Abstract

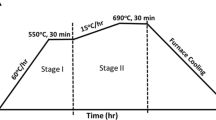

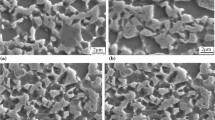

Low-carbon Cr-Mo micro-alloyed deep drawing dual-phase steels were designed in laboratory. As the microstructure and texture evolution in hot-rolled strips and annealed sheets were investigated using SEM, TEM and XRD technologies, the attribution of solute Mo and MoC particles to DP sheets’ drawing capacity was investigated. The precipitation thermodynamics were also calculated by Thermo-calc software. Results show that the precipitates in hot-rolled strips mainly are MoC, AlN and MnS, and with the increase of Mo-addition, finer and denser MoC particles precipitated in matrix and along grain boundaries of ferrite more easily. Weak textures are shown in the hot-rolled strips, and {112}<110> and {223}<110> components tend to be stable in subsequent cold rolling process. During annealing, on one hand, the development of <111> //ND texture is suppressed because finer MoC particles prevent the grain boundary migration. On the other hand, unfavorable texture {001}<110> significantly reduces with Mo increasing, which is attributed to that part of solution C in matrix has been fixed during recrystallization. In addition, the addition of Mo can enhance hardenability strongly and MoC easily re-dissolve at high temperature, which is favor to form martensite in dual-phase steel.

Similar content being viewed by others

References

Demir B, Erdogan M. The Hardenability of Austenite With Diferent Aloy Content and Dispersion in Dual-Phase Steels [J]. Journal of Materials Processing Technology, 2008, 208 (1): 75.

Hsun H U. Studies on the Development of High-Strength Dual-Phase Steel Sheets With High rm Values [J]. Metalurgical and Materials Transactions, 1982, 13A(7): 125.

Han S H, Choi S H, Choi J K, et al. Effect of Hot-Roling Processing on Texture and r-Value of Annealed Dual-Phase Steels [J]. Materials Science and Engineering, 2010, 527A (7): 1686.

Ghosh P, Ray R K, Ghosh C, et al. Comparative Study of Precipitation Behavior and Texture Formation in Continuously Annealed Ti and Ti + Nb Added Interstitial-Free High-Strength Steels [J]. Scripta Materialia, 2008, 58(11): 939.

Vanderschueren D, Yoshinaga N, Koyama K. Recrystalisation of TiGIF Steel Investigated With Electron BackScatering Pattern (EBSP) [J]. ISIJ International, 1996, 36(8): 1046.

Kang J Y, Lee H C, Han S H. Effect of Al and Mo on the Textures and Microstructures of Dual Phase Steels [J]. Materials Science and Engineering, 2011, 530A(15): 183.

Yuan Shao-qiang, Liang Guo-li, Zhang Xiao-juan. Interaction Between Elements Nb and Mo During Precipitation in Microal-loyed Austenite [J]. Journal of Iron and Steel Research, International, 2010, 17(9): 60.

Jonas J J. Efects of Shear Band Formation on Texture Development in Warm-Roled IF Steel [J]. Journal of Materials Processing Technology, 2001, 117(3): 293.

Hutchinson W B. Development and Control of Annealing Textures in Low-Carbon Steels [J]. International Materials Reviews, 1981, 29(1): 25.

Bandyopadhyay D, Haldar B, Sharma R C, et al. The Ti-Mo-C (Titanium-Molybdenum-Carbon) System [J]. Journal of Phase Equilibria, 1999, 20(3): 332.

Erdema G, Taptik Y. Effect of Hot Roling Conditions to Produce Deep Drawing Quality Steels for Continuous Annealing Process [J]. Journal of Materials Processing Technology, 2005, 170(1): 17.

Ray R K, Jonas J J, Butron M P, et al. Transformation Textures in Steels [J]. ISIJ International, 1994, 34(12): 927.

Inagaki H. Fundamental Aspect of Texture Formation in Low Carbon Steel [J]. ISIJ International, 1994, 34(4): 313.

Ruiz-Aparicio L J, Garcia C I, Deardo A J. Development of 111 Transformation Texture in InterstitialFree Steels [J]. Metalurgical and Materials Transaction, 2001, 32A(9): 2326.

Ray R K, Jonas J J, Hook R E. Cold Roling and Annealing Textures in Low Carbon and Extra Low Carbon Steel [J]. International Materials Reviews, 1994, 39(4): 129.

Subramanian S, Prikryl M, Gaulin B D, et al. Effect of Precipitate Size and Dispersion on Lank ford Values of Titanium Stabilized Interstitial-Free Steels [J]. ISIJ International, 1994, 34(1): 61.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (50904006); The Fundamental Research Funds for the Central Universities of China (FRT-TP-10-001A)

Rights and permissions

About this article

Cite this article

Wang, Zg., Zhao, Am., Zhao, Zz. et al. Precipitation Behavior and Textural Evolution of Cold-Rolled High Strength Deep Drawing Dual-Phase Steels. J. Iron Steel Res. Int. 20, 61–68 (2013). https://doi.org/10.1016/S1006-706X(13)60217-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(13)60217-4