Abstract

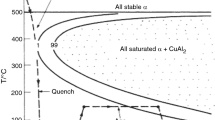

For plate quenching on a roller quenching machine, heat transfer process is investigated. According to the practical online experiment of plate center temperature, average heat transfer coefficient under different conditions and temperature fields are analyzed by numerical simulation. The results show that, at the water temperature of 15 °C, the instantaneous maximum quenching cooling rate is 17.6 °C/s for the plate of 50 mm in thickness in roller quenching process. In the temperature range of 400 — 850 °C, the maximum is 12. 1 °C/s. With the plate surface temperature decreasing, surface heat transfer coefficient increases at first, and reaches the maximum value of about 15 000 W/(m2 • K), and then decreases. The calculated heat transfer coefficients are applied to analyze plate temperature field of different thicknesses, and the difference between the calculated and measured temperature is less than 5%.

Similar content being viewed by others

References

YUAN Guo, WANG Guo-dong, WANG Ri-qing, et al. Development and Application of Steel Plate Heat Treatment Technology and Facilities [J]. Journal of Iron and Steel Research, 2009, 21(5), 1 (in Chinese).

SHAO Zheng-wei. Development Tendency of Process and Equipment of Heat Treatment for Medium and Heavy Plate [J]. Steel Rolling, 2006, 23(4); 37 (in Chinese).

SONG Yao-hua, CAI Cong-qing, CAI Jin-biao. Application and Improvement to the Imported Modernized Heat Treating Roller-Hearth Furnace-Quenching Machine Set [J]. Wide and Heavy Plate, 2002, 8(3): 24 (in Chinese).

Hatta N, Kokado J I, Hanasaki K. Numerical Analysis of Cooling Characteristic for Water Bar [J]. Transactions ISIJ, 1983, 23: 555.

LENG Hao. Study of Heat Transfer With Impinging Circular Liquid Jet [D]. Xi’an: Xi’an Jiaotong University, 2007 (in Chinese).

Chen Shih-jiun, Tseng A A. Spray and Jet Cooling in Steel Rolling [J]. Int J Heat Fluid Flow, 1992, 13(4): 358.

WANG Guo-dong. Strip Shape Control and Homogeneous Cooling Technique [J]. Shanghai Metals, 2007, 29(6): 1 (in Chinese).

Chen S J, Biswas S K, Han L F, et al. Modeling and Analysis of Controlled Cooling for Hot Moving Metal Plates [C] // Symposium of Modeling and Control of Manufacturing Process. ASME PED-Vol. 44. Dallas: American Society of Mechanical Engineers, 1990: 465.

WANG Chao. Research and Application of Quenching Controlling System of Plate Roller Quenching Machine [D]. Shenyang: Northeastern University, 2007 (in Chinese).

Price R F, Fletcher A J. Determination of Surface Heat-Transfer Coefficients During Quenching of Steel Plates [J]. Metals Technology, 1980, 7: 203.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Basic Research Program (973 Program) of China (2010CB630800)

Rights and permissions

About this article

Cite this article

Wang, C., Wang, Zd., Yuan, G. et al. Heat Transfer During Quenching by Plate Roller Quenching Machine. J. Iron Steel Res. Int. 20, 1–5 (2013). https://doi.org/10.1016/S1006-706X(13)60088-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(13)60088-6