Abstract

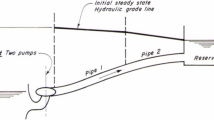

Water hammer following the tripping of pumps can lead to overpressure and negative pressure. Reduction in overpressure and negative pressure may be necessary to avoid failure, to improve the efficiency of operation and to avoid fatigue of system components. The field tests on the water hammer have been conducted on the pump rising pipeline system with an air chamber. The hydraulic transient was simulated using the method of characteristics. Minimizing the least squares problem representing the difference between the measured and predicted transient response in the system performs the calibration of the simulation program. Among the input variables used in the water hammer analysis, the polytropic exponent, the discharge coefficient and the wave speed were calibrated. The computer program developed in this study will be useful in designing the optimum parameters of an air chamber for the real pump pipeline system. The correct selection of air chamber size and the effect of the inner diameter of the orifice to minimize water hammer have been investigated by both field measurements and numerical modeling.

Similar content being viewed by others

References

MITOSEK M. Study of transient vapor cavitation on series pipe systems[J]. Journal of Hydraulic Engineering, ASCE, 2000, 126(12): 904–911

ISMAIER A., SCHLUCKER E. Fluid dynamic interaction between water hammer and centrifugal pumps[J]. Nuclear Engineering and Design, 2009, 239: 3151–3154.

KIM S. Impulse response method for pipeline systems equipped with water hammer protection devices[J]. Journal of Hydraulic Engineering, ASCE, 2008, 134(7): 961–969

NIKPOUR M. R., NAZEMI A. H. and HOSSEINZADEHDALIR A. et al. Experimental and numerical simulation of water hammer[J]. Arabian Journal for Science and Engineering, 2014, 39(4): 2669–2675

STEPHENSON D. Simple guide for design of air vessels for water hammer protection of pumping lines[J]. Journal of Hydraulic Engineering, ASCE, 2002, 128(8): 792–797

GIUSEPPE D. M., NICOLA F. Simplified approach for the optimal sizing of throttled air chambers[J]. Journal of Hydraulic Engineering, ASCE, 2012, 138(12): 1101–1109.

WYLIE E. B., STREETER V. L. Fluid transients in systems [M]. London, UK: Prentice Hall, 1993.

MOODY F. J. Introduction to unsteady thermofluid mechanics [M]. Hoboken, New Jersey, USA: John Wiley and Sons, 1990.

RADOSLAV K., ZDRAVKO V. and MARIO S. Truncated method of characteristics for quasi-two dimensional water hammer model[J]. Journal of Hydraulic Engineering, ASCE, 2014, 140(6): 040014013.

ZHAO M., GHIDAOUI M. S. Efficient ruasi-two-dimensional model for water hammer problems[J]. Journal of Hydraulic Engineering, ASCE, 2003, 129(12): 1007–1013.

GRAZE H. R. Disussion of pressure surge attenuation utilizing an air chamber by Wood D. J.[J]. Journal of the Hydraulics Division, ASCE, 1971, 97(3): 455–459

Author information

Authors and Affiliations

Corresponding author

Additional information

Biography: KIM Sang-Gyun (1959-), Male, Ph. D.

Rights and permissions

About this article

Cite this article

Kim, SG., Lee, KB. & Kim, KY. Water hammer in the pump-rising pipeline system with an air chamber. J Hydrodyn 26, 960–964 (2014). https://doi.org/10.1016/S1001-6058(14)60105-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1001-6058(14)60105-0