Abstract

CaO−Al2O3−SiO2−CaF2−MgO was selected as the slag system for desulfurization in LF process. The reaction between steel and slag during desulfurization has been simulated by using Factsage software to study the influence of component on the sulfur distribution ratio. In order to research the influence of CaO content, aluminum powder content and its granularity on desulfurization, laboratory experiments have been carried out in a 200 kg inductive furnace. Results showed that the optimal composition of deep desulfurizer is wCaO = 64% and aluminium powder 10% with a granularity of 30 μm. Industrial trials showed that the main composition range of final slag in LF process is wCaO = 53.0%–57.0%, wAl2O3=23.4%–25.1%, wSiO2=8.1%–10.0%, and wCaF2=3.2%–4.7%. The sulfur mass percent in steel is lower than 0.000 8% with a desulfurization rate above 89%. According to the result of industrial production, this desulfurizer could meet the production requirement for ultra-low sulfur steel, of which sulfur mass percent is under 0.0015%.

Similar content being viewed by others

References

Rama B, Dave T. Ladle Slag Treatment for Production of Ultra-Low Carbon Steels [C]//1993 Steelmaking Conference Proceedings. [S. 1.]: Association for Iron and Steel Technology, 1993: 457.

Mauro P. A New Generation of Ultra High Strength X100/ XI20 Pipelines: A Breakthrough for Economic Long-Distance Gas Transportation [C]//The Proceedings of the International Offshore and Polar Engineering Conference. [S. 1.]: International Society of Offshore and Polar Engineers, 2005: 31.

Seune C H, Jae C A, Sang Y N, et al. Mechanical Properties of High-Si Plate Steel Produced by the Quenching and Partitioning Process [J], Metals and Materials International, 2007, 13(6): 439.

YIN Rui-yu, WANG Xin-hua. Discussion on Proper Secondary Refining Methods of Steel Grades for Cold Rolled Sheets [J]. Iron and Steel, 2007, 42(5): 1 (in Chinese).

Kimiaki S. Technology for Production of Austenite Type Clean Stainless Steel [J]. ISIJ International, 2006, 46(12): 1795.

CHEN Song-lin, LV Yan-chun, MA Qing-shen. Application of Sulfur Distribution Ratio in Optimization of LF Ladle Slag Composition [J]. Steelmaking, 2009, 25(3): 37 (in Chinese).

Turkdogan E T. Slags and Fluxes for Ferrous Ladle Metallurgy [J]. Ironmaking and Steelmaking, 1985, 12(2): 64.

ZHANG Cai-jun, CAI Kai-ke, YUAN Wei-xia, et al. Performance Requirements and Productive Feature of Pipeline Steel [J]. Iron and Steel, 2006, 41(8): 31 (in Chinese).

YANG Xiao-jiang, XIA Chun-xue, WANG Xiao-ming, et al. Practice of Accelerated Desulphurization Process for 150 t LF [J]. Steelmaking, 2006, 22(1): 16 (in Chinese).

Jonsson P G. Viscosities of Slags and Their Impact on Ladle Refining [J]. ISIJ International, 1997, 37(5): 484.

LI Liang. Variety Steel Smelting Practice and Refining Effect Analysis in LF Furnace Process [J]. Research on Iron and Steel, 2007, 35(6): 8 (in Chinese).

Sonsinsky D, Sommerville I. The Composition and Temperature Dependence of the Sulfide Capacity of Metallurgical Slags [J]. Metall Trans, 1986, 17B: 331.

Young R, Duffy J, Hassall G, et al. Use of Optical Basicity Concept for Determining Phosphorus and Sulphur Slag-Metal Partitions [J]. Ironmaking and Steelmaking, 1992, 19(3): 201.

Nzotta M M, Du S, Seetharaman S. Sulphide Capacities in Some Multi Component Slags Systems [J]. ISIJ International, 1998, 38(11): 1170.

HAO Ning, WANG Hai-tao. Calculation and Analysis of Sulphide Capacity and Sulphur Partition Ratio [J]. Journal of University of Science and Technology Beijing, 2000, 28(1): 25.

Pelton A D. Thermodynamic Database Development; Modeling and Phase Diagram Calculations in Oxide Systems [J]. Rare Met, 2006, 25(5); 473.

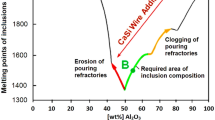

JIN Li-ling, WANG Hai tao, XU Zhong-bo, et al. Control on Low Melting Point Area in a CaO-SKVAlzCVMnG System [J]. Journal of University of Science and Technology Beijing, 2007, 29(6): 574 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Key Technology Research and Development Program in 11th Five-Year Plan of China (2007BAF08B01-03)

Rights and permissions

About this article

Cite this article

Wu, L., Pei, F., Chen, Y. et al. Experimental Study on Deep Desulfurizer in LF Process. J. Iron Steel Res. Int. 19, 17–21 (2012). https://doi.org/10.1016/S1006-706X(12)60081-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(12)60081-8