Abstract

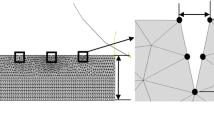

Behavior of transversal crack notched on slab corner during vertical-horizontal rolling process was simulated by FEM. The crack tip stress in the whole rolling process was obtained. Influences of the friction coefficient, the initial crack size, the edger roll profile, and the groove fillet radii of grooved edger roll on crack tip stress were analyzed. For vertical rolling, the tension stress appears at crack tip near the slab top surface and the compression stress appears at crack tip near the slab side surface for the flat edger roll; however, the compression stress appears at crack tip near the slab top surface and the tension stress appears at crack tip near the slab side surface in the exit stage for the grooved edger roll. For horizontal rolling, the tension stress appears at crack tip just at the exit stage for the flat edger roll, and the tension stress appears in whole rolling stage; the tension stress value near the slab side surface is much larger than that near the slab top surface for the grooved edger roll.

Similar content being viewed by others

Abbreviations

- A, B, C, D, F:

-

Constant

- d r :

-

Roll diameter

- f:

-

Friction coefficient

- h:

-

Slab exit thickness

- hx:

-

Slab thickness at x position

- Δh:

-

Slab draft

- K:

-

Mean deformation resistance

- l:

-

Contact arc length

- P x :

-

Rolling pressure

- S h :

-

Forward slip

- T:

-

Temperature

- ε:

-

True strain

- ε̇:

-

True strain rate

- σ:

-

Yield stress

- γ:

-

Neutral angle

References

Nikaido H, Naoi T, Shibata K, et al. Numerical Simulation of Width Spread of Dog-Bone Slab in Non-Steady Horizontal Rolling [J]. J Jpn Soc Technol Plasticity, 1984, 25(277): 129.

XIONG Shang-wu, LIU Xiang-hua, WANG Guo-dong, et al. A Three-Dimensional Finite Element Simulation of the Vertical-Horizontal Rolling Process in the Width Reduction of Slab [J]. J Mater Process Technol, 2000, 101(1): 146.

XIONG Shang-wu, ZHENG Gui-fang, LIU Xiang-hua, et al. Analysis of the Non-Steady State Vertical-Horizontal Rolling Process in Roughing Trains by the Three-Dimensional Finite Element Method [J]. J Mater Process Technol, 2002, 120(1-3): 53.

YU Hai-liang, LIU Xiang-hua, ZHAO Xian-ming, et al. FEM Analysis for V-H Rolling Process by Updating Geometric Method [J]. J Mater Process Technol, 2006, 180(1-3): 323.

YU Hai-liang, LIU Xiang-hua, LI Chang-sheng. Influence of Groove Fillet Radii of Edger Roll on Slab Deformation [J]. Iron Steel, 2006, 41(6): 4751.

Esa Ervasti, ULF Stahlberg. Behavior of Longitudinal Surface Cracks in the Hot Rolling of Steel Slabs [J]. J Mater Process Technol, 1999, 94(2): 141.

Esa Ervasti, ULF Stahlberg. Transversal Cracks and Their Behavior in Hot Rolling of Steel Slabs [J]. J Mater Process Technol, 2000, 101(1): 312.

Nobuki Yukawa, Takashi Ishikawa, Yoshinori Yoshida, et al. Influence of Rolling Condition on Deformation of Surface Micro-Defect in Plate Rolling [J]. Tetsu-to-Hagané, 2005, 91(12): 861 (in Japanese).

Chen J H, Wang Q, Wang G Z, et al. Fracture Behavior at Crack Tip—a New Framework for Cleavage Mechanism of Steel [J]. Acta Mater, 2003, 51(7): 1841.

LIU Xiang-hua, YU Hai-liang, LI Chang-sheng, et al. Behavior of Comer Surface Cracks in V-H Rolling Process of Steel Slabs [A]. B de Lamberterie, eds. Steel Rolling 2006 [C]. Paris: 2006. 38.

YU Hai-liang, LIU Xiang-hua, LI Chang-sheng, et al. Behavior of Transversal Crack on Slab Corner During V-H Rolling Process [J]. J Iron Steel Res Int, 2006, 13(6): 31.

WANG Yan-bo. Metal-Plastic Working, Theory and Technology of Rolling [M]. Beijing, China, Metallurgy Industry Press, 1988 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by State Basic Research Key Projects (973) of China (2006CB605208-1); National Natural Science Foundation of China (50534020)

Rights and permissions

About this article

Cite this article

Yu, Hl., Liu, Xh. & Wang, Gd. Analysis of Crack Tip Stress of Transversal Crack on Slab Corner During Vertical-Horizontal Rolling Process by FEM. J. Iron Steel Res. Int. 15, 19–26 (2008). https://doi.org/10.1016/S1006-706X(08)60119-3

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(08)60119-3