Abstract

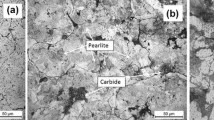

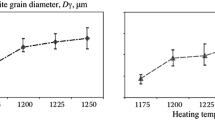

Cold upsetting experiments were carried out on sintered Fe-0.8%C-1.0%Si-0.4%Cu steel preforms in order to evaluate their deformation characteristics. Powder preforms of 86% of theoretical density, with two different ratios of height to diameter, were prepared using a suitable die set assembly on a 1.0 MN capacity hydraulic testing machine. Sintering was carried out in an electric muffle furnace for 1.5 h at 1 150 °C. Each sintered compact was subjected to incremental loading of 0.04 MN under dry friction condition till a crack appeared at the free surfaces. The experimental results were critically analysed, the stress as a function of strain and densification was obtained, then the work hardening behaviour was analyzed. It has been found that in the process of enhancing densification, strength and strain hardening is also induced during upsetting, but the work hardening behaviour is not homogenously enhanced against strain and densification.

Similar content being viewed by others

References

Ryuichiro Goto. Powder Metallurgy Growth in the Automotive Market. Business Briefing: Global Automotive Manufacturing and Technology. Materials, London, 2003: 44.

Kurt H Miska. Introduction to Powder Metallurgy [M]. Samuel Bradbury, eds. Metals Park: ASM, 1979.

Gull G W. Mechanical and Metallurgical Properties of Powder Forgings [J]. Powder Metall, 1970, 13(26): 156.

Lee P W. Powder Metallurgy Applications, Advantages and Limitations [M]. Klar E, eds. Metals Park: ASM, 1983.

German R M. Powder Metallurgy of Iron and Steel [M]. New York: John Wiley and Sons Inc, 1998.

Kuhn H A, Downey C L. How Flow Fracture Affect Design of Preforms for Powder Forging [J]. Int J of Powder Metall and Powder Technol, 1974, 10(1): 59.

Tewari H N, Saran R. Analysis of Iron Powder Forging [J]. Trans of P MA I, 1985, 12: 83.

Jha A K, Kumar S. Forging of Metal Powder Preforms [J]. Int J Mach Tool Des Res, 1983, 23(4): 201.

Hausner H H, Mal M K. Hand Book of Powder Metallurgy [M]. 2nd ed. New york: Chemical Press, 1982.

Pandey K S. Some Investigation on the Cold Deformation Behaviour of Sintered Aluminium —4% Copper Alloy Powder Preforms [J]. Quart Int J Powder Met Sci Technol, 1991, 2 (4): 35.

Lawley A. Advances in Powder Technology [A]. Chin G Y, eds. ASM Materials Science Seminar [C]. Metals Park: ASM, 1982. 75.

Hansen N. Dispersion Strengthened Aluminium Products Manufactured by Powder Blending [J]. Powder Metall, 1969, 12(23): 23.

Antes H W. Processing and Properties of Powder Forgings [A]. Burke J J, Weiss V, eds. Powder Metallurgy for High Performance Applications [C]. Syracuse: Syracuse University Press, 1972. 171.

Kahlow K J. Void Behaviour as Influenced by Pressure and Plastic Deformation [R]. Bethlehem; Institute for Metal Forming Report, Lehigh University, 1971.

Pandey K S. Indigenous Ceramic Coating [D]. Tiruchirappalli: Regional Engineering College, 1983.

Moyer K H. Measuring Density of P/M Materials With Improved Precision [J]. Int J of Powder Met and Powder Technol, 1979, 15: 33.

Rajeshkannan A, Pandey K S, Shanmugam S. Influence of Frictional Constraints Between the Combined Stresses and the Continued Deformation and Densification of Sintered High Carbon P/M Steel During Cold Deformation [A]. Association for Iron and Steel Technology, eds. Proceedings of Green Engineering Materials Processing of International Conference in Materials Science and Technology 2006 [C]. Cincinnati: Association for Iron and Steel Technology. 2006. 105.

Whang B B, Kobayashi S. Deformation Characterization of Powdered Compacts in Compaction [J]. Int J Mach Tools Manuf, 1990, 30(2): 309.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rajeshkannan, A., Pandey, K.S., Shanmugam, S. et al. Sintered Fe-0.8%C-1. 0%Si-0.4%Cu P/M steel preform behaviour during cold upsetting. J. Iron Steel Res. Int. 15, 81–87 (2008). https://doi.org/10.1016/S1006-706X(08)60254-X

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(08)60254-X