Abstract

The empirical models of sulfide capacity calculated by traditional optical basicity do not consider the charge compensation of alkaline metal ions to Al3+ in the molten slags, so that the deviations between the calculated values and measured ones of sulfide capacity are inevitable. The relation between sulfide capacity and the corrected optical basicity put forward by Mills considering the charge compensation was investigated. Combined with the relation between sulfide capacity and temperatures, a novel and accurate calculation model of sulfide capacity was proposed, which was applied to calculate the sulfide capacities of CaO-Al2O3-SiO2-MgO and CaO-Al2O3-SiO2-MgO-TiO2 sys-tems, where the sum of the CaO and MgO concentrations in the slags must be not lower than the Al2O3 concentra-tion. It was also found that the calculated values were in a good agreement with the measured values, and the mean deviations were 2.57 and 2.65 %, respectively.

Similar content being viewed by others

References

Fincham C J B, Richardson F D. The Behaviour of Sulphur in Silicate and Aluminate Ms [J]. Proceedings of the Royal Society of London Series, 1954, 223A(1152): 40.

Nzotta M M, Sichen Du, Seetharaman S. Sulphide Capacities in Some Multi Component Slag Systems [J]. ISIJ International, 1998. 38(11):1170.

Drakaliysky E, Sichen Du, Seetharaman S. An Experimental Study of the Sulphide Capacities in the System Al2O3-CaO-SiO2 [J]. Canadian Metallurgical Quarterly, 1997, 36(2): 110.

Taniguchi Y, Sano N, Seetharaman S. Sulphide Capacities of CaO-Al2O3-SiO2-MgO-MnO Slags in the Temperature Range 1673–1773 K [J]. ISTJ International, 2009, 49(2): 156.

STIT Cheng-bin, YANG Xue-min, JIAO Jin-sha, et al. A Sulphide Capacity Prediction Model of CaO-SiO2-MgO-Al2O3 Ironmaking Slags Basedon the Ion and Molecule Coexistence Theory [J]. ISIJ International, 2010. 50(10): 1362.

Sosinsky D J, Sommerville I D. The Composition and Temperature Dependence of the Sulfide Capacity of Metallurgical Slags [J]. Metallurgical and Materials Transactions, 1986, 17B(2): 331.

Young R W, Duffy J A, Hassal G J. et al. Use of Optical Basicity Concept for Determining Phosphorus and Sulphur Slag-Metal Partitions [J]. Ironmaking and Steelmaking, 1992, 19(3): 201.

Shankar A, Gornerup M, Lahiri A K, et al. Sulfide Capacity of High Alumina Blast Furnace Slags [J]. Metalurgical and Materials Transactions, 2006, 37B(6): 941.

Zhang G H, Xue Q G, Chou K C. Study on Relation Between Viscosity and Electrical Conductivity of Aluminosilicate Melts [J]. Ironmaking and Steelmaking, 2011, 38(2): 149.

Shu Q F. A Viscosity Estimation Model for Molten Slags in Al2O3-CaOMgSiO2 System [J]. Steel Research International, 2009, 80(2): 107.

Mills K C, Sridhar S. Viscosities of Ironmaking and Steel-making Slags [J]. Ironmaking and Steelmaking, 1999, 26(4): 262.

Turkogan E T. Slags and Fluxes for Ferrous Ladle Metalurgy [J]. Tronmaking and Steelmaking, 1985, 12(2). 64.

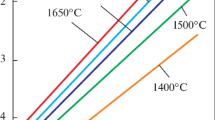

Gornerup M, Wijk O. Sulphide Capacities of CaO-Al2O3-SiO3 Slags at 1550, 1600 and 1650 °C [J]. Scandinavian Journal of Metalurgy, 1996, 25(3): 103.

Hayakawa H, Hasegawa M, Oh-Nuki K, et al. Sulphide Capacities of CaOSiO2Al2O3-MgO Slags [J]. Steel Research International, 2006, 77(1): 14.

Duffy J A, Ingram M D. An Interpretation of Glass Chemistry in Terms of the Optical Basicity Concept [J]. Journal of Non-Crystalline Solids, 1976, 21(3): 373.

YANG Xue-min, JIAO Jin-sha, DING Ru-cai, et al. A Thermodynamic Model for Calculating Sulphur Distribution Ratio Between CaO-Al2O3-SiO2-MgO Ironmaking Slags and Carbon Saturated Hot Metal Based on the Iron and Molecule Coexistence Theory [J]. ISIJ International, 2009, 49(12): 1828.

Ota M, Kubo T, Morita K. Effects of CaF2, MgO and Si O2 Addition on Sulfide Capacities of the CaO-Al2O3 Slag [J]. Tetsu-to-Hagane, 2003, 89(7): 742 (in Japanese).

Tang Xin, Xu Chushao. Sulphur Distribution Between CaO-SiTiO2-Al2O3-MgO Slag and Carbon-Saturated Iron at 1773 K [J]. TSIJ International, 1995, 35(4): 367.

Karsrud K. Sulfide Capacities of Synthetic Blast Furnace Slags at 1500 °C [J]. Scandinavian Journal of Metallurgy, 1984, 13(3): 144.

Seo J D, Kim S H. The Sulphide Capacity of CaO-Al2O3-Si()2-MgO (- FeO) Smelting Reduction Slags [J]. Steel Research International, 1999, 70(6): 203.

Sommerville I D, Bell H B. The Behavior of Titania in Metal lurgical Slags [J]. Canadian Metallurgical Quarterly, 1982(2): 145.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Foundation Item:Item Sponsored by National Natural Science Foundation of China (51090384)

Rights and permissions

About this article

Cite this article

Ren, Zs., Hu, Xj. & Chou, Kc. Calculation and Analysis of Sulfide Capacities for CaO-Al2O3-SiO2-MgO-TiO2 Slags. J. Iron Steel Res. Int. 20, 21–25 (2013). https://doi.org/10.1016/S1006-706X(13)60151-X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(13)60151-X