Abstract

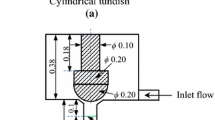

A conventional turbulence inhibitor is compared with a swirling chamber from the points of view of fluid flow and removal rate of inclusion in the tundish. Comparing the RTD curves, inclusion removals, and the streamlines in water model experiments, it can be found that the tundish equipped with a swirling chamber has a great effect on improving the flow field, and the floatation rate of inclusion is higher than the tundish with a turbulence inhibitor. Because of the introduction of the swirling chamber, the flow field and inclusion removal in a two-strand swirling flow tundish are asymmetrical. Rotating the inlet direction of swirling chamber 60 degree is a good strategy to improve the asymmetrical flow field.

Similar content being viewed by others

References

ZHANG Li-feng, Auki J, Thomas B G. Inclusion Removal by Bubble Flotation in a Continuous Casting Mold [J]. Metallurgical and Materials Transactions, 2006, 37B: 361.

Banderas R A, Morales R D, Barreto J De J, et al. Modelling Study of Inclusions Removal by Bubble Flotation in the Tundish [J]. Steel Research, 2006, 77(5): 325.

ZHONG Liang-cai, LI Bao-kuan, ZHU Ying-xiong, et al. Fluid Flow in a Four-Strand Bloom Continuous Casting Tundish With Different Flow Modifiers [J]. ISIJ International, 2007, 47(1): 88.

LIU Jin-gang, YAN Hui-cheng, LIU Liu, et al. Water Modeling of Optimizing Tunsish Flow Field [J]. Journal of Iron and Steel Reseach, International, 2007, 14(3): 13.

Solorio-diaz G. Morales R D. Effect of a Swirling Ladle Shroud on Fluid Flow and Mass Transfer in a Water Model of a Tundish [J]. International Journal of Heat and Mass Transfer, 2005, 48: 3574.

Mazumdar D, Guthrie R I L. The Physical and Mathematical Modeling of Continuous Casting Tundish Systems [J]. ISIJ International, 1999, 39(6): 524.

Miki Y, Ogura S, Fujii T. Separation of Inclusions From Molten Steel in a Tundish by Use of a Rotating Electromagnetic Field [J]. Kawasaki Steel Technical Report (Japan), 1996, 35: 67.

ZOU Zong-shu, HOU Qin-fu, KUANG Shi-bo, et al. Feasibility Study of a Swirling Flow Tundish [A]. Metallurgical Research Institute AB of MEFOS, eds. The 2nd International Conference on Process Development in Iron and Steelmaking [C]. Lulea: Metallurgical Research Institute AB of MEFOS, 2004. 143.

Sahai Y, Emi T. Criteria for Water Modeling of Melt Flow and Inclusion Removal in Continuous Casting Tundishes [J]. ISIJ International, 1996, 36(9): 1166.

Zheng X F, Peter C, HAYIS, et al. Particle Removal From Liquid Phase Using Fine Gas Bubbles [J]. ISIJ International, 1997, 37(11): 1091.

YAN Xiao-ci, LUO Ming-dao. Interface Chemistry [M]. Beijing: Chemical Industry Press, 2005 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yue, Q., Zou, Zs., Hou, Qf. et al. Water modeling of swirling flow tundish for steel continuous casting. J. Iron Steel Res. Int. 16, 17–22 (2009). https://doi.org/10.1016/S1006-706X(10)60004-0

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(10)60004-0