Abstract

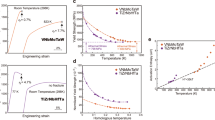

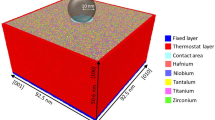

Ductile failure is studied in a bcc HfNbTaZr High-Entropy Alloy (HEA) with a pre-existing void. Using molecular dynamics simulations of uniaxial tensile tests, we explore the effect of void radius on the elastic modulus and yield stress. The elastic modulus scales with porosity as in closed-cell foams. The critical stress for dislocation nucleation as a function of the void radius is very well described by a model designed after pure bcc metals, taking into account a larger core radius for the HEA. Twinning takes place as a complementary deformation mechanism, and some detwinning occurs at large strain. No solid–solid phase transitions are identified. The concurrent effects of element size mismatch and plasticity lead to significant lattice disorder. By comparing our HEA results to pure tantalum simulations, we show that the critical stress for dislocation nucleation and the resulting dislocation densities are much lower than for pure Ta, as expected from lower energy barriers due to chemical complexity.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

B. Cantor, I. Chang, P. Knight, A. Vincent, Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 375, 213–218 (2004). https://doi.org/10.1016/j.msea.2003.10.257

J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.-T. Shun, C.-H. Tsau, S.-Y. Chang, Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv. Eng. Mater. 6, 299–303 (2004). https://doi.org/10.1002/adem.200300567

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, Z.P. Lu, Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 61, 1–93 (2014). https://doi.org/10.1016/j.actamat.2016.08.081

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George, R.O. Ritchie, A fracture-resistant high-entropy alloy for cryogenic applications. Science 345, 1153–1158 (2014). https://doi.org/10.1126/science.1254581

Z. Li, S. Zhao, R.O. Ritchie, M.A. Meyers, Mechanical properties of high-entropy alloys with emphasis on face-centered cubic alloys. Prog. Mater Sci. 102, 296–345 (2019). https://doi.org/10.1016/j.pmatsci.2018.12.003

D.B. Miracle, O.N. Senkov, A critical review of high entropy alloys and related concepts. Acta Mater. 122, 448–511 (2017). https://doi.org/10.1016/j.actamat.2016.08.081

O.N. Senkov, G. Wilks, J. Scott, D.B. Miracle, Mechanical properties of nb25mo25ta25w25 and v20nb20mo20ta20w20 refractory high entropy alloys. Intermetallics 19, 698–706 (2011). https://doi.org/10.1016/j.intermet.2011.01.004

M. Kawamura, M. Asakura, N.L. Okamoto, K. Kishida, H. Inui, E.P. George, Plastic deformation of single crystals of the equiatomic cr- mn- fe- co- ni high-entropy alloy in tension and compression from 10 k to 1273 k. Acta Mater. 203, 116454 (2021). https://doi.org/10.1016/j.actamat.2020.10.073

J.-W. Yeh, Physical metallurgy of high-entropy alloys. Jom 67, 2254–2261 (2015). https://doi.org/10.1007/s11837-015-1583-5

E.J. Pickering, A.W. Carruthers, P.J. Barron, S.C. Middleburgh, D.E. Armstrong, A.S. Gandy, High-entropy alloys for advanced nuclear applications. Entropy 23, 98 (2021). https://doi.org/10.3390/e23010098

O. Deluigi, R. Pasianot, F. Valencia, A. Caro, D. Farkas, E. Bringa, Simulations of primary damage in a high entropy alloy: probing enhanced radiation resistance. Acta Mater. 213, 116951 (2021). https://doi.org/10.1016/j.actamat.2021.116951

S. Zhao, Y. Xiong, S. Ma, J. Zhang, B. Xu, J.-J. Kai, Defect accumulation and evolution in refractory multi-principal element alloys. Acta Mater. 219, 117233 (2021). https://doi.org/10.1016/j.actamat.2021.117233

H. Son, S. Nam, H. Choi, Development of porous high-entropy alloys by mechanical alloying and chemical de-alloying. Powder Metall. 64, 211–218 (2021). https://doi.org/10.1080/00325899.2021.1901399

M.C. Gao, D.B. Miracle, D. Maurice, X. Yan, Y. Zhang, J.A. Hawk, High-entropy functional materials. J. Mater. Res. 33, 3138–3155 (2018). https://doi.org/10.1557/jmr.2018.323

E.P. George, D. Raabe, R.O. Ritchie, High-entropy alloys. Nat. Rev. Mater. 4, 515–534 (2019). https://doi.org/10.1038/s41578-019-0121-4

W. Steurer, Single-phase high-entropy alloys–a critical update. Mater. Charact. 162, 110179 (2020). https://doi.org/10.1016/j.matchar.2020.110179

B. Gao, Q. Xiang, T. Guo, X. Guo, S. Tang, X.X. Huang, In situ tem investigation on void coalescence in metallic materials. Mater. Sci. Eng. A 734, 260–268 (2018). https://doi.org/10.1016/j.msea.2018.07.064

O.N. Senkov, D.B. Miracle, K.J. Chaput, J.-P. Couzinie, Development and exploration of refractory high entropy alloys—a review. J. Mater. Res. 33, 3092–3128 (2018). https://doi.org/10.1557/jmr.2018.153

E.P. George, W. Curtin, C.C. Tasan, High entropy alloys: a focused review of mechanical properties and deformation mechanisms. Acta Mater. 188, 435–474 (2020). https://doi.org/10.1016/j.actamat.2019.12.015

S. Mishra, S. Maiti, B.S. Dwadasi, B. Rai, Realistic microstructure evolution of complex Ta-Nb-Hf-Zr high-entropy alloys by simulation techniques. Sci. Rep. 9, 1–11 (2019). https://doi.org/10.1038/s41598-019-52170-0

C. Lee, F. Maresca, R. Feng, Y. Chou, T. Ungar, M. Widom, K. An, J.D. Poplawsky, Y.-C. Chou, P.K. Liaw et al., Strength can be controlled by edge dislocations in refractory high-entropy alloys. Nat. Commun. 12, 1–8 (2021). https://doi.org/10.1038/s41467-021-25807-w

S. Peng, K. Jin, X. Yi, Z. Dong, X. Guo, Y. Liu, Y. Cheng, N. Jia, H. Duan, J. Xue, Mechanical behavior of the HfNbZrTi high entropy alloy after ion irradiation based on micropillar compression tests. J. Alloy Compd. 892, 162043 (2022). https://doi.org/10.1016/j.jallcom.2021.162043

Y. Bu, Y. Wu, Z. Lei, X. Yuan, H. Wu, X. Feng, J. Liu, J. Ding, Y. Lu, H. Wang, Z. Lu, W. Yang, Local chemical fluctuation mediated ductility in body-centered-cubic high-entropy alloys. Mater. Today 46, 28–34 (2021). https://doi.org/10.1016/j.mattod.2021.02.022

F. Liu, P.K. Liaw, Y. Zhang, Recent progress with bcc-structured high-entropy alloys. Metals 12, 501 (2022). https://doi.org/10.3390/met12030501

M. Widom, Modeling the structure and thermodynamics of high-entropy alloys. J. Mater. Res. 33(19), 2881–2898 (2018). https://doi.org/10.1557/jmr.2018.222

Z.H. Aitken, V. Sorkin, Y.-W. Zhang, Atomistic modeling of nanoscale plasticity in highentropy alloys. J. Mater. Res. 34, 1509–1532 (2019). https://doi.org/10.1557/jmr.2019.50

J. Li, Q. Fang, P.K. Liaw, Microstructures and properties of high-entropy materials: modeling, simulation, and experiments. Adv. Eng. Mater. 23, 2001044 (2021). https://doi.org/10.1002/adem.202001044

D. Farkas, Grain boundary structure in high-entropy alloys. J. Mater. Sci. 55, 9173–9183 (2020). https://doi.org/10.1007/s10853-020-04387-y

D. Farkas, A. Caro, Model interatomic potentials and lattice strain in a high-entropy alloy. J. Mater. Res. 33, 3218–3225 (2018). https://doi.org/10.1557/jmr.2018.245

R. Pasianot, D. Farkas, Atomistic modeling of dislocations in a random quinary high entropy alloy. Comput. Mater. Sci. 173, 109366 (2020). https://doi.org/10.1016/j.commatsci.2019.109366

C.J. Ruestes, D. Farkas, Deformation response of high entropy alloy nanowires. J. Mater. Sci. 56, 16447–16462 (2021). https://doi.org/10.1016/j.commatsci.2022.111218

D. Farkas, Deformation behavior of a model high entropy alloy from atomistic simulations. Mater. Sci. Eng. A 812, 141124 (2021). https://doi.org/10.1016/j.msea.2021.141124

C.J. Ruestes, D. Farkas, Dislocation emission and propagation under a nano-indenter in a model high entropy alloy. Comput. Mater. Sci. 205, 111218 (2022). https://doi.org/10.1016/j.commatsci.2022.111218

Y. Cui, Z. Chen, Y. Ju, Fracture of void-embedded high-entropy-alloy films: a comprehensive atomistic study. Materialia 12, 100790 (2020). https://doi.org/10.1016/j.mtla.2020.100790

Y. Cui, Y. Toku, Y. Kimura, Y. Ju, High-strain-rate void growth in high entropy alloys: suppressed dislocation emission = suppressed void growth. Scripta Mater. 185, 12–18 (2020). https://doi.org/10.1016/j.scriptamat.2020.03.056

Y. Cui, Z. Chen, S. Gu, W. Yang, Y. Ju, Investigating size dependence in nanovoid embedded high-entropy-alloy films under biaxial tension. Arch. Appl. Mech. (2022). https://doi.org/10.1007/s00419-021-02100-2

S.K. Singh, A. Parashar, Atomistic simulations to study crack tip behaviour in multielemental alloys. Eng. Fract. Mech. 243, 107536 (2021). https://doi.org/10.1016/j.engfracmech.2021.107536

Z. Zhang, M.M. Mao, J. Wang, B. Gludovatz, Z. Zhang, S.X. Mao, E.P. George, Q. Yu, R.O. Ritchie, Nanoscale origins of the damage tolerance of the high-entropy alloy CrMnFeCoNi. Nat. Commun. 6, 1–6 (2015). https://doi.org/10.1038/ncomms10143

X. Huang, L. Liu, X. Duan, W. Liao, J. Huang, H. Sun, C. Yu, Atomistic simulation of chemical short-range order in hfnbtazr high entropy alloy based on a newly-developed interatomic potential. Mater. Des. 202, 109560 (2021). https://doi.org/10.1016/j.matdes.2021.109560

S. Plimpton, Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995). https://doi.org/10.1006/jcph.1995.1039

M.S. Daw, M.I. Baskes, Embedded-atom method: derivation and application to impurities, surfaces, and other defects in metals. Phys. Rev. B 29, 6443 (1984). https://doi.org/10.1103/PhysRevB.29.6443

S. Maiti, W. Steurer, Structural-disorder and its effect on mechanical properties in single-phase TaNbHfZr high-entropy alloy. Acta Mater. 106, 87–97 (2016). https://doi.org/10.1016/j.actamat.2016.01.018

D. Thurmer, S. Zhao, O.R. Deluigi, C. Stan, I.A. Alhafez, H.M. Urbassek, M.A. Meyers, E.M. Bringa, N. Gunkelmann, Exceptionally high spallation strength for a high-entropy alloy demonstrated by experiments and simulations. J. Alloy Compd. 895, 162567 (2022). https://doi.org/10.1016/j.jallcom.2021.162567

Y. Tang, E.M. Bringa, M.A. Meyers, Ductile tensile failure in metals through initiation and growth of nanosized voids. Acta Mater. 60, 4856–4865 (2012). https://doi.org/10.1016/j.actamat.2012.05.030

A. Stukowski, Visualization and analysis of atomistic simulation data with ovito–the open visualization tool. Modell. Simul. Mater. Sci. Eng. 18, 015012 (2009). https://doi.org/10.1088/0965-0393/18/1/015012

P.M. Larsen, S. Schmidt, J. Schiøtz, Robust structural identification via polyhedral template matching. Modell. Simul. Mater. Sci. Eng. 24, 055007 (2016). https://doi.org/10.1088/0965-0393/24/5/055007

A. Stukowski, K. Albe, Dislocation detection algorithm for atomistic simulations. Modell. Simul. Mater. Sci. Eng. 18, 025016 (2010). https://doi.org/10.1088/0965-0393/18/2/025016

A. Stukowski, Computational analysis methods in atomistic modeling of crystals. Jom 66, 399–407 (2014). https://doi.org/10.1007/s11837-013-0827-5

F. Shimizu, S. Ogata, J. Li, Theory of shear banding in metallic glasses and molecular dynamics calculations. Mater. Trans. 48, 2923–2927 (2007). https://doi.org/10.2320/matertrans.MJ200769

J.A. Martinez, D.E. Yilmaz, T. Liang, S.B. Sinnott, S.R. Phillpot, Fitting empirical potentials: challenges and methodologies. Curr. Opin. Solid State Mater. Sci. 17, 263–270 (2013). https://doi.org/10.1016/j.cossms.2013.09.001

S. Mishra, S. Maiti, B. Rai, Computational property predictions of Ta–Nb–Hf–Zr highentropy alloys. Sci. Rep. 11, 1–12 (2021). https://doi.org/10.1038/s41598-021-84260-3

F. Mouhat, F.-X. Coudert, Necessary and sufficient elastic stability conditions in various crystal systems. Phys. Rev. B 90, 224104 (2014). https://doi.org/10.1103/PhysRevB.90.224104

M.A. Meyers, K.K. Chawla, Mechanical Behavior of Materials (Cambridge University Press, Cambridge, 2008)

G. Ziegenhain, H.M. Urbassek, A. Hartmaier, Influence of crystal anisotropy on elastic deformation and onset of plasticity in nanoindentation: a simulational study. J. Appl. Phys. 107, 061807 (2010). https://doi.org/10.1063/1.3340523

A. Reuss, Berücksichtigung der elastischen formänderung in der plastizitätstheorie. J. Appl. Math. Mech. 10, 266–274 (1930). https://doi.org/10.1002/zamm.19300100308

W. Voigt, Lehrbuch der kristallphysik:(mit ausschluss der kristalloptik), vol. 34, BG Teubner, 1910.

C.J. Ruestes, A. Stukowski, Y. Tang, D. Tramontina, P. Erhart, B. Remington, H. Urbassek, M.A. Meyers, E.M. Bringa, Atomistic simulation of tantalum nanoindentation: effects of indenter diameter, penetration velocity, and interatomic potentials on defect mechanisms and evolution. Mater. Sci. Eng. A 613, 390–403 (2014). https://doi.org/10.1016/j.msea.2014.07.001

H. Sheng, M. Kramer, A. Cadien, T. Fujita, M. Chen, Highly optimized embedded-atommethod potentials for fourteen fcc metals. Phys. Rev. B 83, 134118 (2011). https://doi.org/10.1103/PhysRevB.83.134118

S. Rao, C. Varvenne, C. Woodward, T. Parthasarathy, D. Miracle, O. Senkov, W. Curtin, Atomistic simulations of dislocations in a model bcc multicomponent concentrated solid solution alloy. Acta Mater. 125, 311–320 (2017). https://doi.org/10.1016/j.actamat.2016.12.011

Q. He, Y. Yang, On lattice distortion in high entropy alloys. Front. Mater. 5, 42 (2018). https://doi.org/10.3389/fmats.2018.00042

O. Senkov, D. Miracle, Effect of the atomic size distribution on glass forming ability of amorphous metallic alloys. Mater. Res. Bull. 36, 2183–2198 (2001). https://doi.org/10.1016/S0025-5408(01)00715-2

H. Song, F. Tian, Q.-M. Hu, L. Vitos, Y. Wang, J. Shen, N. Chen, Local lattice distortion in high-entropy alloys. Phys. Rev. Mater. 1, 023404 (2017). https://doi.org/10.1103/PhysRevMaterials.1.023404

Y. Tang, E.M. Bringa, B.A. Remington, M.A. Meyers, Growth and collapse of nanovoids in tantalum monocrystals. Acta Mater. 59, 1354–1372 (2011). https://doi.org/10.1016/j.actamat.2010.11.001

M. Ashby, A. Evans, N. Fleck, L. Gibson, J. Hutchinson, H. Wadley, F. Delale, Metal foams: a design guide. Appl. Mech. Rev. 54(6), B105–B106 (2000)

Y.-J. Hu, A. Sundara, S. Ogata, L. Qi, Screening of generalized stacking fault energies, surface energies and intrinsic ductile potency of refractory multicomponent alloys. Acta Mater. 210, 116800 (2021). https://doi.org/10.1016/j.actamat.2021.116800

D. Tramontina, C. Ruestes, Y. Tang, E. Bringa, Orientation-dependent response of defective tantalum single crystals. Comput. Mater. Sci. 90, 82–88 (2014). https://doi.org/10.1016/j.commatsci.2014.03.069

T. Tang, S. Kim, M. Horstemeyer, Molecular dynamics simulations of void growth and coalescence in single crystal magnesium. Acta Mater. 58, 4742–4759 (2010). https://doi.org/10.1016/j.actamat.2010.05.011

V.A. Lubarda, M. Schneidera, D. Kalantar, B. Remington, M. Meyers, Void growth by dislocation emission. Acta Mater. 52, 1397 (2004). https://doi.org/10.1016/j.actamat.2003.11.022

L. Zhao, H. Zong, X. Ding, T. Lookman, Anomalous dislocation core structure in shock compressed bcc high-entropy alloys. Acta Mater. 209, 116801 (2021). https://doi.org/10.1016/j.actamat.2021.116801

Y. Xiao, R. Kozak, M. Hache, S. Walter, R. Spolenak, J. Wheeler, Y. Zou, Microcompression studies of face-centered cubic and body-centered cubic high-entropy alloys: size-dependent strength, strain rate sensitivity, and activation volumes. Mater. Sci. Eng. A 90, 139429 (2020). https://doi.org/10.1016/j.msea.2020.139429

S.-H. Joo, J. Bae, W.-Y. Park, Y. Shimada, T. Wada, H. Kim, A. Takeuchi, T. Konno, H. Kato, I. Okulov, Beating thermal coarsening in nanoporous materials via high-entropy design. Adv. Mater. 32, 1906160 (2020). https://doi.org/10.1002/adma.201906160

H. Van Swygenhoven, P.M. Derlet, A.G. Frøseth, Stacking fault energies and slip in nanocrystalline metals. Nat. Mater. 3, 399–403 (2004). https://doi.org/10.1038/nmat1136

M. Beyramali Kivy, M. Asle Zaeem, Generalized stacking fault energies, ductilities, and twinnabilities of CoCrFeNi-based face-centered cubic high entropy alloys. Scripta Mater. 139, 83–86 (2017). https://doi.org/10.1016/j.scriptamat.2017.06.014

N. Zhang, K. Gan, Z. Li, Atomistic insights on the deformation mechanisms of Cox(CrNi)100–x multicomponent alloys: the effect of Co content. Comput. Mater. Sci. 211, 111559 (2022). https://doi.org/10.1016/j.commatsci.2022.111559

S. Qiu, X.C. Zhang, J. Zhou, S. Cao, H. Yu, Q.M. Hu, Z. Sun, Influence of lattice distortion on stacking fault energies of CoCrFeNi and Al-CoCrFeNi high entropy alloys. J. Alloy Compd. 846, 156321 (2020). https://doi.org/10.1016/j.jallcom.2020.156321

C.J. Ruestes, E.M. Bringa, A. Stukowski, J.R. Nieva, Y. Tang, M. Meyers, Plastic deformation of a porous bcc metal containing nanometer sized voids. Comput. Mater. Sci. 88, 92–102 (2014). https://doi.org/10.1016/j.commatsci.2014.02.047

Q. Doan, T.H. Fang, T.H. Chen, T.X. Bui, Effects of void and inclusion sizes on mechanical response and failure mechanism of AlCrCuFeNi2 high-entropy alloy. Eng. Fract. Mech. 252, 107848 (2021). https://doi.org/10.1016/j.engfracmech.2021.107848

F. Maresca, W.A. Curtin, Theory of screw dislocation strengthening in random bcc alloys from dilute to “high-entropy” alloys. Acta Mater. 182, 144–162 (2020). https://doi.org/10.1016/j.actamat.2019.10.007

S. Rao, C. Woodward, B. Akdim, O. Senkov, D. Miracle, Theory of solid solution strengthening of bcc chemically complex alloys. Acta Mater. 209, 116758 (2021). https://doi.org/10.1016/j.actamat.2021.116758

W.A. Maresca, Curtin, Mechanistic origin of high strength in refractory bcc high entropy alloys up to 1900k. Acta Mater. 182, 235–249 (2020). https://doi.org/10.1016/j.actamat.2019.10.015

T. Shi, Z. Su, J. Li, C. Liu, J. Yang, X. He, D. Yun, Q. Peng, C. Lu, Distinct point defect behaviours in body-centered cubic medium-entropy alloy nbzrti induced by severe lattice distortion. Acta Mater. 229, 117806 (2022). https://doi.org/10.1016/j.actamat.2022.117806

C. Wehrenberg, D. McGonegle, C. Bolme, A. Higginbotham, A. Lazicki, F. Tavella, L. Zepeda-Ruiz, J. Wark, Femtosecond measurement of shock wave driven twinning and lattice dynamics. Nature (2017). https://doi.org/10.1038/nature24061

G. Wei, H. Xie, F. Yin, G. Lu, Twinning mechanism asymmetry in body-centered cubic tantalum under [001] uniaxial compression/tension. Phys. Rev. Mater. 5, 123604 (2021). https://doi.org/10.1103/PhysRevMaterials.5.123604

X. Liu, D. Hua, W. Wang, Q. Zhou, S. Li, J. Shi, H. Wang, Atomistic understanding of incipient plasticity in BCC refractory high entropy alloys. J. Alloys Compds. 920, 166058 (2022). https://doi.org/10.1016/j.jallcom.2022.166058

J. Jiang, P. Chen, J. Qiu, W. Sun, I. Saikov, V. Shcherbakov, M. Alymov, Microstructural evolution and mechanical properties of AlxCoCrFeNi high-entropy alloys under uniaxial tension: a molecular dynamics simulations study. Mater. Today Commun. 28, 102525 (2021). https://doi.org/10.1016/j.mtcomm.2021.102525

X. Dai, Y. Kong, J. Li, B. Liu, Extended finnis–sinclair potential for bcc and fcc metals and alloys. J. Phys. 18, 4527 (2006). https://doi.org/10.1088/0953-8984/18/19/008

W. Stewart III., J. Roberts, N. Alexandropolous, K. Salama, Effect of hydrogen on the temperature dependence of the elastic constants of tantalum single crystals. J. Appl. Phys. 48, 75–81 (1977). https://doi.org/10.1063/1.323327

Acknowledgements

EMB thanks support by PICTO–UUMM-2019-00048 and SIIP-UNCuyo grant 06/M008-T1. CJR thanks support by Agencia I+D+i PICT-2018-00773 and a SiiP-UNCuyo grant. MC and NV thank an EVC-CIN Scholarship for scientific vocations. The simulations were run on the Toko-FCEN-UNCuyo computer cluster, part of SNCAD-MinCyT, Argentina. This work used computational resources from CCAD—Universidad Nacional de Córdoba (https://ccad.unc.edu.ar/), which are part of SNCAD—MinCyT, República Argentina.

Author information

Authors and Affiliations

Contributions

FA, NV, and MC: Matias: Formal analysis, Investigation, Writing—Original Draft, Visualization, and Data Curation. OD: Formal analysis, Investigation, Writing—Review & Editing, Visualization, and Data Curation. CJR: Methodology, Validation, Formal analysis, Investigation, Writing—Review & Editing, and Supervision, EMB: Conceptualization, Methodology, Validation, Formal analysis, Investigation, Supervision, Writing—Review & Editing, and Project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aquistapace, F., Vazquez, N., Chiarpotti, M. et al. Atomistic Simulations of Ductile Failure in a b.c.c. High-Entropy Alloy. High Entropy Alloys & Materials 1, 84–95 (2023). https://doi.org/10.1007/s44210-022-00004-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s44210-022-00004-6