Abstract

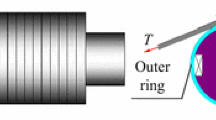

In specific condition, when wrapping angle of cold rolling strip covering surface of shape detecting roll dynamically changes, online radial compression of the shape detecting roll is changed too, and it seriously affects online shape detecting precision of cold strip. Based on the latest intelligent shape meter developed by Yanshan University, using PSO-BP neural network and actual working condition datum, the cold strip online dynamic wrapping angle compensation model is established, and successfully applied in 1 250 mm 6-high cold mill, remarkable results are achieved. The error between calculated values and measured values of total tensions is within 3%.

Similar content being viewed by others

References

LIAN Jia-chuang, LIU Hong-min. Control of Strip Thickness and Shape CM]. Beijing: Enginery Industry Publishing Company, 1996 (in Chinese).

WANG Jun-sheng, BAI Jin-Ian, LIU Xiang-hua. Theory and Process Control of Cold Strip Rolling [M]. Beijing: Science Press, 2009 (in Chinese).

XU Le-jiang. Shape Control and Mill Type Selection of Cold Mill Strip [M]. Beijing: Metallurgical Industry Press, 2007 (in Chinese).

LIN Zhen-bo, DU AN Zhen-yong, LIAN Jia-chuang, et al. Analysis on Shape Standard Curve of Cold Rolling Mill and Its Selection [J]. Journal of Iron and Steel Research, 1997, 9(3): 55 (in Chinese).

BAI Jian, ZHANG Qing-dong, CHANG Tie-zhu, et al. Target Curve Setting Model for Automatic Flatness Control on Stand 1 of 1 420 Cold Tandem Mill [J]. Iron and Steel, 2007, 42(10): 56 (in Chinese).

ZHEN Zhi-gang, LI Xin-wei, CHENG Qi-hua, et al. Improvement of Shape Curve of 1220 5-Stand Cold Tandem Mill [J]. Shanghai Metals, 2008, 30(4): 55 (in Chinese).

LIU Hong-min, DING Kai-rong, LI Xing-dong, et al. Theoretical Computational Method of Shape Standard Curve [J]. Chinese Journal of Mechanical Engineering, 2008, 44(8): 137 (in Chinese).

YU Bing-qiang, YANG Li-po, LIU Hong-min, et al. Development and Industry Application of Contact Shape Meter With New Structure [J]. Chinese Journal of Scientific Instrument, 2010, 31(4): 904 (in Chinese).

YU Bing-qiang, SUN Ya-bo, LIU Hong-min, et al. Compensation Model for Shape Measuring of Cold Strip Rolling [J]. Journal of Iron and Steel Research, International, 2010, 17(6): 21.

LIU Hong-min, YANG Li-po, YU Bing-qiang, et al. Entire Inlayed Block Intelligence Type Shape Meter: China, CN101694368A [P]. 2010-04-07 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Science and Technology Support Plan of China (2007BAF02B10); Natural Science Foundation of Hebei Province of China (E2011203004)

Rights and permissions

About this article

Cite this article

Yang, Lp., Yu, Bq., Yu, Hx. et al. Online Shape Dynamic Wrapping Angle Compensation Model of Cold Strip. J. Iron Steel Res. Int. 18, 28–32 (2011). https://doi.org/10.1016/S1006-706X(11)60086-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(11)60086-1