Abstract

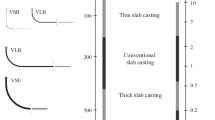

In order to check the general existence of broadening of slab and the reasons of formation, the broadening of slab was investigated on the basis of several industrial manufactures of continuous casting. The results show that slab broadening commonly exists in the process of continuous casting. The causes of broadening were ruled out of the consideration of the change of mold size or the change of technical parameters. The results reveal that the broadening of slab probably results from the static pressure of molten steel and the force from driving rolls. At the same time, online observations of three grades of steel in the process of continuous casting reveal that the ratio of ultimate broadening of slab ranges from 1.27% to 3.00%, and even arrives at 4.4%.

Similar content being viewed by others

References

Fujii H, Ohashi T, Hiromoto T. On the Formation of Internal Cracks in Continuously Cast Slabs [J]. Transactions of the Iron and Steel Institute of Japan, 1978, 18: 510.

Miyazawa K, Schwerdtfeger K. Computation of Bulging of Continuously Cast Slab With Simple Bending Theory [J]. Ironmaking and Steelmaking, 1979(2): 68.

Royzman S E. Shrinking Stresses in a Solidifying Continuous Slab [J]. Steel Technology International, 1994(5): 123.

Siyasiya C, Rooyen G T, Stumpf W E. Metallurgical Factors That Affect the Strand Width During Continuous Casting of DIN 1.4003 Stainless Steel [J]. Journal of the South African Institute of Mining and Metallurgy, 2005(105): 473.

CUI Li-xin, ZHANG Jia-quan, CHEN Zhi-ping, et al. Crack of Continuous Casting Slab [J]. Iron and Steel, 2004, 39(supplement): 706 (in Chinese).

XIONG Yi-gang. Continuous Casting of Slab [M]. Beijing: Metallurgical Industry Press, 1994 (in Chinese).

Matsumiya T. Recent Topics of Research and Development in Continuous Casting [J]. ISIJ International, 2006, 46(12): 1800.

Mizukami H, Murakami K, Miyashita Y. Mechanical Properties of Continuously Cast Steel at High Temperatures [J]. Tetsu-to-Hagane, 1977, 63: 146 (in Japanese).

Uehara M, Samarasekera I V, Brimacombe J K. Mathematical Modeling of Unbending of Continuously Cast Steel Slabs [J]. Ironmaking and Steelmaking, 1986(12): 138.

Ramacciotti A. Thermo-Mechanical Behavior of the Solidified Shell in a Funnel-Shaped Mold for Continuous Casting of Thin Slabs [J]. Steel Research, 1988, 59: 438.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Science and Technology Support Program for 11th Five-Year Plan of China (2006BAE03A04)

Rights and permissions

About this article

Cite this article

Fu, Jx., Li, Js., Zhang, H. et al. Industrial Research on Broadening of Slab in Continuous Casting Process. J. Iron Steel Res. Int. 17, 20–24 (2010). https://doi.org/10.1016/S1006-706X(10)60122-7

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(10)60122-7