Abstract

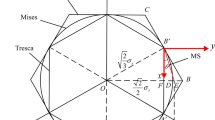

Using the twin shear stress yield criterion, the surface integral of the co-line vectors, and the integration depending on upper limit, Kobayashi’s three-dimensional velocity field of rolling was analyzed and an analytical expression of rolling torque and single force was obtained. Through redoing the same experiment of rolling pure lead as Sims, the calculated results by the above expression were compared with those of Kobayashi and Sims formulae. The results show that the twin shear stress yield criterion is available for rolling analysis and the calculated results by the new formula are a little higher than those by Kobayashi and Sims ones if the reduction ratio is less than 30%.

Similar content being viewed by others

References

OH S I, Kobayashi S. An Approximate Method for a Three-Dimensional Analysis of Rolling [J]. Int J Mech Sci, 1975, 17(4): 295–305.

Kobayashi S. Metal Forming and the Finite Element Method [M]. New York: Oxford University Press, 1989.

Kazunori KATO, Tadao MUROTA, Toshihiko KUMAGAI. Flat-Rolling of Rigid-Perfectly Plastic Solid Bar by the Energy Method [J]. J Jap Soc Tech Plasticity, 1980, 21(231): 359–369 (in Japanese).

LI G-J, Kobayashi S. Numerical Analysis of Forming Processes [M], New York: John Wiley and Sons Ltd, 1984.

YU Mao-hong. Twin Shear Stress Yield Criterion [J]. Int J Mech Sci, 1983, 25(1): 71–74.

ZHAO De-wen, WANG Guo-dong, BAI Guang-run. Theoretical Analysis of the Wire Drawing Through Two Roller Dies in Tandem [J]. Science in China (Series A), 1993, 36(5): 632–640.

WANG Guo-dong, ZHAO De-wen. Modern Materiel Forming Mechanics [M]. Shenyang: Northeastern University Press, 2004 (in Chinese).

ZHAO De-wen, GUO Chang-wu, LIU Xiang-hua. Surface Integral of Three-Dimensional Velocity Field for Square Bar Drawing Through Conical Die [J]. Trans Nonferrous Met Soc China, 1996, 6(3): 131–139.

ZHAO De-wen. Mathematical Solution of Continuum Forming Force [M]. Shenyang: Northeastern University Press, 2003 (in Chinese).

Sims R B. The Calculation of Roll Force and Torque in Hot Rolling Mills [J]. Proc Inst Mech Engrs, 1954, 168(6): 191–200.

Richardson G J. Worked Examples in Metalworking [M]. London: The Chameleon Press Limited, 1985.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (50474015)

Rights and permissions

About this article

Cite this article

Zhao, Dw., Xie, Yj., Liu, Xh. et al. Three-Dimensional Analysis of Rolling by Twin Shear Stress Yield Criterion. J. Iron Steel Res. Int. 13, 21–26 (2006). https://doi.org/10.1016/S1006-706X(06)60104-0

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(06)60104-0