Abstract

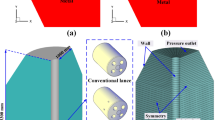

Based on the operating conditions of oxygen lance utilized for a 50 t converter in Tangsteel, gas jet flow fields of three types of oxygen lances were simulated by FLUENT software. The influence of lance configuration and lance level on penetrating area was studied through cold model experiment. The results showed that the gas flow velocities of four-hole, variable angle four-hole and five-hole oxygen lances declined rapidly with an increase in gas jet length within 1 m, 1 m and 0.8 m, respectively. Besides, the multi gas streams sprayed from these three lances should be syncretized at 1.6 m, 1.7 m and 1.4 m, respectively. At the highest lance level, the effective penetrating area of these three lances could be 0.255 m2, 0.385 m2 and 0.090 7 m2, respectively. It was suggested that the effective penetrating area of variable angle four-hole oxygen lance was the biggest, while that of five-hole oxygen lance was the least. The validity of numerical simulation results was proved through cold model experiment. The lance level was suggested to be controlled in the range of 1–1.6 m, 1—1.7m and 0.8–1.4 m for the four-hole, variable angle four-hole and five-hole oxygen lances, respectively.

Similar content being viewed by others

Abbreviations

- C1∈, C2∈, Cμ:

-

Empirical constants

- c P :

-

Specific heat capacity

- G k :

-

Generation scale of turbulence kinetic energy owing to mean velocity gradient

- k:

-

Turbulent energy

- P:

-

Pressure

- S:

-

General source term

- T:

-

Temperature

- t:

-

Time

- u′i:

-

Pulsating velocity

- ui, xi, xj, xk:

-

Index symbols in tensor

- Г:

-

General diffusion coefficient

- ε:

-

Turbulent dissipation rate

- ϕ:

-

General variable

- μ:

-

Heat transfer coefficient of the fluid

- λ:

-

Viscosity coefficient

- μ1:

-

Turbulent viscosity

- ρ:

-

Density

- σk, σte:

-

Turbulent Prandtl numbers for k and e.

References

YIN Zhen-jiang, ZHU Rong, LU Di-wei, et al. Numerical Simulation and Optimization Practice of BOF Lance [J]. Energy for Metallurgical Industry, 2008, 27(5): 13 (in Chinese).

ZENG Ya-nan, LI Jun-guo, HAN Zhi-jie, et al. Experimental Study on Water Model for a 50 t Top and Bottom Combined Blown Converter at Tangsteel [J]. Special Steel, 2010, 31(2): 21 (in Chinese).

WU Wei, WU Zhi-hong, ZOU Zong-shu, et al. Study on Process Parameters of Dephosphorization for 150 t Combined Blown Converter [J]. Steelmaking, 2005, 21(2): 30 (in Chinese).

YUAN Zhang-fu, YANG Xiao-yi, LU Zhi-xing, et al. Jet Behavior and Metallurgical Performance of Innovated Double-Parameter Oxygen Lance in BOF [J]. Journal of Iron and Steel Research, International, 2007, 14(3): 1.

WANG Fu-jun. Computational Fluid Dynamic Analysis [M]. Beijing: Tsinghua University Press, 2004 (in Chinese).

WANG Rui-jin, ZHANG Kai, WANG Gang. The Technical Foundation and Application Examples of Fluent [M]. Beijing: Tsinghua University Press, 2007 (in Chinese).

WU Feng-lin. Some Research Results of Oxygen Lance Efflux [J]. Energy for Metallurgical Industry, 1989, 8(3): 47 (in Chinese).

YANG Zhu-fang, ZHU Rong, LU Di-wei, et al. Simulation and Application of Four Nozzle of Oxygen Lance in 100 t Converter [C] //Chinese Society of Metals. China Iron and Steel Annual Meeting. Beijing: Metallurgical Industry Press, 2007: 110 (in Chinese).

YUAN Zhang-fu, PAN Yi-fang. Oxygen Lance Technology for Steelmaking [M]. Beijing: Metallurgical Industry Press, 2007 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Jg., Zeng, Yn., Wang, Jq. et al. Simulation of Flow Field of Oxygen Lance Gas Jet Utilized for 50 t Converter. J. Iron Steel Res. Int. 18, 11–18 (2011). https://doi.org/10.1016/S1006-706X(11)60043-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(11)60043-5