Abstract

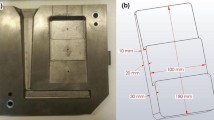

It has been shown that it is possible to produce thin wall ductile iron (TWDI) castings of considerable length using an Archimedes spirals with a wall of 1, 2 or 3 mm in thickness. The fluidities for different moulding materials [(classical mould, chemically bonded silica sand and chemically bonded low-density alumina-silicate ceramic sand (LDASC)], chemical composition, and pouring temperature were estimated. There is a significant temperature drop in thin sections (contrary to typical sections) during the mould filling. A profile of real temperature drop is presented along with theoretical predictions. The high temperature drop of liquid iron results in an increased cooling rate (before the eutectic equilibrium solidification temperature), which in turn affects the solidification and micro-structure of TWDI castings. Microstructures were characterized quantitatively using an image analyser. Structure parameters for different wall thicknesses and moulding materials (graphite nodule count, ferrite and cementite fraction) are plotted, which is versus distance from the entrance to the mould cavity. It has been shown that the thin wall castings have a gradient structure. Moreover, a strong influence of LDASC sand (material with low ability to absorb the heat) on the structure parameters of TWDI castings is presented.

Similar content being viewed by others

References

Fras E, Górny M, Stachurski W. Problem of Super-Thin Wall Nodular Cast Iron Castings [J]. Foundry Review, 2006, 56(5/6): 230.

Katz S, Warren A. Thin Wall Iron Castings; Planning the Future [J]. Foundry Management and Technology, 1997, 125(6): 34.

David P, Massone J, Boeri R, et al. Mechanical Properties of Thin Wall Ductile Iron-Influence of Carbon Equivalent and Graphite Distribution [J]. Iron and Steel Institute of Japan, 2004, 44(7): 1180.

Stefanescu D M, Ruxanda R, Dix L P. The Metallurgy and Tensile Mechanical Properties of Thin Wall Spheroidal Graphite Iron [J]. International Journal of Cast Metals Research, 2003, 16(1/2/3): 319.

Javaid A, Thomson J, Davis K G, et al. Effect of Microstructure on the Mechanical Properties of Thin-Wall Ductile Iron Castings [J]. AFS Transactions, 2001, 111: 1097.

Stefanescu D M. Properties and Selection: Irons, Steels and High-Performance Alloys [M]. 10th ed. Material Park: ASM International, 1990.

Moroi G, Anterkowitsch H, Paschen P. The Reduction in Energy Consumption in the Metallurgy [J]. Berg-Hüttenmannische Monatschafe, 1997, 142(1); 4.

Mampaey F, Xu Z A. Mould Filling and Solidification of a Thin-Wall Ductile Iron Casting [J]. AFS Transactions, 1998, 105: 95.

Fras E, Górny M, Kapturkiewicz W, et al. Chilling Tendency and Chill of Cast Iron [J]. Tsinghua Science and Technology, 2008, 13(2): 177.

Fras E, Górny M, Lopez H F. Gradient Structure of Ductile Iron [J]. Archives of Foundry, 2006, 2(2): 39.

Iafari H, Idris M, Ourdjini A, et al. Influence of Gating System, Sand Grain Size, and Mould Coating on Microstructure and Mechanical Properties of Thin-Wall Ductile Iron [J]. Journal of Iron and Steel Research, International, 2010, 17(12): 38.

Longa W. Casting Solidification [M]. Katowice: Slask, 1985 (in Polish).

Showman R E, Aufderheide R C, Yeomans N. Ironing Out Thin-Wall Casting Defects [J]. Modern Casting, 2006, 96(7): 29.

Midea T, Shah J V. Mould Material Thermophysical Data [J]. AFS Transactions, 2002, 110: 121.

Oldfield W. Quantitative Approach to Casting Solidification. Frazing of Cast Iron [J]. ASM, 1966, 59(2): 945.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by Polish KBN (3T08B04230)

Rights and permissions

About this article

Cite this article

Górny, M. Fluidity and Temperature Profile of Ductile Iron in Thin Sections. J. Iron Steel Res. Int. 19, 52–59 (2012). https://doi.org/10.1016/S1006-706X(12)60139-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(12)60139-3