Abstract

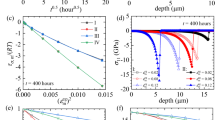

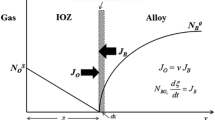

In high temperature oxidation environment, the oxidation reaction will induce variations in material parameters, such as Young’s modulus, thermal expansion coefficient (CTE), coefficient of oxygen diffusion (COD), etc. The oxidation-induced material parameter variations should be considered in high temperature mechanical analysis. In this paper, high temperature oxidation behavior of an oxide film/metal substrate system was investigated through a modified phase field approach. The oxidative stress and oxidation weight gain induced by high temperature oxidation were studied. Effects of Young’s modulus, COD and CTE on oxidative stress in the oxide film were studied particularly. The simulation results showed that a better agreement with the experimental results could be obtained when considering the oxidation-induced material parameter variations in the high temperature mechanical analysis of oxide film/metal substrate system. The simulation results demonstrated that oxidative stress and oxidation weight gain were more sensitive to the variation of Young’s modulus than to the variations of COD and CTE.

Similar content being viewed by others

References

Evans, A.G., Mumm, D.R., Hutchinson, J.W., Meier, G.H. and Pettit, F.S., Mechanisms controlling the durability of thermal barrier coatings. Progress in Materials Science, 2001, 46: 505.

Padture, N.P., Gell, M.E. and Jordan, H., Thermal barrier coatings for gas-turbine engine applications. Science, 2002, 296: 280.

Panicaud, B., Grosseau-Poussard, J.L., Girault, P., Dinhut, J.F. and Thiaudiere, D., Comparison of growth stress measurements with modelling in thin iron oxide films. Applied Surface Science, 2006, 252: 8414.

Drexler, J.M., Gledhill, A.D., Shinoda, K., Vasiliev, A.L., Reddy, K.M., Sampath, S. and Padture, N.P., Jet engine coatings for resisting volcanic ash damage. Advanced Materials, 2011, 23: 2419.

Chou, K.C., A kinetic model for oxidation of Si-Al-O-N materials. Journal of the American Ceramic Society, 2006, 89(5): 1568–1576.

Dong, X.L., Feng, X. and Hwang, K.C., Stress-diffusion interaction during oxidation at high temperature. Chemical Physics Letters, 2014, 614: 95–98.

Dong, X.L., Feng, X. and Hwang, K.C., Diffusion and stress coupling effect during oxidation at high temperature. Journal of the American Ceramic Society, 2013, 96(1): 44–46.

Ma, Y.J., Yao, X.F., Hao, W.F., Chen, L.J. and Fang, D.N., Oxidation mechanism of ZrB2/SiC ceramics based on phase-field model. Composites Science and Technology, 2012, 72: 1196–1202.

Yang, F, Fang, D.N. and Liu, B., A theoretical model and phase field simulation on the evolution of interface roughness in the oxidation process. Modeling and Simulation in Materials Science and Engineering, 2012, 20: 015001.

Yang, F., Fang, D.N. and Liu, B., Analysis on high-temperature oxidation and growth stress of iron-based alloy using phase field method. Applied Mathematics and Mechanics (English Edition), 2011, 32(6): 757–764.

Yang, F., Fang, D.N. and Liu, B., Interplay between fracture and diffusion behaviors: Modeling and phase field computation. Computational Materials Science, 2011, 50: 2554–2560.

Ruan, J.L., Pei, Y.M. and Fang, D.N., On the elastic and creep stress analysis modeling in the oxide scale/metal substrate system due to oxidation growth strain. Corrosion Science, 2013, 66: 315–323.

Haugsrud, R., On the high-temperature oxidation of nickel. Corrosion Science, 2003, 45(1): 211–235.

Tolpygo, V.K., Clarke, D.R., The lateral growth strain accompanying the formation of a thermally grown oxide. Acta Materialia, 2000, 48(13): 3283–3293.

He, R.J., Zhang, R.B., Zhu, X.L., Wei, K., Qu, Z.L., Pei, Y.M. and Fang, D.N., Improved Green strength and Green machinability of ZrB2-SiC through gelcasting based on a double gel network. Journal of the American Ceramic Society, 2014, 97(8): 2401–2404.

Jin, X.X., He, R.J., Zhang, X.H. and Hu, P., Ablation behavior of ZrB2-SiC sharp leading edges. Journal of Alloys and Compounds, 2013, 566: 125–130.

He, R.J., Hu, P., Zhang, X.H. and Liu, C., Gelcasting of complex-shaped ZrB2-SiC ultra-high temperature ceramic components. Materials Science and Engineering: A, 2012, 556(30): 494–499.

He, R.J., Zhang, X.H., Hu, P., Liu, C. and Han, W.B., Aqueous gelcasting of ZrB2-SiC ultra-high temperature ceramics. Ceramics International, 2012, 38(7): 5411–5418.

Reddy, K.P.R., Smialek, J.L. and Cooper, A.R., O-18 tracer studies of AL2O3 scale formation on nicral alloys. Oxidation of Metals, 1982, 17(5–6): 429–449.

Monteverde, F., The thermal stability in air of hot-pressed diboride matrix composites for uses at ultra-high temperatures. Corrosion Science, 2005, 47(8): 2020–2033.

Opila, E., Levine, S. and Lorincz, J., Oxidation of ZrB2- and HfB2-based ultra-high temperature ceramics: Effect of Ta additions. Journal of Materials Science, 2004, 39(19): 5969–5977.

Chen, L.Q., Phase-field method for microstructure evolution. Annual Review of Materials Research, 2002, 32: 113–140.

Boettinger, W.J., Warren, J.A., Beckermann, C. and A.Karma3, Phase-field simulation for solidification. Annual Review of Materials Research, 2002, 32: 163–194.

H.Jia-Mian, Sheng, H.G., Zhang, J.X., Nan, C.W. and Chen, L.Q., Phase-field simulation of strain-induced domain switching in magnetic thin films. Applied Physics Letters, 2011, 98(11): 112505.

Wang, C., Zhang, R.B., Pei, Y.M. and Fang, D.N., Phase field simulation for high-temperature oxidation behavior of thermal barrier coatings under shot peening. International Journal of Applied Mechanics, 2012, 4(4): 1250038.

Huntz, A.M., Calvarin, A.G. and Evans, H.E., Comparison of oxidation-growth stresses in NiO film measured by deflection and calculated using creep analysis or finite-element modeling. Oxidation of Metals, 2002, 57(5–6): 499–521.

Obata, Y. and Noda, N., Optimum material design for functionally gradient material plate. Archive of Applied Mechanics, 1996, 66: 581–589.

Yang, F., Liu, B. and Fang, D.N., Interplay between fracture and diffusion behaviors Modeling and phase field computation. Journal of Zhejiang University-Science A (Applied Physics & Engineering), 2010, 11(10): 789–793.

Author information

Authors and Affiliations

Corresponding author

Additional information

Project supported by the the Foundation of Beijing Jiaotong University (KCRC14002536).

Rights and permissions

About this article

Cite this article

Wang, C., Ai, S. & Fang, D. Effect of oxidation-induced material parameter variation on the high temperature oxidation behavior of nickel. Acta Mech. Solida Sin. 29, 337–344 (2016). https://doi.org/10.1016/S0894-9166(16)30237-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S0894-9166(16)30237-3