Abstract

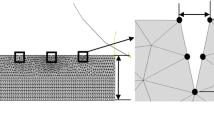

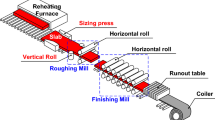

The behavior of transversal cracks on the surface of the slab corner during vertical and horizontal (V-H) rolling process with flat vertical roll and groove vertical roll was simulated by explicit dynamic finite element method. The closure and growth of crack and the contact pressure on surfaces of the crack in contacting zone between slab and roll during rolling process were analyzed. The results showed that during vertical rolling process, when the groove vertical roll is used, the maximum contact pressure on surfaces of the crack is 115 MPa, and the closure of crack is stable; when the flat vertical roll is used, the maximum contact pressure on surfaces of the crack is 70 MPa, and it fluctuates greatly. During horizontal rolling process, when groove vertical roll is used, the contact pressure becomes zero which may accelerate the growth of crack; when flat vertical roll is used, there is still contact pressure. The calculated results are in good agreement with the results of test.

Similar content being viewed by others

References

David C, Bertrand C, Chenot J L, et al. A Transient 3D FEM Analysis of Hot Rolling of Thick Slabs [A]. Pittman J F T, Wood R D, Alexander J M, ed. Proceedings of Numiform ’86 [C]. Balkema, Gothenburg, United Kingdom: Pineridge Press, 1986. 219–224.

LIU H, GAO C R, WANG G D, et al. Effection of Edger Share on the Slab Profile [J]. Journal of Plasticity Engineering, 2003, 10(5): 86–88.

XIONG Shang-wu, LIU Xiang-hua, WANG Guo-dong, et al. A Three-Dimensional Finite Element Simulation of the Vertical-Horizontal Rolling Process in the Width Reduction of Slab [J]. Journal of Materials Processing Technology, 2000, 101(1): 146–151.

XIONG Shang-wu, ZHENG Gui-fang, LIU Xiang-hua, et al. Analysis of the Non-Steady State Vertical-Horizontal Rolling Process in Roughing Trains by the Three-Dimensional Finite Element Method [J]. Journal of Materials Processing Technology, 2002, 120(1-3): 53–61.

Chung W K, Choi S K, Thomson P F. Three-Dimensional Simulation of the Edge Rolling Process by the Explicit Finite-Element Method [J]. Journal of Materials Processing Technology, 1993, 38(1-2): 85–101.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by State Ministry of Science and Technology of China (G2000067208-4)

Rights and permissions

About this article

Cite this article

Yu, Hl., Liu, Xh., Li, Cs. et al. Behavior of Transversal Crack on Slab Corner During V-H Rolling Process. J. Iron Steel Res. Int. 13, 31–37 (2006). https://doi.org/10.1016/S1006-706X(06)60106-4

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(06)60106-4