Abstract

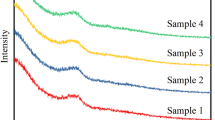

The thermal conductivity of the mould fluxes containing transition metal oxides was measured by hotline method at different temperatures. The relationship between the thermal conductivity of mold fluxes and the contents of transition metal oxides was discussed. The synthetic slags were composed of 30.0%–35.4% CaO, 34.7%–38.6% SiO2, 6% Al2O3, 9% Na2O, 14.4% CaF2, 0–4% Cr2O3 and 0–8% MnO in mass percent. The results indicated that Cr2O3 and MnO had a negative effect on thermal conductivity of mold fluxes. The thermal conductivity of mold fluxes was about 0.25–0.55 W/(m · K) when the temperature reached 1300 °C, and it increased sharply to about 1.32–1.99 W/(m · K) when the temperature reduced from 1300 to 1000 °C. The thermal conductivity of mold fluxes containing Cr2O3 and MnO was 10%–25% lower than those of original fluxes. The decrease in thermal conductivity was attributed to the change of molecular structure of mold fluxes. In addition, the poor integrity and regulation of polycrystal structure, complexity of crystal structure, and effects of impurities in the boundary and lattice distortion leaded to the reduction in the thermal conductivity. Na2CrO4, Mn2SiO4 and other minor phases were also found in the samples containing Cr2O3 and MnO, respectively.

Similar content being viewed by others

References

Nakada H, Susa M, Seko Y, et al. Mechanism of Heat Transfer Reduction by Crystallization of Mold Flux for Continuous Casting [J]. ISIJ Int, 2008, 48(4): 446.

Wen G H, Sridhar S, Tang P, et al. Development of Fluoride-Free Mold Powders for Peritectic Steel Slab Casting [J]. ISIJ Int, 2007, 47(8): 1117.

Mills K C, Fox A B, Thackray R P, et al. The Performance and Properties of Mould Fluxes [C]//Karen du Toit, Nazli Mamdoo. VII International Conference on Molten Slags, Fluxes and Salts. Johnnesburg: Camera Press, 2004: 713.

LONG Xiao, HE Sheng-ping, XU Jian-fei, et al. Properties of High Basicity Mould Fluxes for Peritectic Steel Slab Casting [J]. Journal of Iron and Steel Research, International, 2012, 19(7): 39.

Yamauchi A, Sorimachi K, Sakuraya T, et al. Heat Transfer Between Mold and Slab Through Mold Flux Film in Continuous Casting of Steel [J]. Tetsu-to-Hagané, 1993, 79(2): 167 (in Japanese).

Ohmiya S, Tacke K H, Schwerdtfeger K. Heat Transfer Through Layers of Casting Fluxes [J]. Ironmaking and Steelmaking, 1983, 10(1): 24.

Yamauchi A, Sorimachi K, Sakuraya T, et al. Heat Transfer Between Mold and Strand Through Mold Flux Film in Continuous Casting of Steel [J]. ISIJ Int, 1993, 33(1): 145.

Kawamoto M, Tsukaguchi Y, Nishida N, et al. Improvement of the Initial Stage of Solidification by Using Mild Cooling Mold Powder [J]. ISIJ Int, 1997, 37(2): 134.

Hao Z Q, Chen W Q, Liooold C. Effect of Titania Absorption Into a Mold Flux on the Heat Transfer Between the Mold and the Slab in the Continuous Casting of Titanium-Stabilized Stainless Steel [J]. Metall Mater Trans, 2010, 41B(4): 805.

Diao J, Xie B, Wang N H, et al. Effect of Transition Metal Oxides on Radiative Heat Transfer Through Mold Flux Film in Continuous Casting of Steel [J]. ISIJ Int, 2007, 47(7): 1297.

Diao J, Xie B, Xiao J P. Experimental Investigation Into Radiative Heat Transfer Characteristics for Mould Fluxes Containing Transition Oxides [J]. Ironmaking and Steelmaking, 2009, 36(8): 613.

WANG Xin-yue, JIN Shan-tong. Change in Composition of Mold Flux and Its Effects on Properties During Casting 304HC Stainless Steel [J]. Iron and Steel, 2006, 41(11): 20 (in Chinese).

Choi S Y, Lee D H, Shin D W, et al. Properties of F-Free Glass System as a Mold Flux: Viscosity, Thermal Conductivity and Crystallization Behavior [J]. J Non-cryst Solids, 2004, 345–346(10): 157.

Nagata K, Susa M, Goto K. Thermal Conductivities of Slags for Ironmaking and Steelmaking [J]. Tetsu-to-Hagané, 1983, 69(11): 1418 (in Japanese).

ZHANG Hua, ZHAO Wen-zhu. Thermal Measurement Instrument [M]. Beijing: Metallurgical Industry Press, 2006 (in Chinese).

Kang Y, Morita K. Thermal Conductivity of the CaO-Al2O3-SiO2 System [J]. ISIJ Int, 2006, 46(3): 420.

XI Tong-geng. Thermal-Physical Property Science of Inorganic Materials [M]. Shanghai: Shanghai Science and Technology Press, 1981 (in Chinese).

Department of Geological Rock Ore Teaching and Research, Peking University. Optical Mineralogy [M]. Beijing: Geological Publishing Press, 1979 (in Chinese).

Ozawa S, Susa M, Goto T, et al. Lattice and Radiation Conductivities for Mould Fluxes From the Perspective of Degree of Crystallinity [J]. ISIJ Int, 2006, 46(3): 419.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by Doctor Programs Foundation of Education Ministry of China (200806110006)

Rights and permissions

About this article

Cite this article

Qiu, X., Xie, B., Qing, Xm. et al. Effects of Transition Metal Oxides on Thermal Conductivity of Mould Fluxes. J. Iron Steel Res. Int. 20, 27–32 (2013). https://doi.org/10.1016/S1006-706X(13)60192-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(13)60192-2