Abstract

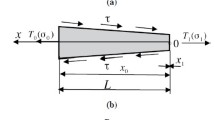

In asymmetric cold rolling, the workpiece is often bent downwards or upwards. A two-dimensional explicit dynamic finite element model with Arbitrary Lagrangian Eulerian (ALE) adaptive meshing technique has been employed to simulate asymmetrical sheet rolling, in which asymmetrical conditions are here due to different roll radii. To validate the simulation, the results of simulation and experiment are compared. Effects of asymmetry due to roll radii mismatch on the normal and shear distributions and on sheet curvature variations are discussed. An optimum roll radii ratio could be found to produce flat sheet. Trials were conducted to investigate the effectiveness of roll radii mismatch as an approach of sheet curvature control. Key words: asymmetrical rolling; finite element method; radii ratio; sheet curvature

Similar content being viewed by others

References

Salimi M, Kadkhodaei M. Slab Analysis of Asymmetrical Sheet Rolling [J]. Journal of Material Processing Technology, 2004, 150(3): 215.

Akbari Mousavi S A A, Ebrahimi S M, Madoliat R. Three Dimensional Numerical Analyses of Asymmetric Rolling [J]. Journal of Material Processing Technology, 2007, 187–188: 725.

Gao H, Ramalingam S C, Barber G C, et al. Analysis of Asymmetrical Cold Rolling With Varying Coefficients of Friction [J]. Journal of Materials Processing Technology, 2002, 124(1/2): 178.

Wronski S, Ghilianu B, Chauveau T, et al. Analysis of Textures Heterogeneity in Cold and Warm Asymmetrically Rolled Aluminium [J]. Materials Characterization, 2011, 62(1): 22.

Ji Y H, Park J J, Kim W J. Finite Element Analysis of Server Deformation in Mg-3Al-1Zn Sheets Through Differential-Speed Rolling With a High Speed Ratio [J]. Materials Science and Engineering, 2007, 454-455A: 570.

ZUO Fang-qing, JIANG Jian-hua, SHAN Ai-dang, et al. Shear Deformation and Grain Refinement in Pure Al by Asymmetric Rolling [J]. Trans Nonferrous Met Soc China, 2008, 18(4): 774.

Lee J K, Lee D N. Texture Control and Grain Refinement of AA1050 Al Alloy Sheets by Asymmetric Rolling [J]. International Journal of Mechanical Sciences, 2008, 50(5): 869.

Wauthier A, Regie H, Formigoni J, et al. The Effects of Asymmetrical Cold Rolling on Kinetics, Grain Size and Texture in IF Steels [J]. Materials Characterization, 2009, 60(2): 90.

JIANG Jian-hua, DING Yi, ZUO Fang-qing, et al. Mechanical Properties and Microstructures of Ultra Fine-Grained Pure Aluminium by Asymmetric Rolling [J]. Scripta Materialia, 2009, 60(10): 905.

Kim W J, Lee J B, Kim W Y, et al. Microstructure and Mechanical Properties of Mg-Al-Zn Alloy Sheets Severely Deformed by Asymmetrical Rolling [J]. Scripta Materialia, 2007, 56(4): 309.

DING Yi, JIANG Jian-hua, SHAN Ai-dang. Microstructures and Mechanical Properties of Commercial Purity Iron Processed by Asymmetric Rolling [J]. Material Science and Engineering, 2009, 509A(1/2): 76.

Hwang Y M, Tzou G Y. Analytical and Experimental Study on Asymmetrical Sheet Rolling [J]. Int J Mech Sci, 1997, 39 (3): 289.

TIAN Yong, GUO Yan-hui, WANG Zhao-dong, et al. Analysis of Rolling Pressure in Asymmetrical Rolling Process by Slab Method [J]. Journal of Iron and Steel Research. International, 2009, 16(4): 22.

Yanagimoto J. Strategic FEM Simulator for Innovation of Rolling Mill and Process [J]. Journal of Materials Processing Technology, 2002, 130–131: 224.

Hibbitt, Karlsson and Sorensen, Inc. ABAQUS/Explicit Users Manual [M]. Version 6.9.

Gudur P P, Salunkhe M A, Dixit U S. A Theoretical Study on the Application of Asymmetric Rolling for the Estimation of Friction [J]. International Journal of Mechanical Sciences, 2008, 50(2): 315.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Basic Research Program of China (2011CB606306-2); Scientific Research Fund for Young Teachers of China (N100307001)

Rights and permissions

About this article

Cite this article

Hao, L., Di, Hs. & Gong, Dy. Analysis of Sheet Curvature in Asymmetrical Cold Rolling. J. Iron Steel Res. Int. 20, 34–37 (2013). https://doi.org/10.1016/S1006-706X(13)60094-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(13)60094-1