Abstract

This review aims to provide a comprehensive overview of the development and current understanding of GaAs and InAs heterostructures, with a special emphasis on achieving high material quality and high-mobility two-dimensional electron gases (2DEGs). The review discusses the evolution of structural designs that have significantly contributed to the enhancement of electron mobility, highlighting the critical considerations of scattering mechanisms of the 2DEGs. In addition, this review examines the substantial contributions of Molecular Beam Epitaxy (MBE) to these developments, particularly through advancements in vacuum technology, source material purification, and precision control of growth conditions. The intent of this review is to serve as a useful reference for researchers and practitioners in the field, offering insights into the historical progression and technical details of these semiconductor systems.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Over the past several decades, the development of semiconductor heterostructures has been transformative for both the field of fundamental physics and the advancement of modern electronic and quantum device technologies. By integrating multiple semiconductor materials with distinct electronic properties, these heterostructures allow for unparalleled control over electronic behavior, which is crucial for the functionality of a wide array of high-tech applications.

Semiconductor heterostructures are particularly pivotal in the creation of high-electron-mobility transistors (HEMTs), which are essential for applications requiring high-frequency and high-speed operation [1–5]. These devices are fundamental components in systems ranging from satellite communications to advanced radar systems, underpinning much of our modern telecommunications infrastructure. The enhanced performance and efficiency of HEMTs are directly attributable to the unique electronic properties facilitated by the heterostructure design, which optimizes electron flow and minimizes scattering.

The utility of semiconductor heterostructures extends beyond practical electronic applications; they are also crucial in fundamental research [6–12]. These materials have enabled scientists to observe and study quantum phenomena with unprecedented precision. One of the most notable discoveries made by these heterostructures is the fractional quantum Hall effect, observed in high-mobility two-dimensional electron gases (2DEGs) within GaAs/AlGaAs heterostructure systems [13]. This phenomenon, which involves the formation of exotic quantum states under high magnetic fields, has provided deep insights into electron-electron interactions and has significant implications for the theoretical models in condense matter physics and materials science.

Moreover, the role of semiconductor heterostructures in quantum computing has increasingly captured the interest of researchers. This interest is particularly focused on topological quantum computing, which utilizes the properties of quasi-particles that obey non-Abelian statistics [12, 14–17]. These quasi-particles promise an inherently fault-tolerant approach to information processing due to the topological nature of their quantum states, which are robust against local disturbances. This robustness is crucial for overcoming one of the primary challenges in conventional quantum computing—decoherence, where quantum information is lost due to interactions with the environment [18].

In pursuit of these capabilities, researchers have been focusing on several approaches over the past two decades. Notably, the manipulation of \(\nu =5/2\) fractional quantum Hall state, platformed by GaAs-based heterostructures [17], and the engineering of Majorana zero-modes (MZMs), majorly platformed by InAs-based superconductor-semiconductor hybrid structures [12, 15, 16, 19], are suitable choices that attracted significant research interest. While the theoretical framework supporting these approaches is well established [14, 20, 21], the realization in practical devices continues to face significant challenges. One of the most critical hurdles is the material quality, namely, material purity, crystal defect density, interface roughness, and other properties that affect the performance of the 2DEG. Similar to the discovery of the fractional quantum Hall effect, this was not the first instance where a gap between theoretical predictions and experimental realizations was caused by insufficient material quality. For instance, the FQHE was not observed until the 2DEG mobility in the GaAs/AlGaAs system reached 9 × 104 cm2/Vs [8]. Enhancing material quality continues to be one of the most critical research priorities within these material systems.

1.1 Material quality and electron mobility

The electron mobility is expressed mathematically as

where \(v_{d}\) is the drift velocity of electrons and E is the electric field applied to the material. The mobility quantifies the ease with which electrons can move through a semiconductor or conductor when subjected to an electric field. Especially, in the transport measurement of a 2DEG system, the mobility can also be expressed as

where σ is the zero-field conductivity, e is the charge of electrons, and n is the areal carrier density of the 2DEG. This relationship implies that high mobility often reflects the measurement of high conductivity under conditions of relatively low carrier density.

The relationship between the electron mobility and material quality is an involved topic and some discussions will be made in the following sections of this review. It is well-established that at low temperatures (below 1K) where scattering events caused by thermal vibration of semiconductor atoms are sufficiently weak [22], high electron mobility indicates that the material system that contains the 2DEG has fewer scattering centers such as impurities and crystal defects, allowing electrons to travel longer distances without significant scattering.

For instance, in a 2DEG system where the mobility reaches as high as 107 cm2/Vs, the mean-free path of electrons can extend to the micrometer scale [23]. Under such conditions, the 2DEG system becomes an ideal platform for observing and studying many-body quantum phases due to the dominance of electron-electron interactions. Moreover, in the studies of topological quantum computing with the detection of Majorana zero-modes, those 2DEGs, normally located only 5-10 nm beneath the heterostructure surface, are required to maintain a high mobility of 106 cm2/Vs to 107 cm2/Vs [11]. Achieving such high mobility levels necessitates significant advancements in both the structural design and growth techniques of the heterostructures [11, 12, 24].

1.2 Molecular Beam Epitaxy (MBE) for crystal growth

Molecular Beam Epitaxy (MBE) is a highly sophisticated vacuum deposition technique used primarily for producing single crystals of semiconductors and other complex materials. Since the first publications on the use of MBE for the fabrication of semiconductor devices in the 1970s by Cho and Arthur et al. (see for example, [25–30]), the technique has increasingly become central to semiconductor technology as well as a formidable tool in the fields of condensed matter physics and materials science [31].

The primary advantage of MBE lies in its ability to exert precise control over the growth and structure of the materials it produces, for example, the control of layer thickness in an atomic-layer level and sharp interface between layers. This precise control, especially the ability to create abrupt transitions between layers, has opened up vast possibilities for research on low-dimensional systems, such as 2DEGs.

To provide a concise overview of the MBE technique, it involves directing beams of elemental or compound molecules onto a heated substrate where they condense and form a crystalline layer. This process takes place in an ultra-high vacuum (UHV) environment to prevent contamination and ensure the purity of the growing crystal. The source materials, often loaded in effusion cells, are heated until they sublimate and release a directed beam of molecules or atoms towards the substrate. The control of growth conditions, such as substrate temperatures, allows precise registry of the atoms of the grown film thus enables the production a large-area, single-crystal film.

Over the years, advancements in MBE technology have significantly improved its capability and applicability. Innovations such as the refined effusion cell design and enhanced real-time monitoring techniques like Reflection High-Energy Electron Diffraction (RHEED) have further elevated the quality of the growth and enabled the real-time diagnostics of the growth process.

This review aims to provide a comprehensive overview of the development and current understanding of GaAs and InAs heterostructures, with a special emphasis on achieving high-mobility 2DEGs. We have discussed the evolution of structural designs that have significantly contributed to the enhancement of electron mobility, highlighting the critical considerations of scattering mechanisms of the 2DEG system. In addition, this review examines the substantial contributions of MBE to these developments, particularly through advancements in vacuum technology, source material purification, and precision control of growth conditions.

The intent of this review is to serve as a useful reference for researchers and practitioners in the field, offering insights into the historical progression and technical nuances of these semiconductor heterostructures. As the research needs of condensed matter physics, material science, and quantum computing technologies continues to evolve, the information provided here aims to support ongoing research and future advancements by detailing the foundational technologies and methodologies that underpin current practices.

2 GaAs structural design

Although the development of growth technique is not the major point of this section, it is reasonable to mention since it is where the journey of GaAs-based heterostructures began. After the development of liquid phase epitaxy (LPE), which initially allowed for the creation of muti-layer structures with varying bandgaps (for a review, see [32]), the introduction of molecular beam epitaxy (MBE) in the 1970s was a significant breakthrough given it enable the ultra-precise control of deposition of atomic layers.

In the early stage of MBE development, GaAs was one of the most essential and pioneering materials that researchers used to test and refine the technology (see for example, [25–28, 33–35]). This choice was driven by several factors, such as its semiconductor properties, good thermal stability and easy handling procedures in the vacuum environment. Early experiments with GaAs in MBE setups helped in understanding the kinetics and thermodynamics of layer growth, and these developments on the opposite side made GaAs-based heterostructure one of the most established material systems among semiconductor systems in both theoretical and experimental aspects.

For the GaAs-based heterostructures, the first milestone in the development of structural design came from the introduction of modulation doping, reported by Dingle et al. in late 1970s [36]. The structure was based on a single heterojunction (SHJ) design shown in Fig. 1. The structure was grown on a GaAs substrate. After growing a thick smoothing layer of undoped GaAs to reduce the influence of surface defects of the substrate, an n-doped AlGaAs layer was grown on top of it. The key of this design was that the dopant atoms were spatially separated from the mobile electron channel formed at the GaAs/AlGaAs interface so that the scattering from ionized impurities (the Si atoms) was minimized. The concept of modulation doping set the foundation of the structural design of the GaAs heterostructures. Since the inception of this concept, the 2DEG mobility of GaAs/AlGaAs has been increased by a factor of over several thousands. From the following development of high-electron-mobility transistors (HEMTs) to the samples that produced the highest 2DEG mobility recorded, the structural design was more or less the refinement and modification of the SHJ.

In the following decade, the material quality was considerably pushed forward, indicated by the improvement of electron mobility of the 2DEG from 5000 cm2/Vs to 1.2 × 106 cm2/Vs [37–42]. Although the continuous development of MBE technique played an important role, the evolution of the structural design of this type of material is also crucial. In this stage, the modification focused on improving the “efficiency” of the modulation doping. Instead of the conventional bulk doping of the AlGaAs layer, the planar doping, or so-called delta-doping was invented (for a review, see [43]). After the growth of a AlGaAs spacer layer, the growth is interrupted and a very thin layer of Si is completely deposited before the growth of AlGaAs starts again. Comparing with bulk doped AlGaAs layer, the ionized impurity area is confined in a very thin region so that the remote ionized impurity scattering is reduced. At the same time, the Si atoms are overall closer to the heterojunction. Naively speaking, given the same dopant density, the transferred charge density to the 2DEG is higher. Other modifications based on the planar doping technique also took place, including varying the thickness of AlGaAs barrier [40], preforming multiple layers of planar doping and setting large spacers between them [39].

In this stage, one of the most promising results was reported by Pfeiffer et al. at Princeton/Bell Lab. In their work, GaAs/Al0.35Ga0.65As structure was grown and the planar doping was performed with a 70 nm setback. The sample was put into van der Pauw geometry for transport characterization at 350 mK and a 2DEG mobility of 11.7 × 106 cm2/Vs was obtained [42]. Notably, the work also discussed the importance of illumination during transport measurement. In AlxGa1-xAs where x > 20%, a deeper donor state of Si atoms (∼135 meV compared to ∼10 meV) and illumination is needed for charge transferring. This is the so-called “D-X centers” (for detailed information of D-X centers, see [44, 45]). It is also worth mentioning that Pfeiffer et al. later explored an inverse-heterojunction design, in which GaAs layer was grown after the planar doped AlGaAs layer and discussed the asymmetry compared with the normal design [46]. The analysis and discussion showed that the Si dopant atoms thermally migrated towards the direction of growth and this migration enlarged the ionized impurity scattering of the 2DEG. The growth technique nowadays normally contains a cooling procedure after the semiconductor growth is interrupted for doping to minimize this type of migration.

The planar doping technique based on a single-heterojunction design also has its limitations in pushing the 2DEG mobility higher. Although decreasing the thickness of setback between the Si dopants and the heterointerface can raise the 2DEG density, the scattering from the ionized impurities is raised simultaneously. Moreover, at higher density, the wavefunction of the electrons gets more overlapped with the heterojunction interface, thus gets more influence by the interface scattering [47, 48]. Compared to the SHJ design, the quantum well design attracted more research interest in the next stage of the material design evolution given its superior property of carrier confinement [49–51]. In an AlGaAs/GaAs/AlGaAs quantum well design, it is possible to have one planar-doping Si area on each side of the barrier such that the Si atoms contribute to the 2DEG density on both sides without shortening the distance from the 2DEG to the ionized Si.

To put the concept of modulation-doped quantum well into real structural design, and further reduce impurity scattering, several approaches focused on improving the confinement of quantum well were reported, such as multiple quantum well design [51]. Friedland et al. presented the idea of using short-period AlAs/GaAs superlattice to smooth the potential fluctuations of the ionized dopants [52]. The key point of this approach is to utilize the X-conduction band of AlAs layers. At high enough doping concentration, the X-conduction band states of AlAs layers are occupied [53], which form thin layers of X-electrons that effectively screen the ionized impurities without contribution to parallel conductance. This short-period superlattice doping technique was later discussed by Umansky et al. [54]. In Umansky et al.’s work, the 2DEG mobility was pushed to 35 × 106 cm2/Vs. The work also pointed out that with this type of doping procedure, a lower AlAs mole fraction of AlGaAs spacer can be used such that the background scattering can be reduced. Moreover, the planar doping was actually preformed in the GaAs layers of the superlattice to avoid the effect of D-X centers. Currently, the state-of-the-art GaAs-based structures that created 2DEGs with recorded mobility basically followed the idea of superlattice doping. Instead of growing several periods of AlAs/GaAs superlattice, the most recent design chose to build a thin AlAs/GaAs/AlAs quantum well and proceed planar doping inside the GaAs well [23, 55–58]. Therefore, this design is named as the “doping well” design. Figure 2 shows a typical layer structure of this design.

Along with the evolution of the design of these heterostructures, one basic question that always attracted researchers’ interest was the limiting factors of the 2DEG mobility. As previously discussed, mobility describes how far and fast the charge carriers can move when an electric field is applied, without being significantly scattered. Central to these concerns are the various scattering mechanisms. Since the introduction of the first GaAs-based 2DEG system, numerous studies have been conducted to understand the scattering mechanisms through both theoretical analyses and experimental investigations [22, 59–66]. To provide an overview of the key scattering mechanisms that researchers considered, several of them are listed below:

-

1.

Ionized impurity scattering. Ionized impurity scattering occurs when free charge carriers are deflected by the Coulomb fields of ionized impurity atoms within the semiconductor. In the context of 2DEG mobility, the ionized impurity scattering is mainly caused by dopant atoms after donating or accepting electrons. In most cases of the modulation doping design, the dopant atoms are spatially separated from the 2DEG region. But the Coulomb fields still remotely affect the 2DEG mobility.

-

2.

Interface roughness scattering. Interface roughness scattering is caused by microscopic variations at the interfaces between different materials in a heterostructure. These variations create potential fluctuations which scatter the charge carriers.

-

3.

Alloy disorder scattering. Alloy disorder scattering occurs in semiconductor alloys, such as AlGaAs, where the random substitutional placement of different atomic species (e.g., aluminum and gallium in AlGaAs) within the crystal lattice creates fluctuations in the band structure. These fluctuations can locally alter the electronic potential, leading to scattering of the charge carriers. Mitigating alloy disorder scattering involves optimizing the alloy composition and improving the uniformity of the atomic distribution of a semiconductor alloy, which is challenging. Placing the 2DEG within a layer of a pure material, such as GaAs, rather than within an alloy, is a sophisticated way to optimize the structural design.

-

4.

Background scattering. Background scattering refers to the scattering of charge carriers by background impurities and crystal defects, such as vacancies, dislocations, and grain boundaries, that are inherently present in the crystal lattice. They act as random scattering centers affecting the mobility of carriers. Mitigating background scattering involves structural consideration that minimizes the crystal defects, precise control of growth conditions, advanced growth techniques that provide high-purity growth environment, and purifying procedures of source material. Part of them will be discussed in the section of growth technique.

-

5.

Phonon scattering. Phonon scattering involves the interaction of charge carriers with phonons, which are quanta of lattice vibrations in the semiconductor material. The effect of phonon scattering increases with temperature, as higher thermal energy increases phonon activity, leading to more frequent carrier-phonon interactions.

Suggested by theoretical studies, the mobility vs. density relation, \(\mu \propto n^{\alpha} \), is often used to characterize the dominant scattering mechanisms [22]. In a 2DEG system, the value of α reflects the distribution of charged point impurities. \(\alpha \sim 1.5\) implies that the charged impurities are localized in a plane parallel to the 2DEG (planar doping or interface-related scattering), while \(\alpha \sim 0.5\) implies that the charged impurities are distributed uniformly in bulk of the structure (background scattering or alloy disorder) [22]. This approach has been heavily used to analyze the transport experiment data of the 2DEG structures.

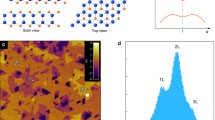

Although all the aforementioned scattering mechanisms significantly impact material quality and 2DEG mobility, research has highlighted that background scattering is increasingly becoming the dominant factor as structural designs continue to improve. Several representative studies have underscored this trend. Based on an SHJ structure, Umansky et al. experimentally measured the 2DEG mobility as a function of the spacer thickness between the doping and 2DEG regions, finding only a weak correlation once the spacer was sufficiently thick [65]. Complementarily, Hwang et al. theoretically analyzed the influence of various scattering mechanisms and determined that below 1K, the effect of phonon scattering diminishes in significance. Their work also highlighted that reducing the background impurity density to 1012 cm−3 and increasing the modulation doping separation to 100 nm or more could potentially achieve mobilities up to 100 × 106 cm2/Vs at a carrier density of 3 × 1011 cm−2 [22]. Utilizing a doping-well structure, Chung et al. achieved 2DEG mobilities reaching 44 × 106 cm2/Vs and subsequently 57 × 106 cm2/Vs—to the best of our knowledge, the highest ever reported [57, 58]. Figure 3 shows a low-temperature magnetotransport data of a representative high-quality GaAs 2DEG reported in Ref. [57]. Their analysis identified that to reach a target mobility of 100 × 106 cm2/Vs, critical improvements were necessary, specifically in reducing background impurity levels by improving vacuum environment and further purifying the source material.

A low-temperature full-field longitudinal magnetoresistance trace of a high-quality GaAs 2DEG system. (adopted from Ref. [57])

It is also important to note that while electron mobility is a critical indicator of sample quality, it may not be a universal one, especially in specialized research interest [66]. Studies focused on phenomena such as the fractional quantum Hall effect and the enigmatic 5/2 state have shown that other factors, including the uniformity of the electron gas and the exactitude of electronic states, are equally vital. For these specific research applications, deliberate considerations in structural design and meticulous growth processes have been implemented to optimize sample designs. For more detailed information on this topic, readers are encouraged to consult the review by Manfra et al. [23], which provides comprehensive insights into the subject.

3 InAs structural design

As discussed earlier, InAs possesses distinct material properties, including a low effective mass, narrow bandgap, and strong spin-orbit interaction. Despite these advantages, the exploration of InAs-based heterostructures and 2DEG systems commenced roughly a decade later than that of GaAs. The initial focus on GaAs was propelled by well-established growth techniques, its early adoption in commercial applications, and pivotal research breakthroughs, such as the discovery of the quantum Hall effect. In contrast, interest in InAs-based heterostructures began to surge only after GaAs technologies and methodologies, including the mastery of III-V semiconductor crystal growth and the development of molecular beam epitaxy (MBE), were firmly established. This later start also benefited from a growing understanding of the scattering mechanisms in 2DEGs, which provided a solid foundation for advancing InAs research.

Unlike GaAs, which initially utilized single-heterojunction design extensively before moving towards quantum well designs, InAs-based research was inclined towards quantum wells from an earlier stage. To illustrate a basic comparison, it is relatively straightforward to grow an epitaxial layer of AlGaAs on a GaAs substrate, effectively creating a SHJ structure. In contrast, the scenario is not as straightforward for InAs. This brings us to the first major challenge in the growth techniques for InAs-based materials. Manufacturing and performing growth experiments on InAs substrates is fraught with difficulties due to their thermal instability, chemical sensitivity, complex handling requirements, and high cost. Consequently, researchers often opt to use other semiconductor wafers as substrates for growing InAs-based structures, even for those initial attempts for InAs growth (see for example, [67, 68]).

In selecting different semiconductor materials for substrates, lattice mismatch is a primary consideration. Figure 4, adopted from [69], illustrates a lattice-constant versus bandgap energy diagram for various III-V semiconductors. It clearly highlights that GaAs and AlAs form an ideal combination due to their minimal lattice mismatch, quantified simply as ε= |aAlAs-aGaAs|/aGaAs, which results in a value of only 0.2%. This small mismatch, coupled with their significant difference in bandgap energies, ensures effective quantum confinement for constructing heterojunctions or quantum wells. In contrast, for InAs-based structures, materials like GaSb (\(\varepsilon =0.7\)%) and AlSb (\(\varepsilon =1.3\)%) exhibit the closest lattice constants. However, growing on these Sb-based substrates requires sophisticated growth techniques, including precise control of growth conditions and complex pre-growth surface treatments [70]. Initially, studies focusing on growth on Sb-based substrates were few, but they have increased significantly in recent years [71–78]. Due to its small bandgap, GaSb is not inherently semi-insulating, posing challenges but also offering advantages for certain applications like back-gated devices. To mitigate conductivity issues and enhance device functionality, researchers have employed high bandgap buffer layers. A notable example is the quaternary buffer Al0.8Ga0.2As0.07Sb0.93, which combines a high Al/Ga mole fraction for effective electron confinement with adjusted As content to ensure a lattice-matched condition. This innovative approach has sparked significant interest in recent studies, illustrating the potential for tailored material properties to meet specific research needs [77, 78]

A lattice-constant vs. bandgap energy diagram of typical III-V semiconductor compounds. (adopted from Ref. [69])

More conventionally used substrates such as GaAs (\(\varepsilon =6.7\)%) and InP (\(\varepsilon =3.1\)%) present much larger lattice mismatches, which commonly result in a large number of dislocations that enhance the background impurity scattering of the 2DEG [79]. Indeed, direct growth of InAs layer in large lattice-mismatched systems has been reported [80, 81]. In these structures, modulation-doped In0.52Al0.48As/In0.53Ga0.47As layers that are perfectly lattice matched to InP substrates acted as quantum well barriers. The thickness of InAs quantum well must be kept within an ultra-thin level (critical thickness < 4 nm) to prevent strain relaxation (for detailed information of critical thickness, see Ref. [82]). Interface roughness scattering plays an important role in these ultra-thin quantum well systems.

In most studies, intentionally designed buffer layers are employed between the substrate and the active region of the 2DEG. Uniform buffer layers consist of materials whose lattice constants are either close to that of the active region (e.g. AlSb) or strategically chosen to be at a midpoint between the substrate and the active region (e.g. In0.4Al0.6As) [83–86]. These layers typically need to be grown with sufficient thickness—sometimes several microns—to effectively mitigate the effects of lattice relaxation. Alternatively, graded buffer layers incorporate a series of semiconductor alloys, such as InxAl1-xAs, InxGa1-xAs, and AlAsySb1-y. The composition of these alloys is gradually varied so that the lattice constant transitions from matching the substrate at the bottom to aligning with the active region at the top [87–93]. Studies have directly observed through Transmission Electron Microscopy (TEM) that within the graded buffer region, most dislocations tend to bend and annihilate. As a result, these dislocations are confined to the lower layers of the structure, thereby minimizing their impact on the active region [94]. Fig. 5 depicts a cross-sectional TEM image of the graded buffer layers of an InAs/In0.53Ga0.47As quantum well structure (adopted from Ref. [95]). It was demonstrated that the defect density of the graded buffer region decreased as the layers grew, and the “pseudo-substrate” In0.8Ga0.2As region was free of dislocations. This structural design is now extensively employed in InAs-based 2DEG structures, including those targeting research areas such as topological superconductivity and Majorana zero modes [96–99].

A cross-sectional TEM image of an InAs/In0.53Ga0.47As quantum well grown on an InP substrate with graded buffer layers (adopted from Ref. [95])

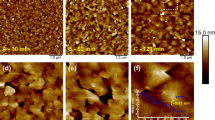

It is also worth mentioning that some studies have highlighted that, although the 2DEG active region may be dislocation-free, the surface morphology of the structure can still be affected by dislocations originating from deeper within the graded buffer layers, resulting in a cross-hatch pattern [78]. adopted from [78], Fig. 6 offers a clear comparison of atomic force microscopy (AFM) images of two InAs quantum well samples: one grown on a GaSb substrate and the other on an InP substrate with a graded buffer layer. The latter sample exhibits a distinct cross-hatch pattern, which could potentially impact the quality of the 2DEG and overall device performance. To put this into context, in research focused on Majorana zero modes, the 2DEGs are typically confined within a 10 to 20 nm thick region close to the surface and are engineered into nanowire channels. These channels usually have lengths of about 1 to 2 microns and widths ranging from 50 to 100 nm [96, 97]. Given these dimensions, the scale of fluctuation observed in the cross-hatch patterns, as shown in Fig. 6, is significant relative to the size of these devices. The potential impact of such cross-hatch patterns on device performance warrants further investigation.

(a) \(5 \mu \mathrm{m}\times 5\mu \mathrm{m}\) AFM image of an InAs quantum well sample grown on a lattice-matched GaSb substrate. (b) \(20 \mu \mathrm{m}\times 20\mu \mathrm{m}\) AFM image of an InAs quantum well sample grown on InP with an InxAl1-xAs graded buffer. (adopted from Ref. [78])

Different barrier materials have been extensively studied for InAs quantum wells, with the choice of barrier significantly impacting the well’s properties. Broadly, these barrier materials can be categorized into two groups based on their anionic composition: those containing antimony (Sb) as the anion, and those containing only arsenic (As) as the anion. Each type offers distinct electronic and structural characteristics that influence the confinement and mobility of charge carriers within the quantum wells. For quantum well barriers incorporating Sb, materials such as GaSb [100], AlSb [72, 75, 76, 100, 101], and semiconductor alloys like AlxGa1-xSb [74, 77, 78, 102] and AlAsySb1-y [84] have been extensively investigated for various scientific and technological objectives. Conversely, for barriers that contain only As, semiconductor alloys such as InxAl1-xAs and InxGa1-xAs are considered optimal choices.

From a material quality perspective, quantum well barriers that include Sb typically provide superior confinement for 2DEGs compared to those without Sb. This advantage is evident in Fig. 4, which illustrates that AlxGa1-xSb barrier can achieve a similar bandgap energy difference for quantum well confinement while introducing a significantly smaller lattice mismatch than As-based barriers, InxAl1-xAs and InxGa1-xAs. However, the growth techniques of Sb-based materials are more involved than that of As-only materials. Particularly noteworthy are the “interface type problems” observed at InAs/AlSb (and similar InAs/GaSb) interfaces, where both cations and anions change, leading to two distinct types of bonding configurations: In-Sb and Al-As. Research has demonstrated that the quality and mobility of the 2DEG are intricately linked to the nature of these interface types. The specific interface configuration, which significantly influences the 2DEG properties, can be altered by the details of the growth process, such as the sequence of deposition (shutter operations) during interface formation [103, 104].

On the other hand, barriers containing only As offer more straightforward growth techniques, which enhance control over crystal quality, such as interface roughness. Moreover, InxGa1-xAs serves as an excellent barrier choice for designs that incorporate near-surface 2DEG systems. By adjusting the In/Ga mole fraction and carefully controlling the thickness of the upper barrier, the 2DEG’s wavefunction is primarily confined within the quantum well and simultaneously also extend to the surface, which is particularly beneficial for research applications such as studying proximity-induced superconductivity.

Doping is another significant consideration of these structures. For the quantum well structures with Sb-involved barriers such as InAs/AlSb and InAs/AlGaSb, the quantum well is relatively deep [105]. As a result, any available donors, such as intentional doping, surface states, and interface-related donors can drain electrons into the well. This is why even undoped structures often show high carrier densities (0.4-1.2 × 1012 cm−2). Modulation-dope attempts were able to raise the carrier density to even higher (3-6 × 1012 cm−2) [106]. However, high carrier density is not always promising for experiments involving the coupling of superconductivity and quantum Hall effects because of the introduction of parallel conduction channels and dominant Coulomb interaction. The structures designed for these experiments normally exclude modulation-doping. Instead, thick top barriers were used for these experiments.

On the other hand, for the quantum well structures that contains no Sb, which are normally grown on InP substrates with graded buffer layers and InGaAs/InAlAs barriers, it was suggested that the deep levels in InAlAs can also donate carriers to the quantum well [107]. Deep 2DEGs (buried 120 nm below the surface) were able to reach a carrier density of 0.4-0.8 × 1012 cm−2 without any intentional doping. However, for those near-surface 2DEGs (about 10-15 nm beneath the surface), studies in Ref. [99] suggested that a Si δ-doping layer in the InAlAs bottom barrier improved the 2DEG mobility. Different from the deep 2DEGs, in near-surface 2DEGs the surface scattering plays an important role. The Si-doping layer was able to pull the 2DEG away from the surface thus reduce surface scattering. Additionally, residual carriers in the Si-doping region were able to enhance screening from defects down below. This effect is similar to that caused by the residual carriers in the GaAs doping well structures, discussed in the previous section.

To summarize this section, the structural design of InAs quantum well structures has considered choice of substrates, intentional design of buffer layers, various materials of quantum well barriers, and doping. As a concluding note for this section, the structural designs of InAs quantum wells that have achieved the highest 2DEG mobilities are summarized below. For quantum wells grown on InP substrates, deep 2DEGs have reached a peak mobility of 1.1 × 106 cm2/Vs at a density of 0.6 × 1012 cm−2 [93], while near-surface 2DEGs have achieved a maximum of 1.0 × 105 cm2/Vs at a density of 0.7 × 1012 cm−2 [99]. In contrast, for quantum wells grown on lattice-matched GaSb substrates, deep 2DEGs have produced a highest mobility of 2.4 × 106 cm2/Vs of 1.2 × 1012 cm−2 [74] (notably here, the structure in Ref. [77] showed a highest mobility of at a density of 2.1 × 106 cm2/Vs at 0.7 × 1012 cm−2, almost half of the density in [74]), and near-surface 2DEGs have recorded up to 6.5 × 105 cm2/Vs at a density of 0.4 × 1012 cm−2 [78]. Figure 7 shows a representative layer structure of a near-surface InAs quantum well grown on an InP substrate. Guided by analysis of \(\mu \propto n^{\alpha} \) relation, almost all studies mentioned above suggested that the uniformly distributed background impurity scattering is the dominant scattering mechanism of the 2DEG.

4 MBE growth technique

Up to this point, this review has explored the structural design of GaAs and InAs heterostructures, examining the underlying physics and material science that drive their development. Beyond these factors, the evolution of Molecular Beam Epitaxy (MBE) techniques has played a pivotal role in enhancing material quality. The subsequent part of this review shifts focus to a material growth perspective, emphasizing crucial aspects such as the maintenance of the vacuum environment, purification of source materials, and the monitoring and precise control of growth conditions. Rather than chronicling the historical development of these techniques, this section delves into the established methodologies currently employed by leading research groups that focus on growth studies of GaAs and InAs heterostructures, showcasing the state-of-the-art in MBE technology for these material systems.

4.1 Vacuum environment

At the heart of MBE’s capability to produce defect-free materials with atomic precision is its reliance on an ultra-high vacuum (UHV) environment. A good UHV environment ensures that the mean free path of the molecules is sufficiently long to prevent collisions between them or with residual gases, which could lead to unintended chemical reactions or the incorporation of impurities, compromising the quality of the grown layers. While the base pressure of the growth chamber is not the universal indicator of vacuum quality, the evolution from a level of 10−10 Torr to a more refined level of 10−12 Torr provides clear evidence of advancements in MBE technology.

A high-quality ultra-high vacuum (UHV) environment results from meticulous attention to detail, starting from the initial lab design. Facility requirements such as maintaining an adequate cleanroom standard and a stable temperature environment are essential. Moreover, research activities that might introduce potential contamination sources, such as hydrocarbon oil and carbon dust, must be strictly regulated and kept away from the MBE system. The MBE system must be specifically customized for particular material systems. For instance, the system reported in Ref. [23] for studying high-mobility GaAs 2DEG structures was equipped with only sources for Ga, As, Al, and small-size silicon and carbon filaments for doping. It is not designed to handle growth tasks involving materials like In or Sb. This selective configuration minimizes the risk of cross-contamination and upholds the integrity of the growth process.

The chamber configuration of an MBE system typically feature a sophisticated design with multiple vacuum levels. Given that the load-lock chamber is frequently exposed to the external environment during regular operation, its vacuum quality is inherently compromised. To mitigate the risk of contaminating the highly sensitive environment of the growth chamber, a “buffer chamber”, also known as a “preparation chamber”, is strategically positioned between the load-lock and growth chambers. This setup includes inter-chamber gate valves that carefully regulate access. The gate valve leading to the growth chamber is only opened once the vacuum quality within the buffer chamber has been thoroughly verified, ensuring that the growth chamber maintains its ultra-high vacuum conditions.

The deployment of advanced pumping systems is a critical component in sustaining a high-quality vacuum environment. Numerous studies have underscored the significance of utilizing state-of-the-art cryogenic pumps. For instance, the review article by Ref. [23] mentions that their MBE system, used for GaAs studies, was equipped with three 3000 liter/sec closed-cycle helium cryopumps. A similar setup was described in Ref. [57], where the MBE system featured four of these cryopumps. Notably—and indeed, deserving of emphasis—this system also included three large nickel-coated copper cold plates, operating at temperatures as low as about 17 K. Researchers documented a substantial improvement in vacuum quality when comparing the performance of certain type of samples grown before and after activating these cold plates, highlighting their effectiveness in enhancing the overall environment for epitaxial growth.

Rigorous maintenance protocols are essential throughout the entire operational lifetime of the MBE system. Initially, the system undergoes a bake-out procedure at approximately 200°C for extended time periods (typically several weeks), which is crucial for minimizing outgassing from the chamber walls and installed components. Once this bake-out is complete, routine maintenance tasks—such as effusion cell installation, material source loading, and any necessary repairs—are conducted under strictly controlled conditions.

Before opening, the chamber is filled with ultra-high-purity inert gases, typically nitrogen or argon. The gas plumbing manifold is meticulously designed and undergoes its own bake-out procedures. During maintenance, a constant flow of inert gas maintains a positive pressure differential relative to the outside environment, effectively isolating the chamber from external contaminants. Instead of exposing the chamber directly to the outside environment, maintenance is performed using glove-bags or glove-boxes. These are pre-filled with inert gas and include all necessary tools and components. This setup undergoes rigorous purging protocols to eliminate potential contaminants, with the purity of the environment sometimes monitored by instruments such as oxygen concentration alarm.

In contemporary MBE system setups, particular attention is increasingly focused on the handling and installation of effusion cells. During the setup process, a new effusion cell typically undergoes extensive pre-baking at temperatures around 1600°C in a specially designed chamber that aims to minimize residual gases. This crucial pre-treatment ensures that the cells are free from impurities that could compromise the growth environment within the main chamber. Once the pre-baking is complete, the effusion cell is carefully removed from the baking chamber, adhering to stringent maintenance protocols akin to those used for the main MBE system. It is then securely transferred to the installation site using airtight containers filled with an inert gas, to the glove-bags/boxes that will be used to open the main chamber for installation.

The vacuum environment is monitored and the maintenance procedures are guided by the residual gas analyzer (RGA). RGAs are sophisticated mass spectrometers designed specifically to detect and measure the types and concentrations of gases present in the vacuum environment [108]. During the setup and operation of MBE systems, RGAs continuously monitor the vacuum quality, enabling operators to make informed decisions about system adjustments or maintenance needs. For instance, the detection of unexpected peaks in the mass spectrum can indicate leaks or outgassing events, prompting immediate corrective actions. An illustrative example of this is detailed in Ref. [56], where Fig. 8 (adopted from Ref. [56]) presents a comparison of typical RGA spectra from a growth chamber before a maintenance event and 24 hours after the maintenance event. The rapid normalization of the spectra and the absence of significant increases in unexpected peaks indicated that there was no need for additional bake-out. The vacuum environment recovered to the pre-vent condition without any additional actions.

A typical comparison of the RGA spectra of the vacuum environment before maintenance (blue) and the RGA spectra of the vacuum environment 24 hours after the maintenance event (red). (adopted from Ref. [56])

4.2 Purification of source materials

A substantial body of research underscored the pivotal role of source material purity in enhancing the quality of semiconductor heterostructures, placing it on par with maintaining an optimal vacuum environment [109–111]. Impurities such as oxides and various unintentionally introduced chemical compounds have been identified as primary contributors to acceptor formation, scattering centers, and crystal defects in GaAs- and InAs-based semiconductor heterostructures.

Source outgassing is now recognized as a fundamental method for material purification, effectively eliminating a wide range of contaminants including organic compounds and other residual gases. Gardner et al. have demonstrated that the quality of source materials can be significantly improved in situ during MBE operations by heating the effusion cell to approximately 200°C above its operating temperature for several hours [56].

Zone refining represents another effective approach to purifying source materials. Implemented before loading the source into the MBE system, this technique involves moving a molten zone along a solid ingot, causing impurities to concentrate in the molten zone and segregate from the solid material. This method is especially beneficial for purifying metals like Ga and In, which have relatively low melting temperatures [112, 113].

Additionally, it has been suggested that conducting long and uninterrupted growth campaigns can also play a crucial role in improving the quality of source materials. Prolonged operations allow for the gradual stabilization and enhancement of the material quality, thereby improving the performance and structural integrity of the heterostructures grown [23].

4.3 Monitoring and control of growth conditions

Precise control over the growth conditions is crucial for the success of MBE techniques. This subsection delves into the key techniques used to monitor and regulate these conditions, including precise measurements of substrate temperatures, detailed analyses of surface conditions and precise control of growth rates.

4.3.1 Substrate temperature measurement

One of the most crucial parameters in the growth conditions of MBE is the substrate temperature. During the MBE growth of semiconductor heterostructures, the optimal temperature for depositing different layers can vary significantly and often requires precise modulation. To contextualize, consider the following examples: for the growth of ‘doping well’ structures, the ideal substrate temperature for depositing GaAs layers and Al0.24Ga0.76As layers is approximately 635°C. However, for the Si doping process, the substrate temperature needs to be reduced to 450°C [56]. This entails rapidly decreasing the substrate temperature to 450°C for doping and then rapidly increasing it back to 635°C for further layer growth. Similarly, in the growth of InAs quantum well structures on InP substrates, the graded buffer layers are typically grown at around 360°C, while the active region requires a substrate temperature of about 480°C [93]. Moreover, for growth processes that involve transitioning from As-based to Sb-based content, precise control over substrate temperature is critical due to differences in sticking coefficients and the sensitivity of interface roughness to temperature fluctuations [77].

However, directly measuring the substrate temperature is challenging. The thermocouples equipped with the substrate heater do not make optimal thermal contact with the substrate, leading to compromised temperature readings. This discrepancy underscores the necessity for advanced temperature monitoring techniques that can provide more accurate and reliable measurements during the MBE process. Most contemporary MBE systems are equipped with an optical pyrometry system, which measures the black body radiation emitted by the substrate through a transparent viewport in the chamber. This radiation is analyzed using Planck’s Law to accurately calculate the substrate temperature [114]. In addition to pyrometry, some MBE systems incorporate a band-edge thermometry system that captures the reflection/absorption spectrum of the substrate. This system measures shifts in the band-edge of the material, providing a precise temperature reading based on the bandgap’s dependency on temperature [115, 116]. Compared to pyrometry, band-edge thermometry offers more precise temperature determinations, especially at lower temperatures critical for processes like the growth of InAlAs graded buffer layers, where temperatures around 360°C are common.

4.3.2 RHEED system and monitoring of surface dynamics

Besides the substrate temperature, another critical factor influencing the growth process is the underlying surface dynamics of the growing film. Controlled by both the substrate temperature and the incoming atomic fluxes, the surface dynamics determines how atoms arrange themselves as they land on the substrate, influencing phenomena such as adatom diffusion, nucleation, and the formation of growth fronts. Understanding and controlling these surface dynamics are essential for optimizing the epitaxial growth process.

Reflection High-Energy Electron Diffraction (RHEED) are crucial for monitoring the surface dynamics, especially by the ability of direction observation of surface reconstructions. The RHEED technique employs a high-energy electron beam directed at a low incident angle toward the semiconductor surface. As these electrons interact with surface atoms, they are diffracted, creating a pattern that is instrumental in analyzing the periodicity of the semiconductor surface and reveals the reconstruction of the surface. Compared with other techniques such as scan tunneling microscopy (STM), RHEED provides an in-situ, real-time analysis of surface reconstruction. A detailed review of the exploration of surface reconstruction phenomena is beyond the scope of this review. However, for a comprehensive study of surface reconstruction in InAs, AlSb, and GaSb, readers are encouraged to consult Ref. [117]. For a broader discussion on semiconductor surface reconstructions, Ref. [118] is also highly recommended. The notations that is used in the following discussion follow the rule in these references.

Understanding and controlling surface reconstructions with the aid of RHEED is pivotal in guiding the MBE growth. For example, during the oxide removal process of a GaAs substrate, the substrate is heated to approximately 650°C and maintained at this temperature for about 15 minutes. Initially, no RHEED pattern is observable due to the thick, non-crystalline oxide layer. However, the emergence of a clear, streaky (2 × 4) reconstruction pattern signals the completion of oxide desorption, effectively timing the process [119]. In contrast, the oxide removal process of a GaSb substrate is often performed using atomic hydrogen flux at a substrate temperature of about 400°C, as described in Ref. [70]. The appearance of a clear (1 × 3) pattern typically indicates complete surface oxide removal.

Additionally, the growth of high-quality GaAs and InAs layers is favored by a (2 × 4) or c(2 × 8) surface reconstruction. Conversely, a lack of arsenic flux or excessive heating of the substrate results in a (4 × 2) reconstruction, which can rapidly degrade the quality of the film being grown. These examples highlight how crucial observations of surface reconstructions by RHEED are in optimizing semiconductor growth processes.

RHEED is also well known as an irreplaceable technique for growth rate monitoring. The principle behind this application revolves around the observation of intensity oscillations in the RHEED patterns (RHEED oscillations) during the epitaxial layer growth. As new atomic layers form on the crystal surface, the conditions for constructive and destructive interference of the diffracted electrons change, leading to periodic fluctuations in the intensity of the diffraction pattern observed on the RHEED screen. Each complete oscillation corresponds to the addition of a single atomic layer to the surface. By measuring the time interval between peaks or in the RHEED signal, the growth rate can be precisely calculated.

It’s important to note that RHEED oscillations may not always be available during real-time growth, especially in scenarios like step-flow or metamorphic growth modes. To accurately determine the optimal effusion cell temperatures, RHEED oscillation experiments are typically conducted in advance using a dedicated RHEED sample. For instance, GaAs and AlAs RHEED oscillations are observable on a GaAs substrate, whereas InAs oscillations require an InAs substrate. Additionally, growth designers must consider variations in lattice constants, as the same quantity of atoms deposited per unit time can result in different growth rates on surfaces with varying lattice dimensions.

To briefly summarize this section, it focused on the crucial role of MBE in the material growth GaAs and InAs heterostructures. It emphasizes the detailed operation procedures required in MBE processes, from maintaining UHV environments to precisely managing the growth conditions. However, this review is not exhaustive; the specific MBE requirements vary significantly depending on the research objectives, laboratory environments, and material systems being developed. Each MBE setup and process is often uniquely tailored to meet the specific needs of the materials and devices under study.

5 Summary and outlook

This review has comprehensively analyzed the advancements in the development of GaAs and InAs heterostructures, with a special emphasis on achieving high material quality and high-mobility 2DEG systems. By reviewing the historical development and current state of these semiconductor heterostructures, we have highlighted how structural design innovations and enhancements in MBE technology have been instrumental in pushing the boundaries of 2DEG mobility and hence supporting the research on condensed matter physics and quantum computing.

While the main focus of this review has been on GaAs and InAs heterostructures, it is important to acknowledge that other material systems, such as InSb and PbTe, are also under intense study for their potential in high-mobility 2DEGs and applications in topological quantum computing.

Looking forward, the field of high-mobility 2DEGs is poised for significant breakthroughs and challenges. Future research will need to address the persistent issues of MBE growth, most importantly, the vacuum environment, material purity and interface quality, while also pushing the boundaries of current fabrication technologies. The efficiency and scalability of the MBE technique as well as a more advanced feedback loop involving structural characterization, device fabrication, and transport measurement is also anticipated in future research. Continuous innovations in structural design could dramatically enhance the understanding of underlying physics and improve the performance of these material systems. As global interest in quantum computing escalates, the strategic development of semiconductor heterostructures will increasingly become a focal point of both academic and industrial research endeavors.

In conclusion, while this review captures a snapshot of the ongoing developments in GaAs and InAs based systems, the dynamic nature of semiconductor research promises new discoveries and technologies that will continue to enhance our understanding and capabilities in this exciting field.

Data availability

Data availability is not applicable to this article as no new data were created or analyzed in this study.

References

Han J, Ferry DK, Newman P (1990) Ultra-submicrometer-gate AlGaAs/GaAs HEMTs. IEEE Electron Device Lett 11(5):209–211

Mishra UK, Parikh P, Wu Y-F (2002) AlGaN/GaN HEMTs-an overview of device operation and applications. Proc IEEE 90(6):1022–1031

Akazaki T, Arai K, Enoki T, Ishii Y (1992) Improved InAlAs/InGaAs HEMT characteristics by inserting an InAs layer into the InGaAs channel. IEEE Electron Device Lett 13(6):325–327

Wang J, Lundstrom M (2003) Ballistic transport in high electron mobility transistors. IEEE Trans Electron Devices 50(7):1604–1609

Mimura T (2005) Development of high electron mobility transistor. Jpn J Appl Phys 44(12R):8263

Alferov ZI (2001) Nobel lecture: the double heterostructure concept and its applications in physics, electronics, and technology. Rev Mod Phys 73(3):767–782

von Klitzing K (1986) The quantized Hall effect. Rev Mod Phys 58(3):519–531

Stormer HL (1999) Nobel lecture: the fractional quantum Hall effect. Rev Mod Phys 71(3):875–899

Haldane FDM, Raghu S (2008) Possible realization of directional optical waveguides in photonic crystals with broken time-reversal symmetry. J Phys Soc Jpn 77(3):031007

Hasan MZ, Kane CL (2010) Colloquium: topological insulators. Rev Mod Phys 82(4):3045–3067

Sarma S, Freedman M, Nayak C (2015) Majorana zero modes and topological quantum computation. npj Quantum Inf 1:15001

Lutchyn RM, Bakkers EPAM, Kouwenhoven LP, Krogstrup P, Marcus CM, Oreg Y (2018) Majorana zero modes in superconductor–semiconductor heterostructures. Nat Rev Mater 3:52–68

Tsui DC, Stormer HL, Gossard AC (1982) Two-dimensional magnetotransport in the extreme quantum limit. Phys Rev Lett 48(22):1559–1562

Das Sarma S, Freedman M, Nayak C (2005) Topologically protected qubits from a possible non-Abelian fractional quantum Hall state. Phys Rev Lett 94(16):166802

Nayak C, Simon SH, Stern A, Freedman M, Das Sarma S (2008) Non-Abelian anyons and topological quantum computation. Rev Mod Phys 80(3):1083–1159

Stern A, Lindner NH (2013) Topological quantum computation—from basic concepts to first experiments. Science 339(6124):1179–1184

Nakamura J, Liang S, Gardner GC, Manfra MJ (2020) Direct observation of anyonic braiding statistics. Nat Phys 16:931–936

Shor PW (1995) Scheme for reducing decoherence in quantum computer memory. Phys Rev A 52(4):R2493–R2496

Aghaee M et al. (2023) InAs-Al hybrid devices passing the topological gap protocol. Phys Rev B 107(24):245423

Kitaev AY (2003) Fault-tolerant quantum computation by anyons. Ann Phys 303(1):2–30

Alicea J, Oreg Y, Refael G, von Oppen F, Fisher MPA (2011) Non-Abelian statistics and topological quantum information processing in 1D wire networks. Nat Phys 7:412–417

Hwang EH, Das Sarma S (2008) Limit to two-dimensional mobility in modulation-doped GaAs quantum structures: how to achieve a mobility of 100 million. Phys Rev B 77:235437

Manfra MJ (2014) Molecular beam epitaxy of ultra-high-quality AlGaAs/GaAs heterostructures: enabling physics in low-dimensional electronic systems. Annu Rev Condens Matter Phys 5:347–373

Das Sarma S, Pan H (2021) Disorder-induced zero-bias peaks in Majorana nanowires. Phys Rev B 103(19):195158

Cho AY (1970) Morphology of epitaxial growth of GaAs by a molecular beam method: the observation of surface structures. J Appl Phys 41(7):2780–2786

Cho AY (1971) GaAs epitaxy by a molecular beam method: observations of surface structure on the (001) face. J Appl Phys 42(5):2074–2081

Cho AY, Reinhart FK (1974) Interface and doping profile characteristics with molecular-beam epitaxy of GaAs: GaAs voltage varactor. J Appl Phys 45(4):1812–1817

Cho AY (1976) Bonding direction and surface-structure orientation on GaAs (001). J Appl Phys 47(7):2841–2843

Cho AY, Arthur JR (1975) Molecular beam epitaxy. Prog Solid State Chem 10(3):157–191

Cho AY, Panish MB, Hayashi I (1970) Proceedings of the international symposium on GaAs and related compounds, Aachen, Germany. Institute of Physics, p 18

Pfeiffer L, West KW (2003) The role of MBE in recent quantum Hall effect physics discoveries. Physica E, Low-Dimens Syst Nanostruct 20(1–2):57–64

Dawson LR (1972) Liquid phase epitaxy. Prog Solid State Chem 7:117–139

Neave JH, Joyce BA (1978) Structure and stoichiometry of {100} GaAs surfaces during molecular beam epitaxy. J Cryst Growth 44(4):387–397

Wood CEC (1981) RED intensity oscillations during MBE of GaAs. Surf Sci 108(2):L441–L443

Wright SL, Jackson TN, Marks RF (1990) Apparent temperature oscillations during molecular-beam epitaxy: a useful interferometric effect. J Vac Sci Technol B 8(2):288–292

Dingle R, Störmer HL, Gossard AC, Wiegmann W (1978) Electron mobilities in modulation-doped semiconductor heterojunction superlattices. Appl Phys Lett 33(7):665–667

Harris JJ, Foxon CT, Barnham KWJ, Lacklison DE, Hewett J, White C (1987) Two-dimensional electron gas structures with mobilities in excess of 3 × 106 cm2 V−1 s−1. J Appl Phys 61(3):1219–1221

English JH, Gossard AC, Störmer HL, Baldwin KW (1987) GaAs structures with electron mobility of 5 × 106 cm2/V s. Appl Phys Lett 50(26):1826–1828

Etienne B, Paris E (1987) Two-dimensional electron gas of very high mobility in planar doped heterostructures. J Phys 48(12):2049–2052

Shayegan M, Goldman VJ, Jiang C, Sajoto T, Santos M (1988) Growth of low-density two-dimensional electron system with very high mobility by molecular beam epitaxy. Appl Phys Lett 52(13):1086–1088

Shayegan M, Goldman VJ, Santos M, Sajoto T, Engel L, Tsui DC (1988) Two-dimensional electron system with extremely low disorder. Appl Phys Lett 53(22):2080–2082

Pfeiffer L, West KW, Stormer HL, Baldwin KW (1989) Electron mobilities exceeding 107 cm2/V s in modulation-doped GaAs. Appl Phys Lett 55(18):1888–1890

Harris JJ (1993) Delta-doping of semiconductors. J Mater Sci, Mater Electron 4:93–105

Chadi DJ, Chang KJ (1989) Energetics of DX-center formation in GaAs and AlxGa1-xAs alloys. Phys Rev B 39(13):10063–10069

Mooney PM (1990) Deep donor levels (DX centers) in III-V semiconductors. J Appl Phys 67(2):R1–R26

Pfeiffer L, Schubert EF, West KW, Magee CW (1991) Si dopant migration and the AlGaAs/GaAs inverted interface. Appl Phys Lett 58(20):2258–2260

Harris JJ, Foxon CT, Lacklison DE, Barnham KWJ (1986) Scattering mechanisms in (Al, Ga)As/GaAs 2DEG structures. Superlattices Microstruct 2(6):563–568

Yang B, Cheng Y, Wang Z, Liang J, Liao Q, Lin L, Zhu Z, Xu B, Li W (1994) Interface roughness scattering in GaAs–AlGaAs modulation-doped heterostructures. Appl Phys Lett 65(25):3329–3331

Tränkle G, Rothfritz H, Müller R, Weimann G (1992) CBE growth of high-quality AlGaAs/GaAs heterostructures for HEMT applications. J Cryst Growth 120(1–4):240–244

Akazaki T, Nitta J, Takayanagi H, Enoki T, Arai K (1996) Highly confined two-dimensional electron gas in an In0.52Al0.48As/In0.52Ga0.47As modulation-doped structure with a strained InAs quantum well. J Electron Mater 25(5):745–748

Pfeiffer LN, West KW, Eisenstein JP, Baldwin KW, Gammel P (1992) Multiquantum well structure with an average electron mobility of 4.0 × 106 cm2/V s. Appl Phys Lett 61(10):1211–1212

Friedland K-J, Hey R, Kostial H, Klann R, Ploog K (1996) New concept for the reduction of impurity scattering in remotely doped GaAs quantum wells. Phys Rev Lett 77(23):4616–4619

Holtz M, Cingolani R, Reimann K, Muralidharan R, Syassen K, Ploog K (1990) Electronic structure of GaAs/AlAs symmetric superlattices: a high-pressure study near the type-I–type-II crossover. Phys Rev B 41(6):3641–3646

Umansky V, Heiblum M, Levinson Y, Smet J, Nübler J, Dolev M (2009) MBE growth of ultra-low disorder 2DEG with mobility exceeding 35 × 106 cm2/V s. J Cryst Growth 311(7):1658–1661

Eisenstein JP, Cooper KB, Pfeiffer LN, West KW (2002) Insulating and fractional quantum Hall states in the first excited Landau level. Phys Rev Lett 88(7):076801

Gardner GC, Fallahi S, Watson JD, Manfra MJ (2016) Modified MBE hardware and techniques and role of gallium purity for attainment of two-dimensional electron gas mobility > 35 × 106 cm2/V s in AlGaAs/GaAs quantum wells grown by MBE. J Cryst Growth 441:71–77

Chung YJ, Villegas Rosales KA, Baldwin KW, Madathil PT, West KW, Shayegan M, Pfeiffer LN (2021) Ultra-high-quality two-dimensional electron systems. Nat Mater 20:632–637

Chung YJ, Gupta A, Baldwin KW, West KW, Shayegan M, Pfeiffer LN (2022) Understanding limits to mobility in ultrahigh-mobility GaAs two-dimensional electron systems: 100 million cm2/Vs and beyond. Phys Rev B 106(7):075134

Ando T (1982) Self-consistent results for a GaAs/AlxGa1-xAs heterojunction. II. Low temperature mobility. J Phys Soc Jpn 51(12):3900–3907

Lee HJ, Look DC (1983) Hole transport in pure and doped GaAs. J Appl Phys 54(8):4446–4452

Walukiewicz W, Ruda HE, Lagowski J, Gatos HC (1984) Electron mobility limits in a two-dimensional electron gas: GaAs-GaAlAs heterostructures. Phys Rev B 29(10):4818

Gold A (1989) Mobility of the two-dimensional electron gas in AlGaAs/GaAs heterostructures at low electron densities. Appl Phys Lett 54(21):2100–2102

Buks E, Heiblum M, Shtrikman H (1994) Correlated charged donors and strong mobility enhancement in a two-dimensional electron gas. Phys Rev B 49(20):14790

Saku T, Horikoshi Y, Tokura Y (1996) Limit of electron mobility in AlGaAs/GaAs modulation-doped heterostructures. Jpn J Appl Phys 35(1R):34–40

Umansky V, de-Picciotto R, Heiblum M (1997) Extremely high-mobility two-dimensional electron gas: evaluation of scattering mechanisms. Appl Phys Lett 71(5):683–685

Das Sarma S, Hwang EH (2014) Mobility versus quality in two-dimensional semiconductor structures. Phys Rev B 90(3):035425

Schaffer WJ, Lind MD, Kowalczyk SP, Grant RW (1983) Nucleation and strain relaxation at the InAs/GaAs(100) heterojunction. J Vac Sci Technol B 1(3):688–695

Sasaki A (1996) Initial growth layers and critical thickness of InAs heteroepitaxy on GaAs substrates. J Cryst Growth 160(1–2):27–35

MIT OpenCourseWare (2009) Energy Gap and Lattice Constants. Flickr. https://www.flickr.com/photos/mitopencourseware/3323411096

Weiss E, Klin O, Grossman S, Greenberg S, Klipstein PC, Akhvlediani R, Tessler R, Edrei R, Hoffman A (2007) Hydrogen and thermal deoxidations of InSb and GaSb substrates for molecular beam epitaxial growth. J Vac Sci Technol A 25(4):736–745

Chang LL, Esaki L (1980) Electronic properties of InAs–GaSb superlattices. Surf Sci 98(1–3):70–89

Chang CA, Mendez EE, Chang LL, Esaki L (1984) Quantum wells of InAs between AlSb. Surf Sci 142(1–3):598–602

Nguyen B-M, Yi W, Noah R, Thorp J, Sokolich M (2015) High mobility back-gated InAs/GaSb double quantum well grown on GaSb substrate. Appl Phys Lett 106(3):032107

Tschirky T, Mueller S, Lehner CA, Fält S, Ihn T, Ensslin K, Wegscheider W (2017) Scattering mechanisms of highest-mobility InAs/AlxGa1-xSb quantum wells. Phys Rev B 95(11):115304

Shojaei B, O’Malley PJJ, Shabani J, Roushan P, Schultz BD, Lutchyn RM, Nayak C, Martinis JM, Palmstrøm CJ (2016) Demonstration of gate control of spin splitting in a high-mobility InAs/AlSb two-dimensional electron gas. Phys Rev B 93(7):075302

Shojaei B, Drachmann ACC, Pendharkar M, Pennachio DJ, Echlin MP, Callahan PG, Kraemer S, Pollock TM, Marcus CM, Palmstrøm CJ (2016) Limits to mobility in InAs quantum wells with nearly lattice-matched barriers. Phys Rev B 94(24):245306

Thomas C, Hatke AT, Tuaz A, Kallaher R, Wu T, Wang T, Diaz RE, Gardner GC, Capano MA, Manfra MJ (2018) High-mobility InAs 2DEGs on GaSb substrates: a platform for mesoscopic quantum transport. Phys Rev Mater 2(10):104602

Lee JS, Shojaei B, Pendharkar M, Feldman M, Mukherjee K, Palmstrøm CJ (2019) Contribution of top barrier materials to high mobility in near-surface InAs quantum wells grown on GaSb(001). Phys Rev Mater 3(1):014603

Takano Y, Kobayashi K, Iwahori H, Umezawa M, Shirakata S, Fuke S (2005) Threading dislocations and phase separation in InGaAs layers on GaAs substrates grown by low-temperature metalorganic vapor phase epitaxy. Jpn J Appl Phys 44(9R):6474–6480

Nitta J, Akazaki T, Takayanagi H, Arai K (1992) Transport properties in an InAs-inserted-channel In0.52Al0.48As/In0.53Ga0.47As heterostructure coupled superconducting junction. Phys Rev B 46(21):14286

Akazaki T, Takayanagi H, Nitta J, Enoki T (1996) A Josephson field effect transistor using an InAs-inserted-channel In0.52Al0.48As/In0.53Ga0.47As inverted modulation-doped structure. Appl Phys Lett 68(3):418–420

Dunstan DJ (1997) Strain and strain relaxation in semiconductors. J Mater Sci, Mater Electron 8:337–375

Nguyen C, Brar B, Bolognesi CR, Pekarik JJ, Kroemer H, English JH (1993) Growth of InAs-AlSb quantum wells having both high mobilities and high concentrations. J Electron Mater 22(2):255–258

Blank H-R, Mathis S, Hall E, Bhargava S, Behres A, Heuken M, Kroemer H, Narayanamurti V (1998) Al(As, Sb) heterobarriers on InAs: growth, structural properties and electrical transport. J Cryst Growth 187(1):18–28

Sadofyev YG, Ramamoorthy A, Naser B, Bird JP, Johnson SR, Zhang Y-H (2002) Large g-factor enhancement in high-mobility InAs/AlSb quantum wells. Appl Phys Lett 81(10):1833–1835

Joo KS, Chun SH, Lim JY, Song JD, Chang JY (2008) Metamorphic growth of InAlAs/InGaAs MQW and InAs HEMT structures on GaAs. Physica E, Low-Dimens Syst Nanostruct 40(9):2874–2878

Bulsara MT, Leitz C, Fitzgerald EA (1998) Relaxed InxGa1-xAs graded buffers grown with organometallic vapor phase epitaxy on GaAs. Appl Phys Lett 72(13):1608–1610

Cordier Y, Lorenzini P, Chauveau J-M, Ferré D, Androussi Y, DiPersio J, Vignaud D, Codron J-L (2003) Influence of MBE growth conditions on the quality of InAlAs/InGaAs metamorphic HEMTs on GaAs. J Cryst Growth 251(1–4):822–826

Löhr S, Heyn C, Hansen W (2004) Nonplanar two-dimensional electron gases in InAs heterostructures on GaAs. Appl Phys Lett 84(4):550–552

Wallart X, Lastennet J, Vignaud D, Mollot F (2005) Performances and limitations of metamorphic heterostructures on InP for high mobility devices. Appl Phys Lett 87(4):043504

Lin Y, Carlin JA, Arehart AR, Carlin AM, Ringel SA (2007) High-mobility two-dimensional electron gas in InAlAs/InAs heterostructures grown on virtual InAs substrates by molecular-beam epitaxy. Appl Phys Lett 90(1):012115

Shabani J, McFadden AP, Shojaei B, Palmstrøm CJ (2014) Gating of high-mobility InAs metamorphic heterostructures. Appl Phys Lett 105(26):262105

Hatke AT, Wang T, Thomas C, Gardner GC, Manfra MJ (2017) Mobility in excess of 106 cm2/V s in InAs quantum wells grown on lattice mismatched InP substrates. Appl Phys Lett 111(14):142106

Sacedón A, González-Sanz F, Calleja E, Muñoz E, Molina SI, Pacheco FJ, Araújo D, García R, Lourenço M, Yang Z, Kidd P, Dunstan D (1995) Design of InGaAs linear graded buffer structures. Appl Phys Lett 66(25):3334–3336

Gu Y, Zhang YG, Wang K, Fang X, Li C, Cao YY, Li AZ, Li YY (2011) InP-based InAs/InGaAs quantum wells with type-I emission beyond 3μm. Appl Phys Lett 99(8):081914

Nichele F, Drachmann ACC, Whiticar AM, O’Farrell ECT, Suominen HJ, Fornieri A, Wang T, Gardner GC, Thomas C, Hatke AT, Krogstrup P, Manfra MJ, Flensberg K, Marcus CM (2017) Scaling of Majorana zero-bias conductance peaks. Phys Rev Lett 119(13):136803

Fornieri A, Whiticar AM, Setiawan F, Portolés E, Drachmann ACC, Keselman A, Gronin S, Thomas C, Wang T, Kallaher R, Gardner GC, Berg E, Manfra MJ, Stern A, Marcus CM, Nichele F (2019) Evidence of topological superconductivity in planar Josephson junctions. Nature 569(7754):89–92

Baumgartner C, Fuchs L, Costa A, Reinhardt S, Gronin S, Gardner GC, Lindemann T, Manfra MJ, Faria Junior PE, Kochan D, Fabian J, Paradiso N, Strunk C (2022) Supercurrent rectification and magnetochiral effects in symmetric Josephson junctions. Nat Nanotechnol 17(1):39–44

Zhang T, Lindemann T, Gardner GC, Gronin S, Wu T, Manfra MJ (2023) Mobility exceeding 100,000 cm2/V s in modulation-doped shallow InAs quantum wells coupled to epitaxial aluminum. Phys Rev Mater 7(5):056201

Luo J, Munekata H, Fang FF, Stiles PJ (1990) Effects of inversion asymmetry on electron energy band structures in GaSb/InAs/GaSb quantum wells. Phys Rev B 41(11):7685–7693

Tuttle G, Kroemer H, English JH (1989) Electron concentrations and mobilities in AlSb/InAs/AlSb quantum wells. J Appl Phys 65(12):5239–5242

Yoh K, Moriuchi T, Inoue M (1990) An InAs channel heterojunction field-effect transistor with high transconductance. IEEE Electron Device Lett 11(11):526–528

Spitzer J, Fuchs HD, Etchegoin P, Ilg M, Cardona M, Brar B, Kroemer H (1993) Quality of AlAs-like and InSb-like interfaces in InAs/AlSb superlattices: an optical study. Appl Phys Lett 62(19):2274–2276

Steinshnider J, Harper J, Weimer M, Lin C-H, Pei SS, Chow DH (2000) Origin of antimony segregation in GaInSb/InAs strained-layer superlattices. Phys Rev Lett 85(21):4562–4565

Kroemer H (2004) The 6.1 Å family (InAs, GaSb, AlSb) and its heterostructures: a selective review. Physica E, Low-Dimens Syst Nanostruct 20(3–4):196–203

Bennett BR, Yang MJ, Shanabrook BV, Boos JB, Park D (1998) Modulation doping of InAs/AlSb quantum wells using remote InAs donor layers. Appl Phys Lett 72(10):1193–1195

Capotondi F, Biasiol G, Vobornik I, Sorba L, Giazotto F, Cavallini A, Fraboni B (2004) Two-dimensional electron gas formation in undoped In0.75Ga0.25As/In0.75Al0.25As quantum wells. J Vac Sci Technol B 22(2):702–706

Lichtman D (1990) Residual gas analysis: past, present, and future. J Vac Sci Technol A 8(3):2810–2813

Schubert EF (1995) Doping in III-V semiconductors. Cambridge University Press, Cambridge

Chand N, Miller RC, Sergent AM, Sputz SK, Lang DV (1988) Effect of arsenic source on the growth of high-purity GaAs by molecular beam epitaxy. Appl Phys Lett 52(21):1721–1723

Schmult S, Taylor S, Dietsche W (2009) Gallium beam analysis and implications for the growth of ultra-high-mobility GaAs/AlGaAs heterostructures. J Cryst Growth 311(7):1655–1657

Shiraki Y, Mishima T, Morioka M (1987) Low temperature MBE growth of high quality AlGaAs. J Cryst Growth 81(1–4):164–168

Mani VN (2006) Ultra high purity gallium and indium for emerging III-V epitaxial nanoelectronics materials technologies: an overview. Mater Sci Res India 3(2a):215–230

Sotnikova GY, Gavrilov GA, Sukhanov VL, Chernykh DF, Aleksandrov SE, Kapralov AA, Alekseev AN, Shkurko AP (2007) A universal pyrometer for molecular-beam epitaxy setups. Instrum Exp Tech 50(4):572–577

Johnson S, Kuo C-H, Boonzaayer M, Braun W, Koelle U, Zhang Y-H, Roth J (1998) In situ temperature control of molecular beam epitaxy growth using band-edge thermometry. J Vac Sci Technol B 16(3):1502–1506

Farrer I, Harris JJ, Thomson R, Barlett D, Taylor CA, Ritchie DA (2007) Substrate temperature measurement using a commercial band-edge detection system. J Cryst Growth 301–302:88–92

Bracker AS, Yang MJ, Bennett BR, Culbertson JC, Moore WJ (2000) Surface reconstruction phase diagrams for InAs, AlSb, and GaSb. J Cryst Growth 220(4):384–392

Duke CB (1996) Semiconductor surface reconstruction: the structural chemistry of two-dimensional surface compounds. Chem Rev 96(4):1237–1260

Asaoka Y (2003) Desorption process of GaAs surface native oxide controlled by direct Ga-beam irradiation. J Cryst Growth 251(1–4):40–45

Funding

This work is supported by National Natural Science Foundation of China (92065206) and the Innovation Program for Quantum Science and Technology (2021ZD0302400).

Author information

Authors and Affiliations

Contributions

TW drafted the manuscript. KH and HS reviewed, edited, and approved the final version of the manuscript. All authors confirmed that the review has not been published before. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

Ke He is a member of the editorial board of Quantum Frontiers, and was not involved in the editorial review or the decision to publish this article. All authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, T., Song, H. & He, K. Structural design and molecular beam epitaxy growth of GaAs and InAs heterostructures for high mobility two-dimensional electron gas. Quantum Front 3, 13 (2024). https://doi.org/10.1007/s44214-024-00061-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44214-024-00061-5