Abstract

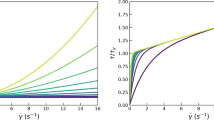

Based on the Al2O3 inclusion analysis of low-carbon aluminum killed steel in tundish of a domestic steel company and fractal theory analysis, a mathematical model of fractal agglomerating-growth of Al2O3 inclusions in tundish was established. The results indicated that: large swirl flows exist in both sides of inlet, space between weir and dam, and large zone above outlet, in which monomer and agglomerated inclusion particles accumulate easily; the agglomerated inclusions with hydrodynamic diameter of 6–9.8 μm were quickly generated less than 16 s, but those inclusions with hydrodynamic diameter more than 11 μm were difficult to form; the number density of agglomerated inclusion rapidly increased first, then slowly reduced, so the form and quantity distribution of agglomerated inclusions can be controlled by controlling the residence time of inclusion particles in tundish.

Similar content being viewed by others

References

Zhang Li-feng, Taniguchi S, Cai Kai-ke. Fluid Flow and Inclusion Removal in Continuous Casting Tundish [J]. Metallurgical and Materials Transaction, 2000, 31B(2): 253.

Taniguchi S, Kikuchi A. Mechanisms of Collision and Coagulation Between Fine Particles in Fluid [J]. ISIJ International, 1992, 78(4): 527.

ZHANG Jiong-ming, DENG Feng-qin, WANG Wen-ke, et al. Numerical Simulation of Dimensionless Inclusion Concentration in T-Shape Tundishes [J]. Journal of University of Science and Technology Beijing, 2004, 26(3): 247 (in Chinese).

Lei Hong, Wang Lian-ze, Wu Zi-niu, et al. Collision and Coalescence of Alumina Particles in the Vertical Bending Continuous Caster [J]. ISIJ International, 2002, 42(7): 717.

Smoluchowski V M. Mathematical Theory of the Kinetics of the Coagulation of Colloidal Particle [J]. Physical Chemistry Chemical Physics, 1917, 127(92): 155.

Nakaoka T, Taniguchi S, Matsumoto K, et al. Particle-Size-Grouping Method of Inclusion Agglomeration and Its Application to Water Model Experiments [J]. ISIJ International, 2001, 41(10): 1103.

Shirabe K, Szekely J. A Mathematical Model of Fluid Flow and Inclusion Coalescence in the RH Vacuum Degassing System [J]. Transactions of the Iron and Steel Institute of Japan, 1983, 23(6): 465.

Sinha A K, Sahai Y. Mathematical Modeling of Inclusion Transport and Removal in Continuous Casting Tundishes [J]. ISIJ International, 1993, 33(5): 556.

ZHANG Ji-zhong. Fractal [M]. 2nd ed. Beijing: Tsinghua University Press, 2011 (in Chinese).

LI Hong, GUO Luo-fang, PAN Yong-hong. Simulation on Agglomeration of Inclusions in Steel With DLA Model Under Three-Dimensional Condition [J]. The Chinese Journal of Process Engineering, 2009, 9(S1): 312 (in Chinese).

NING Lin-xin, LI Hong, ZHANG Jiong-ming, et al. Research on Steel Inclusion’s Fractal Dimension [J]. Journal of Iron and Steel Research, 2006, 28(4): 343 (in Chinese).

Gmachowski L. Estimation of the Dynamic Size of Fractal Aggregates [J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2000, 170(2/3): 209.

Tozawa H, Kato Y, Sorimachi K, et al. Agglomeration and Flotation of Alumina Clusters in Molten Steel [J]. ISIJ International, 1999, 39(5): 426.

GUO Luo-fang, LI Hong, WANG Yao, et al. Applying Fractal Theory to Study the Agglomeration of Solid Inclusion Particles in Liquid Steel and Floating Characteristics [J]. Physics Examination and Testing, 2012, 30(4): 22 (in Chinese).

Nakanishi K, Szekely J. Deoxidation Kinetics in a Turbulent Flow Field [J]. Transactions of the Iron and Steel Institute of Japan, 1975, 15(10): 522.

Miki Y, Shimada Y, Thomas B G, et al. Model of Inclusion Removal During RH Degassing of Steel [J]. Iron and Steelmaker, 1997, 24(8): 31.

Taniguchi S, Kikuchi A. Model Experiment on the Coagulation of Inclusion Particles in Liquid Steel [J]. ISIJ International, 1996, 36(S1): 117.

GUO Luo-fang, LI Hong, WANG Yao, et al. Floating Critical Diameter and Removal Ratio of Al2O3 Particles in Interface Between Steel and Slag [J]. Iron and Steel, 2012, 47(2): 23 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (51074020)

Rights and permissions

About this article

Cite this article

Guo, Lf., Li, H., Ling, Ht. et al. Numerical Simulation of Fractal Agglomerating-Growth of Al2O3 Inclusions in Tundish. J. Iron Steel Res. Int. 20, 7–12 (2013). https://doi.org/10.1016/S1006-706X(13)60189-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(13)60189-2