Abstract

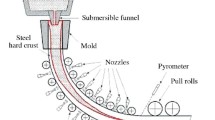

Ultra-fast cooling (UFC) is an advanced technology in hot rolling field. Through this technology, great changes on the run-out table are produced in the strip cooling process. In order to adapt to these changes, a new generation of hot strip cooling control system after rolling was developed based on the UFC basic principle. The system can not only accomplish temperature of UFC delivery side, coiling temperature, cooling rate, etc, and multi-objective accuracy control, but also offer more flexibility and new attractive possibilities in terms of cooling pattern on the runout table, which could be of prime importance for the production of some difficult steels. In addition, through the time-velocity-distance (TVD) profile prediction combined with speed feed-forward control and coiling temperature feedback control, the coiling temperature control precision can be effectively improved during accelerative rolling in the system. At present, the system has been successfully used in the conventional strip production line and CSP short process production line, and its application effect is perfect.

Similar content being viewed by others

References

Guo R M. Heat Transfer of Laminar Flow Cooling During Strip Acceleration on Hot Strip Mill Runout Tables [J]. Transactions of the ISS, 1993, 20(8): 49.

ZHANG Dian-hua, WANG Bing-xing, ZHOU Na, et al. Cooling Efficiency of Laminar Cooling System for Plate Mill [J]. Journal of Iron and Steel Research, International, 2008, 15(5): 24.

WANG Guo-dong. The New Generation TMCP With the Key Technology of Ultra Fast Cooling [J]. Shanghai Metals, 2008, 30(2): 1 (in Chinese).

Houyoux C, Herman J C, Simon P, et al. Metallurgical Aspects of Ultra Fast Cooling on a Hot Strip Mill [J]. Revue de Metallurgie, 1997, 97, 58.

WANG Guo-dong. New Generation TMCP and Innovative Hot Rolling Process [J], Journal of Northeastern University: Natural Science, 2009, 30(7): 913 (in Chinese).

NING Li-guo. Hot Strip Laminar Cooling Control and Optimization [D]. CHANGSHA: CENTRAL SOUTH UNIVERSITY, 2007 (in Chinese).

XIE Hai-bo, LIU Xiang-hua, WANG Guo-dong, et al. Optimization and Model of Laminar Cooling Control System for Hot Strip Mills [J], Journal of Iron and Steel Research, International, 2006, 13(1): 18.

Chen S J, Biswas S K, Han L F, et al. Modeling and Analysis of Controlled Cooling for Hot Moving Metal Plates [J]. Monit Control Manuf Processes, 1990, 44(6): 465.

CAI Zheng, WANG Guo-dong, LIU Xiang-hua, et al. Model of Hot-Rolled Strip Temperature Distribution During Laminar Cooling [J]. Steel Rolling, 1998, 33(8): 31 (in Chinese).

Biswas S K, Chen S J, Satyanarayana A. Optimal Temperature Tracking for Accelerated Cooling Processes in Hot Rolling of Steel [J]. Dynamics and Control, 1997, 7(4): 327.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Foundation Item: Item Sponsored by National Natural Science and Technology Support Program in 12th Five-Year Plan of China (2012BAF04B01)

Rights and permissions

About this article

Cite this article

Li, Hj., Li, Zl., Yuan, G. et al. Development of New Generation Cooling Control System After Rolling in Hot Rolled Strip Based on UFC. J. Iron Steel Res. Int. 20, 29–34 (2013). https://doi.org/10.1016/S1006-706X(13)60122-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(13)60122-3