Abstract

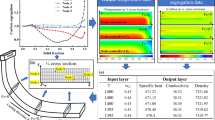

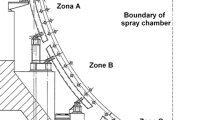

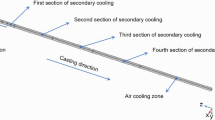

The continuous casting process is used for solidifying molten steel into semi-finished steel. The technology of secondary cooling is extremely important for output of the casting machine and billet quality. A dynamic water model was introduced, including solidification model in the secondary cooling, feedforward control strategy based on continuous temperature measurement in tundish, and feedback control strategy based on surface temperature measurement. The mathematical model of solidification process was developed according to the principle of solidification, and the solidification model was validated by measuring billet shell thickness through shooting nail and sulfur print. Primary water distribution was calculated by the solidification model according to procedure parameters, and it was adjusted by the other two control strategies online. The model was applied on some caster and billet quality was obviously improved, indicating that the dynamic water model is better than conventional ones.

Similar content being viewed by others

References

SHI Chen-xing. Practical Casting Metallurgy Technology [M]. Beijing, China: Metallurgical Industry Press, 1998 (in Chinese)

ZHANG Ke-qiang, LIN Xian, GAO Hai, et al. Application of Level 2 Distribution of Spraying Water in Continuous Casting [J]. Iron and Steel, 2006, 41(1): 39 (in Chinese).

Maehara Y. Surface Cracking Mechanism of Continuously Cast Low Alloy Steel Slabs [J]. Materials Science and Technology. 1990, 6(9): 793 (in Chinese).

Brimacombe J. K, Sorimachi K. Crack Formation in the Continuous Casting of Steel [J]. Metallurgical Transactions, 1977, 8B(3): 489.

Camisani F R, Craig I K, Pistorius P C. Speed Disturbance Compensation in the Secondary Cooling Zone in Continuous Casting [J]. ISIJ International, 2000, 40(5): 469.

Louhenkilpi Seepo. Real-Time Simulation of Heat Transfer in Continuous Casting [J]. Metallurgical Transactions, 1993, 24B(3): 685.

Euntai Kim. A New Approach to Numerical Stability Analysis of Fuzzy Control Systems [J]. IEEE Trans on Systems, 2001, 31(1): 107.

Camisani F R, Craig I K, Pistorius P C. Specification Framework for Control of the Secondary Cooling Zone in Continuous Casting [J]. ISIJ International, 1998, 38(5): 447.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Hi-Tech Research and Development Program of China (2006AA040307)

Rights and permissions

About this article

Cite this article

Liu, Wh., Xie, Z., Ji, Zp. et al. Dynamic Water Modeling and Application of Billet Continuous Casting. J. Iron Steel Res. Int. 15, 14–17 (2008). https://doi.org/10.1016/S1006-706X(08)60023-0

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(08)60023-0