Abstract

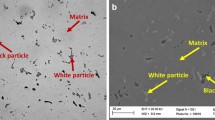

To investigate the wear resistance of ZG42CrMo in industrial application, the wear behaviors under different normal loads, sliding speeds and ambient temperatures were simulated by an MMU-5G abrasion tester to acquire the friction coefficients and wear rates, with the morphology of worn surface observed by scanning electron microscopy (SEM) and chemical composition of worn surface and debris analyzed by X-ray energy dispersive spectroscopy (EDS). Combine with the theory of tribology, finally the regular of environmental factors’ influence on material wear behaviors is determined. The results show that the increase of load decreases wear resistance significantly, when the pressure reaches a certain extent, severe spalling occurs on the worn surface; the changes of speed result in the changes of size of abrasive debris, and then effect the wear behaviors, in the increasing process of speed, the wear rate increases firstly and then decreases; the rise of temperature causes changes in wear mechanism, bring forth oxidation film on the worn surface, which leads to significant improvement of the wear resistance of materials under high temperature compared to that under low temperature.

Similar content being viewed by others

References

LIU Lin, CAI Shu-fang, LIU Li-nan, et al. Quality Control and Heat Treatment of Large ZG42CrMo Cast Steel Gear [J]. Foundry, 2009, 58(7): 733 (in Chinese).

CHEN Xiang, LIN Si-xing. Application of ZG42CrMo on Gear Ring of Action Wheel [J]. Ordnance Material Science and Engineering, 1991 (5): 43 (in Chinese).

YIN Li-meng. Repair of Track Beam of ZG42CrMo [J]. Welding, 2003 (1): 44 (in Chinese).

ZHAO Fang-xin, ZHANG Ying-jie, ZHANG Song, et al. Fatigue Crack Deflection and Formation of Microcracks in Porosity Area of ZG42CrMo [J]. Acta Metallurgica Sinica, 1996, 32(10): 1057 (in Chinese).

WU Wei-qing. Measurement of Initiation Life of Fatigue Crack of 40Cr Steel [J], Chinese Journal of Applied Mechanics, 2003, 20(3): 141 (in Chinese).

WEN Shi-zhu, HUANG Ping. Principles of Tribology [M]. Beijing: Tsinghua University Press, 2008 (in Chinese).

CUI Xiang-hong, SHAN-Jun, YANG Zi-run, et al. Alloying Design for High Wear-Resistant Cast Hot-Forging Die Steels [J]. Journal of Iron and Steel Research, International, 2008, 15(4): 67.

Coronado J J, Sinatora A. Load Effect in Abrasive Wear Mechanism of Cast Iron With Graphite and Cementite [J]. Wear, 2009, 267: 6.

Stott F H, Jordan M P. The Effects of Load and Substrate Hardness on the Development and Maintenance of Wear-Protective Layers During Sliding at Elevated Temperatures [J]. Wear, 2001, 250: 391.

Farias M C M, Souza R M, Sinatora A, et al. The Influence of Applied Load, Sliding Velocity and Martensitic Transformation on the Unlubricated Sliding Wear of Austenitic Stainless Steels [J]. Wear, 2007, 263: 773.

Temel Savaskan, Yasin Alemdag. Effects of Pressure and Sliding Speed on the Friction and Wear Properties of Al-40Zn-3Cu-2Si Alloy: A Comparative Study With SAE 65 Bronze [J]. Materials Science and Engineering, 2008, 496A: 517.

LIU Yan-qiang, HAN Zhong, CONG Hong-tao. Effects of Sliding Velocity and Normal Load on the Tribological Behavior of a Nanocrystalline Al Based Composite [J]. Wear, 2010, 268: 976.

Basavarajappa S, Chandramohan G, Arjun Mahadevan, et al. Influence of Sliding Speed on The Dry Sliding Wear Behaviour and the Subsurface Deformation on Hybrid Metal Matrix Composite [J]. Wear, 2007, 262: 1007.

Wei M X, Wang S Q, Wang L, et al. Effect of Tempering Condition on Wear Resistance in Various Wear Mechanisms of H13 Steel [J]. Tribol Int, 2011, 44: 898.

Wang S Q, Wei M X, Zhao Y T. Effects of the Tribo-Oxide and Matrix on Dry Sliding Wear Characteristics and Mechanisms of a Cast Steel [J]. Wear, 2010, 269: 424.

CUI Xiang-hong, WANG Shu-qi, JIANG Qi-chuan. High-Temperature Wear Mechanism of Cast Hot-Forging Die Steel 4Cr3Mo2NiV [J]. Acta Metallurgica Sinica, 2005, 41(10): 1116 (in Chinese).

Hager C H Jr, Sanders J, Sharma S, et al. The Effect of Temperature on Gross Slip Fretting Wear of Cold-Sprayed Nickel Coatings on Ti6A14V Interfaces [J]. Tribology International, 2009, 42: 491.

JIANG Zhi-qiang, DU Jian-ming, FENG Xi-lan. Study and Application of Heat Treatment of Multi-Element Wear-Resistant Low-Alloy Steel [J]. Journal of Iron and Steel Research, International, 2006, 13(1): 57.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by High Technology Research and Development Program of China (2009AA04Z143); New Century Excellent Talents in University of China (NCET-09-0117)

Rights and permissions

About this article

Cite this article

Zhang, J., Peng, Y., Liu, Hm. et al. Influence of Normal Load, Sliding Speed and Ambient Temperature on Wear Resistance of ZG42CrMo. J. Iron Steel Res. Int. 19, 69–74 (2012). https://doi.org/10.1016/S1006-706X(12)60090-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(12)60090-9