Abstract

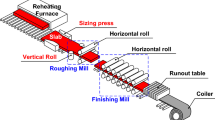

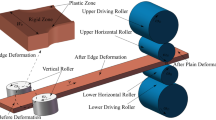

Using 3D rigid-plastic finite element method (FEM), a numerical simulation model for nonsteady state vertical-horizontal rolling process in roughing trains was built and was validated by comparing the simulated values with experimental ones of width and shape of the stock ends. According to certain 2050 roughing processing technologies, the short shape control (SSC) of the stock ends was investigated using the model. Based on the simulated results, a new SSC model was developed. The analyzed results showed that the new SSC model is effective in improving the shape of the stock ends.

Similar content being viewed by others

References

WANG Zhao-dong, WANG Guo-dong, ZHANG Qiang, et al. Technique of Hot Rolled Strip Width Adjustment and Control [J]. Research on Iron and Steel, 1992, (6): 48 (in Chinese).

Fassel A, Liegeon E, Siener P, et al. Reduction of Crop-Losses by Optimal Setting of the Roughing Stands in a Hot Strip Mill [A]. Proceedings of the Mineral Waste Utilization Symposium [C]. Tokyo: Iron and Steel Inst of Jpn, 1980. 252.

FU Jiang, ZHAO Yi-xiang, HE Yu-xin. Simulation Study on Large Width Reduction Process of Slab [J]. Baosteel Technology, 1993, 41(2): 44 (in Chinese).

HAN Li. Industrial Experiments on Edging Rolling on Roughing Trains of the China Built 1700 mm Hot Strip Mill [J]. Iron and Steel, 1999, 34(4): 24 (in Chinese).

Huismann R L. Large Width Reductions in a Hot Strip Mill [R]. Luxembourg: Commision of the European Communities, 1983.

Okado M, Arizumi T, Noma Y. et al. Width Behaviour of the Head and Tail of Slabs at Edge Rolling in Hot Strip Mills [J]. J Iron Steel Inst Jpn, 1981, 67(15): 2516 (in Japanese).

Nikaido H, Naoi T, Shibata K, et al. FEM Simulation of Non-Steady Deformation in Edge Rolling [J]. J Jpn Soc Technol Plas, 1983, 24(268): 486 (in Japanese).

Chung W K, Choi S K, Thomson P F. Three-Dimensional Simulation of the Edge Rolling Process by the Explicit Finite-Element Method [J]. J Mater Process Technol, 1993, 38(1–2): 85.

Gratacos P, Coupu J. 3D Finite Element Code Application in Hot Rolling [J]. Rev Metall Cah Inform Tech, 1994, 91(11): 1671 (in French).

XIONG Shang-wu, LIU Xiang-hua, WANG Guo-dong. Analysis of Non-Steady State Slab Edging in Roughing Trains by a Three-Dimensional Rigid-Plastic Finite Element Method [J]. International Journal of Machine Tools and Manufacture, 2000, 40(11): 1573.

XIONG Shang-wu, LIU Xiang-hua, WANG Guo-dong, et al. A Three-Dimensional Finite Element Simulation of the Vertical-Horizontal Rolling Process in the Width Reduction of Slab [J]. J Mater Process Technol, 2000, 101(1–3): 146.

XIONG Shang-wu, LIU Xiang-hua, WANG Guo-dong, et al. Simulation of Slab Edging by the 3-D Rigid-Plastic FEM [J]. J Mater Proc Technol, 1997, 69(1–3): 37.

Xiong S, Liu X, Wang G, et al. Simulation of Vertical-Horizontal Rolling Process During Width Reduction by Full Three-Dimensional Rigid-Plastic Finite Element Method [J]. J Mater Eng Perform, 1997, 6(6): 757.

LI Xue-tong, XU Shi-min, DU Feng-shan, et al. Study on Strip Tail Shape and Control on Hot Mill [J]. China Mechanical Engineering. 2004, 15(14): 1287 (in Chinese).

Kobayashi S, Oh S, Altan T. Metal Forming and the Finite Element Method [M]. Oxford: Oxford University Press, 1989.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (50534020); National Key Technology Research and Development Program of China (2007BAF02B00); Provincial Natural Science Foundation of Hebei of China (E2008000809)

Rights and permissions

About this article

Cite this article

Zang, Xl., Li, Xt. & Du, Fs. Head and tail shape control in vertical-horizontal rolling process by FEM. J. Iron Steel Res. Int. 16, 35–42 (2009). https://doi.org/10.1016/S1006-706X(10)60008-8

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(10)60008-8