Abstract

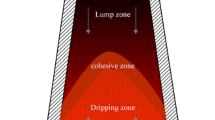

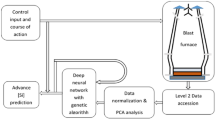

In blast furnace (BF) iron-making process, the hot metal silicon content was usually used to measure the quality of hot metal and to reflect the thermal state of BF. Principal component analysis (PCA) and partial leastsquare (PLS) regression methods were used to predict the hot metal silicon content. Under the conditions of BF relatively stable situation, PC A and PLS regression models of hot metal silicon content utilizing data from Baotou Steel No. 6 BF were established, which provided the accuracy of 88.4% and 89.2%. PLS model used less variables and time than principal component analysis model, and it was simple to calculate. It is shown that the model gives good results and is helpful for practical production.

Similar content being viewed by others

References

LIU Xiang-guan, LIU Fang. Blast Furnace Process Optimization and Intelligent Control Systems [M]. Beijing: Metallurgical Industry Press. 2003 (in Chinese).

WANG Hui-wen. Partial Least-Square Regression Method and Application [M]. Beijing: National Defense Industrial Press. 1999 (in Chinese)

YU Jin-hua. YANG Wei-quan. Multivariate Statistical Analysis and Application [M]. Guangzhan: Guangzhou Zhong-Shan University Press, 2005 (in Chinese).

ZHANG Hong, LIN Yin, LIU Ping. Analysis and Predictions of Real Estate Company Profitability Based on Principle Componential Analyses [J]. Journal of Tsinghua Universityi Science and Technology, 2010, 50(3); 470 (in Chinese).

LI Qi-hui. LIU Xiang-guan. Fuzzy Predictive Functional Control of Silicon Content in Hot Metal [J], Journal of Zhengzhou University: Natural Science Edition, 2007, 39(3); 104 (in Chinese).

ZHANG Chi-bin, SHI Jin-fei, YI Hong. Manufacture Process Quality Modeling Based on Partial Least Square Regression [J]. Journal of Southeast University: Natural Science Edition, 2005, 35(5): 702 (in Chinese).

ZHANG Hong-wei, Barry Lennox. Integrated Condition Monitoring and Control of Fed-Batch Fermentation Processes [J]. Journal of Process Control, 2004 (14), 41.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (51064019); Natural Science Foundation of Inner Mongolia of China (20010MS0911, NJzy08075)

Rights and permissions

About this article

Cite this article

Shi, L., Li, Zl., Yu, T. et al. Model of Hot Metal Silicon Content in Blast Furnace Based on Principal Component Analysis Application and Partial Least Square. J. Iron Steel Res. Int. 18, 13–16 (2011). https://doi.org/10.1016/S1006-706X(12)60015-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(12)60015-6