Abstract

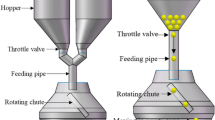

For the bell-less top blast furnace, when particles move along the chute, the particles’ motion direction and the frictional force acting on them will change due to the chute rotation, which consequently influences the velocity at the tip of chute, changes the burden flow width and impact point, and finally affects the stock profile and gas flow distribution. So the influence of chute rotation needs to be considered when calculating the burden trajectory with a mathematical model. The mathematical model was established to analyze the influence of Coriolis force on particle velocity at chute tip as well as height and width of burden flow in chute, and to summarize the effect of Coriolis force on burden distribution, thereby making the calculation result more accurate.

Similar content being viewed by others

Abbreviations

- F C :

-

Coriolis force, N

- F T :

-

Centrifugal force, N

- F N :

-

Supporting force, N

- F f :

-

Frictional force, N

- G:

-

Gravity force, N

- g:

-

Gravitational acceleration, m/s2

- H ch :

-

Chute torque length, m

- h db :

-

Height of burden flow in chute without chute rotating, m

- h rb :

-

Height of burden flow in chute with chute rotating, m

- h b :

-

Width of burden flow when it is out of chute, m

- l:

-

Distance of particle position to BF center, m

- L:

-

Length of chute, m

- L 0 :

-

Effective length of chute, m

- L m :

-

Length of particle moved in chute, m

- m:

-

Mass of a particle, kg

- N:

-

Normal pressure force, N

- R:

-

Radius of chute, m

- t:

-

Moving time, s

- v:

-

Velocity of particle, m/s

- x,y,z:

-

Distance of particles moved in X,Y, and Z axis, m

- α:

-

Chute inclinational angle, (°)

- ω:

-

Angular velocity of chute, rad/s

- θ:

-

Moved angle of burden along chute, (°)

- η:

-

Coefficient of friction

- φ:

-

Field angle of burden width when falling to chute, (°)

References

Ichida M, Nishihara K, Tamura K, et al. Influence of Ore/coke Distribution on Descending and Melting Behavior of Burden in Blast Furnace [J]. ISIJ International, 1991, 31(5): 505.

Pandey B D, Yadav U S. Blast Furnace Performance as Influenced by Burden Distribution [J]. Ironmaking and Steelmaking, 1999, 26(3): 187.

Anders Persson. How Do We Understand the Coriolis Force? [J]. Bulletin of the American Meteorological Society, 1998, 79(7): 1374.

Hattori M, Lino B, Shimomura A, et al. Development of Burden Distribution Simulation Model for Bell-Less Top in a Large Blast Furnace and Its Application [J]. ISIJ International, 1993, 33(10): 1070.

ZHU Qing-tian, CHENG Shu-sen. Mathematical Model of Burden Trajectory in a Blast Furnace [J]. Journal of University of Science and Technology Beijing, 2007, 29(9): 932 (in Chinese).

YU Yao-wei, BAI Chen-guang, LIANG Dong, et al. A Mathematical Model for Bell-Less Top Charging [J]. Iron and Steel, 2008, 43(11): 26 (in Chinese).

LIU Yun-cai. The Method of Burden Blast Furnace [M]. 3rd ed. Beijing: Metallurgical Industry Press, 2005 (in Chinese).

DU Peng-yu, CHENG Shu-sen, TENG Zhao-jie. Measurement of Charging Trajectory in Bell-Less Top Burden of Blast Furnace and 3-D Image Reconstruction [J]. Metallurgical Industry Automation, 2009, 33(6): 1 (in Chinese).

Nag S, Koranne V M. Development of Material Trajectory Simulation Model for Blast Furnace Compact Bell-less Top [J]. Iron-making and steelmaking, 2009, 36(5): 371.

Hiroshi Mio, Satoshi Komatsuki, Masatoshi Akashi, et al. Effect of Chute Angle on Charging Behavior of Sintered Ore Particles at Bell-Less Type Charging System of Blast Furnace by Discrete Element Method [J]. ISIJ International, 2009, 49(4): 479.

DU Peng-yu, CHENG Shu-sen, HU Zu-rui, et al. Mathematical Model of Burden Width in a Bell-less Top Blast Furnace and Modeling Experimental Research [J]. Iron and Steel, 2010, 45(1): 14 (in Chinese).

DU peng-yu, CHENG Shu-sen, BAI Yan-ming, et al. Suggestion the Ring-Number Divided With Burden Flow Width for a Bell-less Top Blast Furnace [J]. Ironmaking, 2010, 29(1): 37 (in Chinese).

Hiroshi Mio, Satoshi Komatsuki, Masatoshi Akashi, et al. Effect of Chute Angle on Charging Behavior of Sintered Ore Particles at Bell-less Type Charging System of Blast Furnace by Discrete Element Method [J]. ISIJ International, 2009, 49(4): 479.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (60872147)

Rights and permissions

About this article

Cite this article

Teng, Zj., Cheng, Ss., Zhao, Gl. et al. Effect of Chute Rotation on Particles Movement for Bell-less Top Blast Furnace. J. Iron Steel Res. Int. 20, 33–39 (2013). https://doi.org/10.1016/S1006-706X(13)60213-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(13)60213-7