Abstract

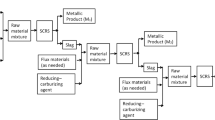

Total ilmenite from Yunnan, p]China, difficult to smelt in blast furnace, was smelted by oxygen-enriched top-blown smelting reduction ironmaking technology. Much more details on smelting were discussed. Specifically, the influence of reduction temperature, slag basicity and molar ratio of carbon to oxygen on the reduction quality level including iron recovery and titanium and sulfur contents in the pig iron produced in the experiment was investigated. Iron recovery rate could reach 95% with titanium content below 0. 05% in pig iron produced, under the conditions of holding time of 30 min at 1 823 K, basicity of 1. 1, carbon to oxygen molar ratio of 1. 0 and oxygen-enriched flow rate of 250 L/h. Oxidization potential of top-space of smelting reduction vessel and slag combination could create the driving force to partition phosphorous, titanium and silicon into the slag, which ensured low contents of the impurities involved above and carbon in pig iron. In addition, it avoided the generation of Ti(C,N) that could reduce interfacial tension of slag, which induced the formation of foaming slag seriously. Furthermore, jam of chargings and bubble flooding would be triggered, resulting in deterioration of BF state, increase of iron loss and decline of desulfurization rate.

Similar content being viewed by others

References

XUE Bu-gao. Yunnan Ilmenite Geological Characteristics and Discussion of Development [J], Chemical Geology for Mineral Resources, 2001, 23(1): 53.(in Chinese).

ZHOU Chuan-dian. Experimental Research on Smelting V-Ti Magnetite [J]. Angang Technology, 2004, (2): 1.(in Chinese).

DENG Guo-zhu. Research on the Use of Ilmenite Resources in Yunnan [J]. Development of Titanium Industry, 1999, (3): 30.(in Chinese).

Brotzmann K. New Concepts and Methods for the Iron and Steel Production [J]. Neue Hutte, 1988, 33(12): 441.

Goldsworthy T, Dry R, Bates C, et al. HIsmelt—The Alternative Technology for Ironmaking [J]. SEAISI Quarterly (South East Asia Iron and Steel Institute), 2000, 29(2): 43.

Feinman J. Direct Reduction and Smelting Processes [J]. Iron and Steel Engineer, 1999, 76(6): 75.

DU He-gui. Principles of Smelting Vanadium-Titanium Magnetite by Blast Furnace [M], Beijing: Science Press, 1996 (in Chinese).

DU He-gui, DU Gang. Restrain the Generation of Ti(CN) by FeO in High-Titania Slag [C] // MA Jia-yuan. Theory and Practice on Smelting Vanadium-Titanium Magnetite by Blast Furnace. Beijing: Metallurgical Industry Press, 2000: 66.(in Chinese).

HUANG Xi-hu. Principles of Iron and Steel Metallurgy [M]. 3rd ed. Beijing: Metallurgical Industry Press, 2006 (in Chinese).

YANG Xiao-yuan. Research on Jam of Chargings and Bubble Flooding of High-Titania Slag in Blast Furnace [J]. Journal of Kunming University of Science and Technology, 1999, 24 (4): 112.(in Chinese).

FAN Ru-hai, REN Hong-shan, HU Sheng-zhong. Practice on Smelting Vanadium-Titanium Magnetite in Pangang [J]. Sichuan Metallurgy, 2005, 27(5): 21.(in Chinese).

PAN Qun. Analysis of Effect of Iron Loss on Smelting Vanadium-Titanium Magnetite [J]. Sichuan Metallurgy, 2005, 27 (6): 17.(in Chinese).

Theodore Leczo. HIsmelt® Technology: The Future of Iron-making [J]. Iron and Steel Technology, 2009, 6(3): 33.

Brotzmann, Karl. Simlling Reduction in Iron Baths [J]. Steel Research, 1989, 60(3): 110.

Anon. Rio Tinto Gives HIsmelt Thumbs Up [J]. Engineering and Mining Journal, 2002, 203(6): 4.

Burke P, Gull S. HIsmelt—The Alternative Ironmaking Technology [EB/OL]. [2009-12-20]. https://doi.org/www.hismelt.com/EN/Documents/TechnicalPapers/2002_12_bhubaneswar_burke_guil.pdf.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by Provincial Natural Science Foundation of Yunnan Province of China (2009ZC014M)

Rights and permissions

About this article

Cite this article

Li, Hb., Wang, H., Qi, Yl. et al. Ilmenite Smelted by Oxygen-Enriched Top-Blown Smelting Reduction. J. Iron Steel Res. Int. 18, 7–13 (2011). https://doi.org/10.1016/S1006-706X(11)60016-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(11)60016-2