Abstract

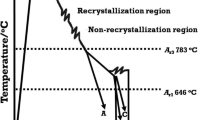

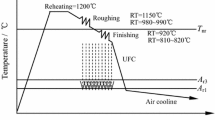

The correlation between microstructures and mechanical properties of a Nb-Ti microalloyed pipeline steel was investigated. The results revealed that with decreasing the finish rolling temperature and the cooling stop temperature, the matrix microstructure was changed from quasi-polygonal ferrite to acicular ferrite, as a result of improvement of both strength and low temperature toughness. By means of electron backscattered diffraction observation, an effective acicular ferrite packet contained several low angle boundaries or subboundaries plates which made important contributions to improvement of strength. It was found that many fine quasi-polygonal ferrite grains with high angle boundaries as the toughening structure were introduced into the acicular ferrite matrix to refine effective grain size and improve the toughness.

Similar content being viewed by others

References

Nagahama, Yamamoto S. High Performance Steel Pipes and Tubes Securing and Exploiting the Future Demands [J]. NKK Tech Rev, 2001, 88: 81.

Shiga, Hatomura, Kudoh J, et al. Development of Large Diameter High Strength Line Pipes for Low Temperature Services [J]. Kawasaki Steel Tech Rep, 1981, 4: 97.

ZHAO Ming-chun, YANG Ke, SHAN Yi-yin. The Effects of Thermo-Mechanical Control Process on Microstructures and Mechanical Properties of a Commercial Pipeline Steel [J]. Mater Sci Eng, 2002, 335A: 14.

Hwang, Kim Y, Lee S. Effective Grain Size and Charpy Impact Properties of High-Toughness X70 Pipeline Steels [J]. Metall Mater Trans, 2005, 36A: 2107.

Kim Y, Kim S, Lim Y, et al. Effect of Microstructure on the Yield Ratio and Low Temperature Toughness of Line-pipe Steels [J]. ISIJ Int, 2002, 42: 1571.

American Petroleum Institute. API Specification 5L-2007 Specification for Line Pipe [S]. Washington: API, 2007.

Krauss, Thompson S W. Ferritic Microstructures in Continuously Cooled Low- and Ultra-Low Carbon Steels [J], ISIJ Int, 1995, 35: 937.

Shanmugam, Misrardk, Hartmann, et al. Microstructure of High Strength Niobium-Containing Pipeline Steel [J]. Mater Sci Eng, 2006, 441A: 215.

Shibata, Asakura K. Transformation Behavior and Micro-structures in Ultra-Low Carbon Steels [J]. ISIJ Int, 1995, 35: 982.

Smith Y, Coldren A, Cryderman R L. Mn-Mo-Nb Acicu-lar Ferrite Steels With High Strength and Toughness [C] // Toward Improved Ductility and Toughness. Tokyo: Climax Molybdenum Company (Japan) Ltd, 1972: 119.

Xiao F, Liao, Shan Y, et al. Challenge of Mechanical Properties of an Acicular Ferrite Pipeline Steel [J]. Mater Sci Eng, 2006, 431 A: 41.

Wang, Yan, Yang K. Relation Among Rolling Parameters, Microstructures and Mechanical Properties in an Acicular Ferrite Pipeline Steel [J]. Mater and Design, 2009, 30: 3436.

Gourgues A, Flower H, Lindler T C. Electron Backsca-ttering Diffraction Study of Acicular Ferrite, Bainite, and Martensite Steel Microstructure [J]. Mater Sci Tech, 2000, 16: 26.

Fuentes M, Mendia A, Gutierrez I. Analysis of Different Acicular Ferrite Microstructures in Low-Carbon Steels by Electron Backscattered Diffraction. Study of Their Toughness Behavior [J]. Metall Mater Trans, 2003, 34A: 2505.

Kim Y, Lee, Kim N J. Transformation Behavior and Microstructure Characteristics of Acicular Ferrite in Linepipe Steels [J]. Mater Sci Eng, 2008, 478: 361.

Mabuchi, Uemori, Fujioka M. The Role of Mn Depletion in Intra-Granular Ferrite Transformation in the Heat Affected Zone of Welded Joints With Large Heat Input in Structural Steels [J]. ISIJ Int, 1996, 36: 1406.

Honeycombe R W, Pickering F B. Ferrite and Bainite in Alloy Steels [J]. Metal Trans, 1972, 3A: 1099.

Edmonds D, Cochrane R C. Structure-Property Relationships in Bainitic Steels [J]. Metell Trans, 1990, 21A: 1527.

Nohava, Hausild, Karlik M. Electron Backscattering Diffraction Analysis of Secondary Cleavage Cracks in a Reactor Pressure Vessel Steel [J]. Mater Character, 2003, 49: 211.

WANG Wei, SHAN Yi-yin, YANG Ke. Study of High Strength Pipeline Steels With Different Microstructures [J]. Mater Sci Eng, 2009, 502A: 38.

Gianetto J, Braid J E, Bowker J, et al. Heat-Affected Zone Toughness of a TMCP Steel Designed for Low-Temperature Applications [J]. ASME, 1997, 119. 134.

Kim Y, Shin S, Lee, et al. Effects of Molybdenum and Vanadium Addition on Tensile and Charpy Impact Properties of API X70 Linepipe Steels [J]. Metall Mater Trans, 2007, 38A: 1731.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (51074052); Fundamental Research Funds for Central Universities of China (N100607001)

Rights and permissions

About this article

Cite this article

Lan, Ly., Qiu, Cl., Zhao, Dw. et al. Microstructural Evolution and Mechanical Properties of Nb-Ti Microalloyed Pipeline Steel. J. Iron Steel Res. Int. 18, 57–63 (2011). https://doi.org/10.1016/S1006-706X(11)60024-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(11)60024-1