Abstract

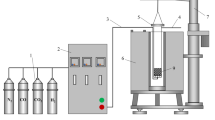

Owing to the change of gas composition in top gas recycling-oxygen blast furnaces compared with traditional blast furnace, many attentions are attracted to the research on iron oxide reduction again. In order to study the influence of H2 and CO on the reduction behavior of pellets, experiments were conducted with H2-N2, CO-N2 or H2-CO gas mixtures at 1173 K by measuring the mass loss, respectively. It was found that the reduction degree increased with increasing the ratio of H2 or CO in the gas mixture, but the reduction with hydrogen was faster than that with carbon monoxide The reduction degree could reach 96.72% after 65 min for the reduction with 50% H2+50% N2, while it is only 53.37% for the reduction with 50% CO+50% N2. The addition of hydrogen to carbon monoxide will accelerate the reduction because the hydrogen molecules are more easily chemisorbed and reacted with iron oxide than carbon monoxide. A scanning electron microscope was used to characterize the structures of reduced samples. Dense structure of iron was obtained in the reduction with hydrogen while the structure of iron showed many small fragments for the reduction with carbon monoxide. At the later stage of reduction with the gas mixtures containing carbon monoxide, the reduction curves showed a descending trend because the rate of carbon deposition caused by the thermal decomposition of carbon monoxide was faster than the rate of oxygen loss. Compared with the reduction with CO-N2 and H2-CO gas mixtures, H2 gas could enhance the carbon deposition while N2 gas would reduce this phenomenon. The results of X-ray diffraction and chemical analysis demonstrated that the carbons ar — mainly in the form of cementite (Fe3C) and graphite in reduced sample.

Similar content being viewed by others

References

ZHANG Jian-liang. The Applied and Fundamental Research on Nitrogen Free Blast Furnace [D]. Beijing: University of Science and Technology Beijing, 2000 (in Chinese).

ZUO Guang-qing, Hirsch A. The Trial of the Top Gas Recycling Blast Furnace at LKABs EBF and Scale-Up [J]. Revue de Métalurgie, 2009, 106(9): 387.

QIN Min-sheng, ZHANG Jian-liang, QI Bao-ming, et al. Advantage of Smelting Vanadium-Titanium Magnetite Ore With Al Oxygen Blast [J]. Iron Steel Va nadium Titanium. 1991, 12(2): 1 (in Chinese).

QIN Min-sheng, GAO Zheng-kai, WANG Guan-lun, et al. Study on Blast Furnace Operation With Al Oxygen Blast [J]. Iron and Steel, 1987, 22(12): 1 (in Chinese).

Yamaoka Hideyuki, Kamei Yasuo. Experimental Study on an Oxygen Blast Furnace Process Using a Smal Test Plant [J]. ISIJ International, 1992, 32(6): 709.

LI Jia-xin, WANG Ping, ZHOU Li-ying, et al. The Reduction of Wustite With High Oxygen Enrichment and High Injection of Hydrogenous Fuel [J]. ISIJ International, 2007, 47(8): 1097.

El-eassy A A. Gaseous Reduction of Fe2O3 Compacts at 600 to 1050 ° [J]. Journal of Materials Science, 1986, 21(11): 3889.

MA Li. Kinetics Study on Iron Ore Reduction With Hydrogen Enriched Gas [D]. Shenyang: Northeastern University, 2007 (in Chinese).

LAN Rong-zong, WANG Jing-song, HAN Yi-hua, et al. Reduction Behavior of Sinter Based on Top Gas Recycling-Oxygen Blast Furnace [J]. Journal of Iron and Steel Research, International, 2012, 19(9): 13.

HUANG Xi-hu. The Principle of Ferrous Metalurgy [M]. Beijing: Metalurgical Industry Press, 2007 (in Chinese).

JIN Yong-long, HE Zhi-jun, GUAN Zhi-gang, et al. Practice and Theoretical Analysis About Effect of H2 Content on Iron-making Process [J]. Iron and Steel, 2001, 2(5): 15 (in Chinese).

El-Geassy A A, Shehata K A, Ezz S Y. Mechanism of Iron-Oxide Reduction With Hydrogen-Carbon Monoxide Mixtures [J]. Transaction ISIJ, 1977, 17(11): 629.

John D H S, Mathew S P, Hayes P C. The Breakdown of Dense Iron Layers on Wustite in CO/CO and H/H2O Systems [J]. Metalurgical Transactions, 1984, 15B(2): 701.

Riecke E, Bohnenkamp K, Engel H J. The Reduction of Wustite With Mixtures of Hydrogen-Steam and Carbon Monoxi de Dioxide Mixtures [J]. Arch Eisenhutenw, 1967, 38(4): 249.

DENG Shou-qiang, CHE Chuan-ren, YAN Li-juan. Study on Carburization of Iron in Upper Part of Blast Furnace [J]. Iron and Steel, 1993, 28(12): 12 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Basic Research Program (973 Program) of China (2012CB720401); National Key Technology Research and Development Program in 12th Five-Year Plan of China (2011BAC01B02)

Rights and permissions

About this article

Cite this article

Zuo, Xj., Wang, Js., An, Xw. et al. Reduction Behaviors of Pellets Under Different Reducing Potentials. J. Iron Steel Res. Int. 20, 12–18 (2013). https://doi.org/10.1016/S1006-706X(13)60210-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(13)60210-1