Abstract

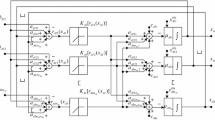

In order to increase the precion of flatness control, considering the principle and the measured data of rolling process essence, the theory-intelligent dynamic matrix model of flatness control is established by using theory and intelligent methods synthetically. The network model for rapidly calculating the theory effective matrix is established by the BP network optimized by the particle swarm algorithm. The network model for rapidly calculating the measurement effective matrix is established by the RBF network optimized by the cluster algorithm. The flatness control model can track the practical situation of rolling process by on-line self-learning. The scheme for flatness control quantity calculation is established by combining the theory control matrix and the measurement control matrix. The simulation result indicates that the establishment of theory-intelligent dynamic matrix model of flatness control with stable control process and high precision supplies a new way and method for studying flatness on-line control model.

Similar content being viewed by others

References

LIU Hong-min, JIA Chun-yu, SHAN Xiu-ying. Appication of Inteligent Methods in Flatness Control [J]. Journal of Yanshan University, 2010, 34(1): 1 (in Chinese).

PENG Yan, SUN Jian-liang, LIU Hong-min. Development of Dynamic Model Building and Simulation of Rolling Mill System Based on Shape and Thickness Control [J]. Journal of Yanshan University, 2010, 34(1): 6 (in Chinese).

PENG Yan, LIU Hong-min. Pattern Recogntion Method Progress of Measured Signals of Shape in Cold Rolling [J]. Journal of Yanshan University, 2003, 27(2): 142 (in Chinese).

FAN You-qin, DUAN Zhen-yong. Deformation of Tension-Measuring Roll Formed by Beams of Pieces Construction [J]. Journal of Yanshan University, 1992, 16(4): 317 (in Chinese).

LIU Hong-min. Three-Dimensional Rolling Theory and Its Applications [M]. Beijing: Science Press, 1999 (in Chinese).

ZHANG Xiu-ling. Research on Intelligent Control and Recognition of Flatness for Cold Strip Mill [D]. Qinhuangdao: Yanshan University, 2002 (in Chinese).

ZHANG Xiu-ling, LIU Hong-min. Transfer Matrix Method of Flatness Control [J]. Chinese Journal of Mechanical Engineering, 2003, 39(11): 100 (in Chinese).

LIU Hong-min, ZHANG Xiu-ling, WANG Ying-rui. Transfer Matrix Method of Flatness Control for Strip Mills [J]. Journal of Materials Processing Technology, 2005, 166(2): 237.

HE Hai-tao. Research on Flatness On-Line Intelligent Control for the Wide Strip Steel Cold Mill [D]. Qinhuangdao: Yanshan University, 2008 (in Chinese).

LIU Hong-min, HE Hai-tao, SHAN Xiu-ying, et al. Flatness Control Based on Dynamic Effective Matrix for Cold Strip Mills [J]. Chinese Journal of Mechanical Engineering, 2009, 22(2): 287.

PENG Yan, ZHENG Zhen-zhong, WANG Jian-guo. Influence and Compensating Means of Profile in Strip Flatness Measuring and Controlling of Reversible Rolled Strip Profile [J]. Journal of Yanshan University, 1999, 23(1): 76 (in Chinese).

JIA Chun-yu, REN Yu-bo, NI Yu-hui. Fuzzy Control on Strip Shape of 20-High Sendzimir Mill [J]. Journal of Yanshan University, 1999, 23(4): 352 (in Chinese).

LI Yuan, LIU Wen-zhong, SUN Yi-kang. Application of Neural Network to Prediction Rolling Force for the Finisher [J]. Iron and Steel, 1996, 31(1): 54 (in Chinese).

WU Gang, SUN Yi-kang. Application of Multivariable Fuzzy Predictive Control in AGC-AFC [J]. Journal of University of Science and Technology Beijing, 1999, 21(4): 403 (in Chinese).

SUN Te-kai, ZHAO Yong-he. Research on Prole Controlling Characteristics of WRS Mill [J]. Journal of Yanshan University, 1991, 15(2): 139 (in Chinese).

PENG Yan, ZHENG Zhen-zhong, LIU Hong-min. Simulation Research of Cold Rolled Strip Shape Control in 6-Roller HC Mill [J]. China Mechanical Engineering, 2000, 11(9): 1061 (in Chinese).

ZHOU Kai-li, KANG Yao-hong. Neural Network Model and Its Simulation Programming by MATLAB [M]. Beijing: Tsinghua University Press, 2005 (in Chinese).

WANG Hong-yuan, SHI Guo-dong. Artificial Neural Network Technology and Its Applications [M]. Beijing: China Petrochemical Press, 2002 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National High-Tech Research and Development Project of China (2009AA04Z143); Natural Science Foundation of Hebei Province of China (E2006001038); Hebei Provincial Science and Technology Project of China (10212101D)

Rights and permissions

About this article

Cite this article

Liu, Hm., Shan, Xy. & Jia, Cy. Theory-Intelligent Dynamic Matrix Model of Flatness Control for Cold Rolled Strips. J. Iron Steel Res. Int. 20, 1–7 (2013). https://doi.org/10.1016/S1006-706X(13)60133-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(13)60133-8