Abstract

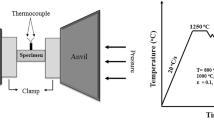

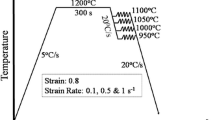

Through the expansion curve of continuous cooling transformation at different cooling rates measured by THERMECMASTOR-Z thermal simulator for U75V rail steel, the continuous cooling transformation curve was obtained. The influence on steel microstructure and hardness at different cooling rates was studied. The softening behavior of isothermal deforming in austenite area of 850—1000 °C in the interval of passes was also studied by double-pass compression test. The results show that the product of austenite transformation is pearlite when the cooling rate is lower than 10 °C. When the cooling rate was in the range of 10 — 50 °C • s−1, only martensite was received. The hardness of the test steel increases with increasing the cooling rate. Under the condition of deformation of 30% and deformation rate of 3 s−1, the relaxation time for complete recrystallization was shorter than 100 s when deformation temperature was higher than 1000 °C. When deformation temperature was lower than 880 °C, complete recrystallization of steel was difficult to achieve even if the relaxation time is extended.

Similar content being viewed by others

References

ZHOU Zhen-guo. Structure Parameter to Performance Influence on Heat Treatment Rail [J]. Heat Treatment of Overseas Metal, 1999(3): 13 (in Chinese).

XU Quan, MEI Dong-sheng, YU Meng-wen. Effect of Vanadium in Rail Steel [J]. Iron and Steel, 2001, 36(6): 44 (in Chinese) .

ZHOU Qing-yue, ZHANG Yin-hua, YANG Lai-shun, et al. Material Performance and Correlation Process on Rail [M]. Beijing: China Railway Publishing House, 2005 (in Chinese).

CHEN Zhao-yang. Characteristics of Continuous Cooling of UIC900A and U75V Rail Steel for Welding [J]. China Railway Science, 2005, 26(6): 63 (in Chinese).

Palmiere E J, Garcia Ci, Deardo A J. The Influence of Niobium Supersaturation in Austenite on the Static Recrystallization Behavior of Low Carbon Microalloyed Steels [J]. Metall Mater Trans, 1996, 27A: 951.

Kliber J, Schindler I. Recrystallization Precipitation Behavior in Microalloyed Steel [J]. Materials Processing Technology, 1996, 60: 597.

Medina S F. The Influence of Niobium on the Static Recrystallization of Hot Deformation Austenite and Strain Induced Precipitation Kinetics [J]. Metallurgical et Materialia, 1995, 32 (1): 43.

Medina S F, Mancilla J E. Determination of Static Recrystallization Critical Temperature of Austenite in Microalloyed Steels [J]. ISIJ Inter, 1993, 33(12): 1257.

Eghbail B, Abdollah-Zadeh A. The Influence of Thermomechanical Parameters in Ferrite Grain Refinement in a Low Carbon Nb-Microalloyed Steel [J]. Scripta Meterialia, 2005(7): 41.

Cho Sang-hgun, Kang Ki-bong, Jonas John J. The Dynamic, Static and Metadynamic Recrystallization of a Nb-Microalloyed Steel [J]. ISIJ International, 2001, 41(1): 63.

Fermndez A I, Lopez B, Rodriguez Ibabe J M. Relationship Between the Austenite Recrystallization Fraction and the Softening Measured From the Interrupted Torsion Test Technique [J]. Script Materialia, 1999, 40(5): 543.

Bai D Q, Yue S, Sun W P, et al. Effect of Deformation Parameters on the Non-Recrystallization Temperature in Nb-Bearing Steels [J]. Metallurgical Transaction, 1993, 24A: 2151.

Gomez M, Medina S F, Quispe A, et al. Static Recrystallization and Induced Precipitation in a Low Nb Microalloyed Steel [J]. ISIJ International, 2002, 42(4): 423.

Bakkaloglu Adem. Effect of Processing Parameters on the Microstructure and Properties of an Nb Microalloyed Steel [J]. Materials Letters, 2002, 56: 200.

Pentti Karjalanen L, Maccagno Temence M, Jonas John J. Softening and Flow Strain Behavior of Nb Microalloyed Steel During Hot Rolling Simulation [J]. ISIJ International, 1995, 35(12): 1523.

Palmiere E J, Garcia Ci, Deardo A J. Compositional and Microstructure Changes Which Attend Reheating and Grain Coarsening in Steels Containing Niobium [J]. Metall Material Trans, 1994, 25A: 277.

Chiaki Ouchi. Development of Steel Plates by Intensive Use of TMCP and Direct Quenching Process [J]. ISIJ International, 2001, 41(6): 542.

Dutta B, Palmiere E J, Sellars C M. Modelling the Kinetics of Strain Induced Precipitation in Nb Microalloyed Steels [J]. Acta Material, 2001, 49(5): 785.

Dutta B, Valdes E, Sellars C M. Mechanism and Kinetics of Strain Induced Precipitation of Nb(C, N) in Austenite [J]. Acta Metall Meterial, 1992, 40(4): 653.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ren, Ac., Ji, Y., Zhou, Gf. et al. Hot Deformation Behavior of V-Microalloyed Steel. J. Iron Steel Res. Int. 17, 55–60 (2010). https://doi.org/10.1016/S1006-706X(10)60129-X

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(10)60129-X