Abstract

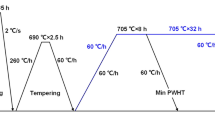

The ultra-fast cooling technology of large section bars and the microstructure for different cooling patterns were studied by optical microscope, transmission electron microscope and energy spectrometer. The results indicated that the large section bars were passed through the zone of secondary carbide precipitation quickly by ultra-fast cooling technology (UFC) at instantaneous cooling rate of about 200 °C/s and the finishing cooling temperature was higher than Ms. The lamellar spacing of pearlite decreased and the microhardness increased with decreasing the rereddening temperature. The precipitation of network carbide was restrained when re-reddening temperature was 690 °C. And fine laminated pearlite was obtained through transformation of pseudopearlition that induced the reduction of the diameter of pearlite grain and refinement of the lamellar spacing of pearlite, so ideal microstructures of promoting spheroidizing annealing were obtained.

Similar content being viewed by others

References

Seto Kouzou. Bearing Steel-Born and Evolved in the 20th Century [M]. CHEN Hong-zhen, trans. Beijing: Metallurgical Industry Publisher, 2003 (in Chinese).

Lund T. Akesson J. Oxygen Content, Oxidic Micro-Inclusion and Fatigue Properties of Rolling Bearing Steel, Effect of Steel Manufacturing Processes on the Quality of Bearing Steel [J]. 1998, ASTM STP, 1327-EB: 308.

ZHANG Jing-Guo. Microstructure and Continuous Cooling Transformation Thermograms of Spray Formed GCr15 Steel [J]. Material Science and Engineering, 2002, 326A: 20.

Han Heung Nam, Lee Hae Kon, Kim Hong Joon. A Model for Deformation Temperature and Phase Transformation Behavior of Steels on Run-Out Table in Hot Strip Mill [J]. Journal of Materials Processing Technology. 2002, 128(1–3): 216.

Kang M K. The Time-Temperature-Transformation Diagram in Some Alloy Steels [J]. Metallurgical Transactions, Metal Trans, 1992, 25A: 785.

YU Ming-quan. Development and Application of Billet Casting Technology for Bearing Steel [J]. Shanghai Steel Research, 2005, (3): 3 (in Chinese).

ZHANG Jian-guo, XU Han-bing, WU Jian-sheng, et al. A Comparative Study of Spray Formed and Conventionally Processed Cr12MoV Steel for Roll Manufacture [A]. Proceedings of the Fourth International Conference on Spray Forming [C]. Altimore: September 13–15, 1999 (in CD).

Iris V R, Clayton O R. Deviation of Residual Stress Patterns in 52100 Bearing Steel by Inherent Microstructural Transformations After Rolling Contact [J]. Materials Characterization, 2001, 53(8): 381.

LI Sheng-li, XU Jian-zhong, WANG Guo-dong. Simulation and Analysis of Large Cross-Section Bearing Steel TMCP Process [J]. Journal of Northeastern University (Natural Science), 2006, (27): 659 (in Chinese).

Al Jia-he, GAO Hui-ju, XIE Xi-san, et al. Effect of Controlled Rolling and Cooling on the Microstructure and Mechanical Properties of 60Si2MnA Spring Steel Rod [J]. Journal of Materials Processing Technology, 2005, (160): 390.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (50334010)

Rights and permissions

About this article

Cite this article

Sun, Yk., Wu, D. Effect of ultra-fast cooling on microstructure of large section bars of bearing steel. J. Iron Steel Res. Int. 16, 61–65 (2009). https://doi.org/10.1016/S1006-706X(10)60012-X

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(10)60012-X