Abstract

The microstructure and mechanical properties of nodular cast iron produced by the melted metal die forging process (MMDF for short) were experimentally researched. The main obtained results are: the nodular cast iron produced by this process can be machined as easy as traditional one only if holding at the remained temperature for 4 h; its strength and plasticity are obviously higher than those of traditional ones; the graphite size arrived at grade 8, and the graphite spheroidizing arrived at grade 1 or 2, but a streamline molded distribution of the graphite slightly appeared. Both of the strength and plasticity increased with the pressure when the pressure holding time was larger than its critical value. A new way to produce high properties nodular cast iron was provided.

Similar content being viewed by others

References

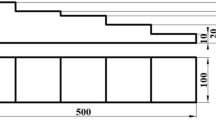

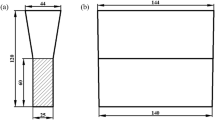

XING Shu-ming, BAO Pei-wei, Melted Metal Die Forging [M]. Beijing: National Defense Industry Press, 2011 (in Chinese).

Souissi Slim, Ben Amar Mohamed, Bradai Chedly. Microstructure Characterization and Tensile Properties of Direct Squeeze Cast and Gravity Die Cast 2017A Wrought Al Alloy [J]. International Journal of Material Forming, 2011, 4(1): 1.

XING Shu-ming, BAO Pei-wei, LI Nan. Modified Rheological Processing Technology and Its Applications in Iron and Steels [J]. Transactions of Nonferrous Metals Society of China (English Edition), 2010, 20(S3): s993.

Masoumi Mohsen, Hu Henry. Influence of Applied Pressure on Microstructure and Tensile Properties of Squeeze Cast Magnesium Mg-Al-Ca Alloy [J]. Materials Science and Engineering, 2011, 528A(10/11): 3589.

Lee S M, Kang C G. Effect of Solid Fraction on Formability and Mechanical Properties in a Vertical-Type Rheo Squeeze-Casting Process [J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2011, 225(2): 184.

Khodaverdizadeh H. Effects of Applied Pressure on Microstructure and Mechanical Properties of Squeeze Cast Ductile Iron [J]. Materials and Design, 2011, 32(10): 47.

Von Rainer, Kaiser W, Sahm P R, et al. Duktiler Gusseisen-bauteile [J]. Giesserei, 2005 (3): 50 (in German).

Czerwinski F. Size Evolution of the Unmelted Phase During Injection Molding of Semisolid Magnesium Alloys [J]. Scripta Materialia, 2003, 48(4): 327.

ZHANG Qing-lai, WANG Li-li, HU Yong-xue. Plastic Deformation and the A-B Microstructure of the Nodular Cast Iron [J]. Metal Heat Treatment, 2006, 31(12). 25.

GU Ke-cheng, CUI Kai, DING Hui. Mechanical Properties of the Nodular Cast Iron on Slow Loading Condition [J], Transactions of Materials and Heat Treatment, 2002, 23(2): 69.

Murali S, Yong M S. Liquid Forging of Thin Al-Si Structures [J]. Journal of Materials Processing Technology, 2010, 210(10): 1276.

De Brito Crystopher Cardoso, Magalhāes Fabrício Dias, Costa Andre Luiz De Morais. Microstructural Analysis and Tensile Properties of Squeeze Cast Al-7% Mg Alloy [J]. Materials Science Forum, 2010, 643: 119.

Gegel Gerald, Weiss David, Edney William. Properties of B356-T6 Aluminum Cast via Permanent Mold and Advanced Squeeze Cast (ASC) Processes [C]//The Minerals, Metals and Materials Society (TMS). Shape Casting—3rd International Symposium 2009. San Francisco: The Minerals, Metals and Materials Society (TMS), 2009: 27.

Li Y Y, Hu Y, Zhao H D, et al. Vertical Indirect Squeeze Casting Process of an Al-Cu-Mn Alloy Frame Part [C]//Materials Science Forum. Advances in Materials Manufacturing Science and Technology XIII: Modern Design Theory and Methodology, MEMS and Nanotechnology, Material Science and Technology in Manufacturing. Dalian: Trans Tech Publications Ltd, 2009, 628–629: 605.

ZHANG Ke-wu, ZHAO Hai-dong, OUYANG Xiao-xian. Microstructures and Mechanical Properties of Al-Si-Cu-T4 Solidified at Different Squeeze Pressures [J]. Chinese Journal of Nonferrous Metals, 2009, 19(4): 625.

LI Xiang-wei, CHEN Ti-jun, HAO Yuan, et al. Influence of Pouring Temperature on Dendrite Morphology of ZA27 Alloys [J]. Foundry, 2010, 59(7): 704.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (51275031); Innovation Fund for Technology Based Firms of China (11C26211304055)

Rights and permissions

About this article

Cite this article

Li, N., Xing, Sm. & Bao, Pw. Microstructure and Mechanical Properties of Nodular Cast Iron Produced by Melted Metal Die Forging Process. J. Iron Steel Res. Int. 20, 58–62 (2013). https://doi.org/10.1016/S1006-706X(13)60112-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(13)60112-0