Abstract

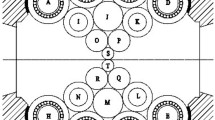

The acting force on the roll system of Sendzimir mill was analyzed using 3D FEM. The roll gap pressure distribution and the acting force between rolls S andO, rollsO and I, rollsO and J, rolls I and A, rolls I and B, as well as rolls J and B were analyzed. The results showed that the roll gap pressure mainly affected the roll surface layer, 50 mm for backup roll; the roll gap pressure distribution is of double peaks among the work roll, the 1st inteimediate roll (IMR), and the 2nd IMR; the maximum value of the roll gap pressure between the backup roll and the second IMR appears on the edge of the barrel of rolls; the component force presents the in-para-curve distribution. These are important for reducing the wear of rolls and the break of the backup roll and guiding for production.

Similar content being viewed by others

References

Hara Kenji, Yaraada Toshiro, Takagi Kazuhiro. Shape Controllability for Quarter Buckles of Strip in 20-High Sendzimir Mills [J]. ISIJ International, 1991, 31(6): 607.

Bercy M. Strip Profile Control on 20-Roll Sendzimir Mills [J]. Metallurgical Plant and Technology International, 1999, 22(6): 66.

Bates D G, Ringwood J V, Holohan A M. Robust Shape Control in a Sendzimir Cold-Rolling Steel Mill [J]. Control Eng Practice, 1997, 5(12): 1647.

Gunawardene G W D M, Grimble M J, Thomson A. Static Model for Sendzimir Cold-Rolling Mill [J]. Met Technol, 1981, 8(7): 274.

YU Hai-liang, LIU Xiang-hua, LEE Gyoo-Taek. Contact Element Method With Two Relative Coordinates and Its Application of Prediction of Strip Profile for a Sendzimir Mill [J]. ISIJ International, 2007, 47(7): 996.

YU Hai-liang, LIU Xiang-hua, LEE Gyoo Taek. Analysis to Rolls Deflection of Sendzimir Mill by 3D FEM [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(3): 600.

LIU Xiang, LIU Mei-long. Research on the Rolling Force of ZR-22BS-42 Type Sendzimir Mill [J]. Heavy Machinery, 1999, (6): 34 (in Chinese).

PAN Chun-jiu. 20-High Sendzimir Mill and High Precise Cold Rolling Production [M]. Beijing, China: Metallurgical Industry Press, 2003 (in Chinese).

YU Hai-liang, LIU Xiang-hua, ZHAO Xian-ming. Numerical Analysis to Rolling Pressure Distribution of Plane View Pattern Controlling Pass of Plate Rolling [J]. Journal of Plasticity Engineering, 2005, 12(4): 51 (in Chinese).

LIU Li-zhong, LIU Xiang-hua, WANG Guo-dong. Simulation Analysis of Double Normal Pressure Peaks [J]. Chinese Journal of Mechanical Engineering, 2001, 37(7): 30 (in Chinese).

XIE Hong-biao, XIAO hong, ZHANG Guo-min, et al. Analysis on Rolling Pressure Distribution of Strip With Different Reductions by Explicit Dynamic FEM [J]. Journal of Iron and Steel, 2002, 14(6): 33 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (50534020)

Rights and permissions

About this article

Cite this article

Yu, Hl., Liu, Xh., Wang, C. et al. Analysis of Roll Gap Pressure in Sendzimir Mill by FEM. J. Iron Steel Res. Int. 15, 30–33 (2008). https://doi.org/10.1016/S1006-706X(08)60007-2

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(08)60007-2