Abstract

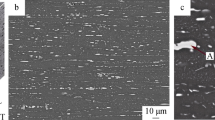

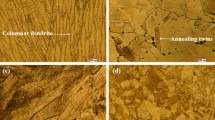

The microstructure of hot rolled AEREX350 alloy under various solution treatments was investigated by scanning electron microscope (SEM) and transmission electron microscope (TEM). It was found that with increasing solution temperature, η phase precipitated firstly at grain boundaries in parallel at 800 °C and then within grains at about 980 °C. The η phase precipitated at grain boundaries played a role in preventing the migration of grain boundaries, and the η phase precipitated within grains would form Widmannstätten structure with further increasing solution temperature η phase precipitated at grain boundaries was dissolved at temperature ranging from 1080 °C to 1095 °C, resulting in grain growth promptly owing to release of the pinning effect on grain boundaries. γ′ phase precipitated during the process of air cooling after hot rolling and dissolved at temperature ranging between 1010 °C and 1 020 °C.

Similar content being viewed by others

References

SPS Technologies Aerospace Fasteners Group. Superalloys Developed by SPS Technologies for Aerospace Fasteners [R]. Jenkintown: SPS Technologies Inc, 1998.

Buzolits S. New High Temperature Alloy Characterized by Superior Alloy Properties at Temperatures to 1 350 °F [J]. Industrial Heating, 1994, 61(12): 34.

Buzolits S R, Kline L A. Bolting Alloy Fills High Temperature Gap [J]. Advanced Materials and Processes, 1995, 147(2): 33.

ASM International. Nickel Alloy [J]. Alloy Digest, 1995(5): Ni-479.

Asgari S. Age-Hardening Behavior and Phase Identification in Solution-Treated AEREX350 Superalloy [J]. Metall Mater Trans, 2006, 37A(7): 2051.

Tomasello C M, Pettit F S, Birks N, et al. Precipitation Behavior in AEREX350 [C] //Kissinger R D, Deye D J, Anton D L, et al. Superalloys 1996. Warrendale: TMS, 1996: 145.

Shibata T, Shudo Y, Takahashi T, et al. Effect of Stabilizing Treatment on Precipitation Behavior of Alloy 706 [C] //Kissinger R D, Deye D J, Anton D L, et al. Superalloys 1996. Warrendale: TMS, 1996: 627.

Danflou H L, Marty M, Walder A. Formation of Serrated Grain Boundaries and Their Effect on the Mechanical Properties in a P/M Nickel Base Superalloy [C] // Antolovich S D, Stusrud R W, Mackay R A, et al. Superalloys 1992. Warrendale: The Minerals, Metals and Materials Society, 1992: 63.

Samiee M, Asgari S. Influence of Solution Treatment on Precipitation Behavior of a Ni-Co Alloy [J]. Scripta Materialia, 2007, 57(2): 93.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wan, Wj., Han, Gw. & Deng, B. Influence of solution treatment on microstructure of AEREX350 alloy. J. Iron Steel Res. Int. 17, 67–71 (2010). https://doi.org/10.1016/S1006-706X(10)60075-1

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(10)60075-1