for DS MarM200 + Hf Superalloy [J]. Metallurgical Transaction, 1977, 8A(10): 1.

Hino T, Kobayashi T, Koizumi Y. Development of a New Single Crystal Superalloy for Industrial Gas Turbines [C]. Pollock T M, Kissinger R D, Bowman R R, et al. Superalloys 2000. Warrendale: TMS, 2000: 729.

Zhang J X, Wang J C, Harada H. The effect of Lattice Misfit on the Dislocation Motion in Superal loy During High Temperature Low Stress Creep [J]. Acta Materialia, 2005, 53(17): 4623.

Liu L, Huang T W, Zhang J, et al. Microstructure and Stress Rupture Properties of Single Crystal Superalloy CMSX-2 Under High Thermal Gradient Directional Solidification [J]. Materials Letters, 2007, 61(1): 227.

ZHAO Nai-ren, JIN Tao, SUN Xiao-feng, et al. effects of Withdrawal Rate on Microstructure and Mechanical Property of Single Crystal Superalloy SRR99 [J]. Chinese Journal of Materials Research, 2008, 22(1): 46 (in Chinese

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shi, Zx., Han, M., Liu, Sz. et al. Influence of Cast Dimension on Rotary Bending High Cycle Fatigue Properties of Single Crystal Superalloy. J. Iron Steel Res. Int. 20, 98–102 (2013). https://doi.org/10.1016/S1006-706X(13)60222-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(13)60222-8