Abstract

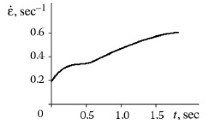

The high temperature deformation behavior of the 9Ni steel has been studied by the Gleeble-3500 tester. The relationship between deformation resistance and deformation degree, deformation temperature and deformation rate was revealed. The results show that when the deformation degree is less than 0.2, the deformation resistance increases by about 70 to 200 MPa, while the deformation degree varied between 0.2 and 0.4, the deformation resistance increases by about 30–40 MPa, when the deformation degree is larger than 0.4, the deformation resistance increases slowly, some become stable gradually. The influence of deformation temperature on deformation resistance is larger, and deformation resistance at higher temperature is about 160 MPa smaller than at lower temperature. Higher deformation rate leads to larger deformation resistance. The deformation resistance increases about 70 to 110 MPa with the increase of the deformation rate. A new and highly accurate mathematical model of the steel was established to describe the deformation behavior during rolling.

Similar content being viewed by others

References

WANG Xiu-li. The State-of-the-Art in Natural Gas Production [J]. Journal of Natural Gas Science and Engineering, 2009(1): 14.

Mario Miana, Rafael del Hoyo, Vega Rodrigálvarez, et al. Calculation Models for Prediction of Liquefied Natural Gas (LNG) Ageing During Ship Transportation [J]. Applied Energy, 2010, 87: 1687.

Nobuo Nakada, Junaidi Syarif, Toshihiro Tsuchigama, et al. Improvement of Strength-Ductility Balance by Copper Addition in 9%Ni Steel [J]. Materials and Science and Engineering, 2004, 374 A: 137.

Zhang L, Takahito Ohmura, Akinobu Shibata, et al. Characterization of Local Deformation Behavior of Fe-Ni Lenticular Martensite by Nanoindentation [J]. Materials Science and Engineering, 2010, 527A: 1869.

Hiromoto Kitahara, Rintaro Ueji, Masato Ueda, et al. Crystal-lographic Analysis of Plate Martensite in Fe-28. 5at%Ni by FE-SEM/EBSD [J]. Materials Characterization, 2005, 54, 378.

Hiromoto Kitahara, Rintaro Ueji, Nobuhiro Tsuji, et al. Crys-tallographic Features of Lath Martensite in Low-Carbon Steel [J]. Acta Materialia, 2006, 54: 1279.

Danil’chenko V E, Sagaradze V V, I ’Heritier Ph. Martensite Crystal Structure of Nickel Steel at Cryogenic Temperatures [J]. Materials Science and Engineering, 2003, 358A: 26.

Emadoddin E, Akbarzadeh A, Daneshi Gh. Effect of Intercriti-cal Annealing on Retained Austenite Characterization in Textured TRIP-Assisted Steel Sheet [J], Materials Characterization, 2006, 57: 408.

ZHAO X Q, Pan T, WANG Q F, et al. Effect of Intercritical Quenching on Reversed Austenite Formation and Cryogenic Toughness in QLT-Processed 9%Ni Steel [J]. Journal of Iron and Steel Research, International, 2007, 14(Supplement 1): 240.

Lee C H, Lee S W, Yoo J Y, et al. Enhancement of Low Temperature Toughness of Nickel Steel by Intercritical Quenching Treatment [C]//Proceedings of the Second Pacific Rim International Conference on Advanced Materials and Processing. Kyongju: [s. n. ], 1995: 2035.

Ahn Yeon-Sang, Kim Hong-Deok, Byun Thak-Sang, et al. Application of Intercritical Heat Treatment to Improve Toughness of SA508C1. 3 Reactor Pressure Vessel Steel [J]. Nuclear Engineering and Design, 1999, 194: 161.

ZHANG Chunling, CAI Dayong, LIAO Bo, et al. A Study on the Dual-Phase Treatment of Weathering Steel 09CuPCrNi [J]. Materials Letters, 2004, 58: 1524.

YANG Jing-hong, LIU Qing-you, SUN Dong-hai, et al. Re-crystallization Behavior of Deformed Austenite in High Strength Microalloyed Pipeline Steel [J]. J Iron Steel Res, Int, 2009, 16(1): 75.

Sun Z Q, Yang W Y, Qi J J, et al. Deformation Enhanced Transformation and Dynamic Recrystallization of Ferrite in a Low Carbon Steel During Multipass Hot Deformation [J]. Mater Sei Eng, 2002, 334A: 201.

Anbuselvan S, Ramanathan S. Hot Deformation and Processing Maps of Extruded ZE41A Magnesium Alloy [J]. Mater Des, 2010, 31: 2319.

Eghbali B, Abdollan-zadeh A. The Influence of Thermome-chanical Parameters in Ferrite Grain Refinement in a Low Carbon Nb-Microalloyed Steel [J]. Scripta Mater, 2005, 53: 41.

Calvo J, Jung I H, Elwazri A M, et al. Influence of the Chemical Composition on Transformation Behavior of Low Carbon Microalloyed Steels [J]. Mater Sei Eng, 2009, 520A: 90.

ZHOU Ji-hua, GUAN Ke-zhi. Plastic Deformation Resistance of Metal [M]. Beijing: Mechanic Industry Publishing Company, 1989 (in Chinese).

CHEN Ping-yan. SPSS 13. 0 Statictical Software Application Tutorials [M], Beijing: People’s Medic Publishing House, 2005.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Key Technology Research and Development Program in 11th Five-Years Plan of China (2006BAE03A06)

Rights and permissions

About this article

Cite this article

Zhang, K., Wu, Hb. & Tang, D. High Temperature Deformation Behavior of Fe-9 Ni-C Alloy. J. Iron Steel Res. Int. 19, 58–62 (2012). https://doi.org/10.1016/S1006-706X(12)60100-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(12)60100-9