Abstract

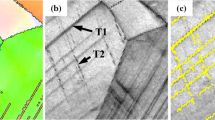

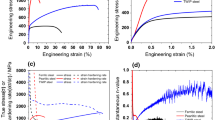

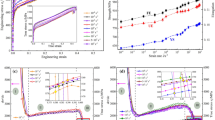

A comparative analysis of formability was investigated between Fe-Mn-C twinning induced plasticity steel with different Mn contents and interstitial-free steel. Tensile test combing with the morphology of fracture reveals that element Mn is helpful for the forming of inclusion or panicles with film or rod shapes inducing the crack initiation and propagation. During stamping process, twinning induced plasticity steel without earing shows better anisotropy than interstitial-free steel because a typical <111> fiber texture forms accompanied by a weaker <100> fiber texture. The difference between the two steels is not evident during Erichsen cone cupping test, but the result of cone cupping test indicates that the twinning induced plasticity steel has superior drawing ability compared with interstitial-free steel. The different performances can be attributed to the different deformation mechanism during cupping test. FLD (forming limit diagram) of tested steels further suggests twinning induced plasticity steel has slightly superior deep drawability but low stretchability than that of IF steel, whose FLD0 value can reach 30%.

Similar content being viewed by others

References

Bleck W. Cold-Rolled, High-Strength Sheet Steels for Auto Applications [J]. JOM, 1996, 48(7): 26.

Grössel O, Krüger L, Frommeyer G, et al. High Strength FeMn-(Al, Si) TRIP/TWIP Steels Development—Properties—Application [J]. Int J Plasticity, 2000, 16(10): 1391.

Chen X M, Witmer D A, Kamura M, et al. Metal Forming Characterization and Simulation of Advanced High Strength Steels [J]. SAE Tmnsactions, 2004, 113(5): 472.

Chen X M, Witmer D A, Kamura M, et al. Metal Forming Characterization and Simulation of Advanced High Strength Steels [J]. SAE Tmnsactions, 2001, 110(5): 926.

Shiekhelsouk M N, Favier V, Inal K, et al. Modelling the Behaviour of Polycrystalline Austenitic Steel With Twinning-Induced Plasticity Effect [J]. Int J Plasticity, 2009, 25(1): 105.

Chung K, Alm K, Yoo D H, et al. Formability of TWIP (Twinning Induced Plasticity) Automotive Sheets [J]. Int J Plasticity, 2011, 27(1): 52.

DING Hao, DING Hua, QIU Chun-lin, et al. Formability of TRIP/TWIP Steel Containing Manganese of 18.8% [J]. Journal of Iron and Steel Research, International, 2011, 18(1): 36.

LI Hong-ying. Analysis of Fracture of Metallic Tensile Specimen [J]. Shanxi Datong University Journal: Science, 2011, 27(1): 76 (in Chinese).

DAI Yang-juan, TANG Di, MI Zhen-li, et al. Study on the Microstructure Characteristic of Fe-23Mn-O. 6C TWIP Steel [J]. Material and Heat Treatment, 2010, 39(2): 132 (in Chinese).

Hong S, Shin S Y, Kim H S, et al. Effects of Inclusions on Delayed Fracture Properties of Three Twinning Induced Plasticity (TWIP) Steels [J]. Metall Mater Trans, 2013, 44A(2): 776.

CHEN Yu, ZHONG Ding-zhong, XIE Hua, et al. Analysis and Application of Hot Rolled Deep Drawing Steel [J]. Iron and Steel, 2000, 35(8): 37 (in Chinese).

Kishor N, Ravi Kumar D. Optimization of Initial Blank Shape to Minimize Earing in Deep Drawing Using Finite Element Method [J]. J Mater Process Tech, 2002, 130-131: 20.

Jiménez J A, Frommeyer G. Analysis of the Microstructure Evolution During Tensile Testing at Room Temperature of High-Manganese Austenitic Steel [J]. Mater Charact, 2010, 61(2): 221.

Samajdar I, Verlinden B, Kestens L, et al. Physical Parameters Related to the Developments of Recrystallization Textures in an Ultra-low Carbon Steel [J]. Acta Mater, 1998, 47(1): 55.

FANG Xiu-hui, YANG Ping, LU Fa-yun, et al. The Characteristic of Texture Evolution and Texture Weaken by Twin of High Manganese TWIP in Tensile Test [J]. Journal of Wuhan University of Science and Technology, 2011, 34(6): 424 (in Chinese).

YU Yan, SONG Qi-feng, CHE Chang, et al. Applying Study on Cone Cupping Method for Shaping Property of Car Deep Drawing Plates [J]. Metal Forming Technology, 2004, 22(3): 56 (in Chinese).

LIU Ying, LI Yuan-yuan, LI Wei. Stamping Formability of ZE10 Magnesium Alloy Sheets [J]. Journal of Rare Earths, 2007, 25: 480 (in Chinese).

Gutierrez-Urrutia I, Raabe D. Dislocation and Twin Substructure Evolution During Strain Hardening of an Fc-22wt. % Mn-0.6wt. %C TWIP Steel Observed by Electron Channeling Contrast Imaging [J]. Acta Mater, 2011, 59(16): 6449.

Hecker S S. Simple Technique for Determining Forn1ing Limit Curves [J]. Sheet Metal Industries, 1975. 52(11): 671.

Gupta A K, Ravi Kumar D. Formability of Galvanized Interstitial-Free Steel Sheets [J]. J Mater Process Tech, 2006, 172(2): 225.

Xu L, Barlat F, Ahn D C, et al. Forming Limit and Fracture Mechanism of Ferritic Stainless Steel Sheets [J]. Mat Sci Eng, 2011, 528A(7): 3113.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National High-Technology Research and Development Program of China (200BAA03E502)

Rights and permissions

About this article

Cite this article

Huang, Y., Zhao, Am., Mi, Zl. et al. Formability of Fe-Mn-C Twinning Induced Plasticity Steel. J. Iron Steel Res. Int. 20, 111–117 (2013). https://doi.org/10.1016/S1006-706X(13)60205-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(13)60205-8