Abstract

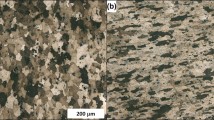

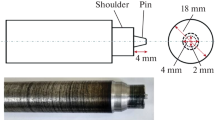

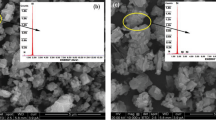

The extraordinary mechanical properties of AA7075-T6 alloy are comparable to that of steel, but its low hardness, high wear rate at room and high temperature have limited its widespread use, so the main aim of this study is to eliminate these weaknesses by producing a hybrid surface composite with the help of an intermetallic compound (Al3Zr) and other reinforcements (Al2O3 and ZrO2). Friction stir processing was chosen for this purpose, so in addition to obtaining extremely refined grains, the formation of common defects, occurring in the conventional methods, could be avoided. Having produced the composite, surface appearance was evaluated and microstructural characteristics were investigated by stereo, light, and FESEM microscopes. Besides not observing any external and internal critical defect, ultra-fine grains were seen. For a detailed investigation, EDS and XRD analyses were used. To assess mechanical properties, tensile and microhardness tests were conducted. Although yield and UTS experienced a fall, the particles set the stage for remarkable improvements in microhardness, cold, and hot wear. Microhardness was raised uniformly in the whole stir zone, and a ~ 48% rise in this property was obtained. Moreover, hot and cold wear resistances were improved up to about 85% and 65%, respectively. Finally, to study the mechanisms of the fracture and wear, the surfaces were scrutinized under SEM and EDS. It was observed that the fracture had a combination of ductile and brittle behaviors and in worn surfaces, instead of cavities formation, micro-cracks and scratches were produced, which are the signs of enhancement in wear resistance.

Similar content being viewed by others

Data availability

The raw data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

Sagar P, Handa A, Kumar G. Metallurgical, mechanical and tribological behavior of Reinforced magnesium-based composite developed Via Friction stir processing. Proc: Inst. Mech. Eng. Part E J. Process Mech. Eng; 2021. https://doi.org/10.1177/09544089211063099.

Patil NA, Pedapati SR, Mamat O, Lubis AMHS. Morphological characterization, statistical modeling and wear behavior of AA7075-titanium carbide-graphite surface composites via friction stir processing. J Mater Res Technol. 2021;11:2160–80. https://doi.org/10.1016/j.jmrt.2021.02.054.

Mondal M, Das H, Hong ST, Jeong BS, Han HN. Local enhancement of the material properties of aluminium sheets by a combination of additive manufacturing and friction stir processing. CIRP Ann. 2019;68(1):289–92. https://doi.org/10.1016/j.cirp.2019.04.109.

Kiani S, Mirsalehi SE. Friction stir additive manufacturing of B4C and graphene reinforced aluminum matrix hybrid nanocomposites using consumable pins. J Mater Res Technol. 2024;28:1094–110.

Jiang HJ, Zhang B, Liu CY, Yang ZX, Ma ZY. Mechanical and damping behavior of age-hardened and non-age-hardened Al alloys after friction stir processing. Acta Metall Sin (English Lett). 2019;32(9):1135–41. https://doi.org/10.1007/s40195-019-00905-3.

Gangil N, Maheshwari S, Siddiquee AN, Abidi MH, El-Meligy MA, Mohammed JA. Investigation on friction stir welding of hybrid composites fabricated on Al–Zn–Mg–Cu alloy through friction stir processing. J Mater Res Technol. 2019;8(5):3733–40. https://doi.org/10.1016/j.jmrt.2019.06.033.

Ostovan F, Azimifar I, Toozandehjani M, Shafiei E, Shamshirsaz M. Synthesis of ex-situ Al5083 reinforced with mechanically-alloyed CNTs and Fe2O3 nanoparticles using friction stir processing. J Mater Res Technol. 2021;14:1670–81. https://doi.org/10.1016/j.jmrt.2021.07.072.

Moustafa EB, Melaibari A, Basha M. Wear and microhardness behaviors of AA7075/SiC-BN hybrid nanocomposite surfaces fabricated by friction stir processing. Ceram Int. 2020;46(10):16938–43. https://doi.org/10.1016/j.ceramint.2020.03.274.

Rizi EC, Ranjbarnodeh E, Mirsalehi SE. Predicting the quantity and type of intermetallic phases in aluminum–steel dissimilar joints produced by zinc interlayer. Weld World. 2023;67(1):151–65.

Soni SK, Manimaran D, Thomas SB, Thomas B. Microstructure and mechanical characterization of Al6061 based composite and nanocomposites prepared via conventional and ultrasonic-assisted melt-stirring techniques. Mater Today Commun. 2023;34:105222.

Serindağ HT, Çam G. Characterizations of microstructure and properties of dissimilar AISI 316L/9Ni Low-alloy cryogenic steel joints fabricated by gas tungsten arc welding. J Mater Eng Perform. 2023;32:7039–49. https://doi.org/10.1007/s11665-022-07601-x.

Zhao W, Zhu Y, Liu Z, Fu A, He H. Mechanism of ultrasonic effects on thermal-stress field in Cu/Al-FSW process. Int J Mech Sci. 2024;27:109101.

Rahmatian B, Dehghani K, Mirsalehi SE. Effect of adding SiC nanoparticles to nugget zone of thick AA5083 aluminium alloy joined by using double-sided friction stir welding. J Manuf Process. 2020;52:152–64. https://doi.org/10.1016/j.jmapro.2020.01.046.

Men J, et al. Investigation on microstructure, mechanical and tribological properties of friction stir processing of AZ31/AlFeCrMoNb surface composite. Mater Chem Phys. 2024. https://doi.org/10.1016/j.matchemphys.2024.129149.

Çam G, Javaheri V, Heidarzadeh A. Advances in FSW and FSSW of dissimilar Al-alloy plates. J Adhes Sci Technol. 2023;37(2):162–94.

Wang Y, et al. Friction surfacing of AA6061 on AA5083 aluminum alloy with adding 316 stainless steel powders: effect of volume fraction of reinforcements. J Mater Res Technol. 2024;30:1800–5.

Moharrami A, Razaghian A, Paidar M, Šlapáková M, Ojo OO, Taghiabadi R (2020) Enhancing the mechanical and tribological properties of Mg2Si-rich aluminum alloys by multi-pass friction stir processing, vol 250. Elsevier B.V.; 2020.

Khaliq UA, et al. A review on friction stir butt welding of aluminum with magnesium: a new insight on joining mechanisms by interfacial enhancement. J Mater Res Technol. 2023;27:4595–624. https://doi.org/10.1016/j.jmrt.2023.10.158.

Moustafa EB, Abushanab WS, Ghandourah EI, Taha MA, Mosleh AO. Advancements in surface reinforcement of AA2024 alloy using hybridized niobium carbide and ceramics particles via FSP technique. Met Mater Int. 2023. https://doi.org/10.1007/s12540-023-01541-4.

Moustafa EB, Taha MA. The effect of mono and hybrid additives of ceramic nanoparticles on the tribological behavior and mechanical characteristics of an Al-based composite matrix produced by friction stir processing. Nanomaterials. 2023;13(14):2148. https://doi.org/10.3390/nano13142148.

Kashaev N, Ventzke V, Çam G. Prospects of laser beam welding and friction stir welding processes for aluminum airframe structural applications. J Manuf Process. 2018;36:571–600.

Küçükömeroğlu T, Aktarer SM, Çam G. Investigation of mechanical and microstructural properties of friction stir welded dual phase (DP) steel. IOP Conf Ser Mater Sci Eng. 2019;629(1):12010.

Abbass MK, Baheer NA. Effect of SiC particles on microstructure and wear behavior of AA6061-T6 aluminum alloy surface composite fabricated by friction stir processing. IOP Conf: Ser. Mater. Sci. Eng; 2020. https://doi.org/10.1088/1757-899X/671/1/012159.

Tonelli L, et al. Effect of FSP parameters and tool geometry on microstructure, hardness, and wear properties of AA7075 with and without reinforcing B4C ceramic particles. Int J Adv Manuf Technol. 2019;102(9–12):3945–61. https://doi.org/10.1007/s00170-019-03442-6.

Liu S, et al. Probe-less friction stir spot processing (PFSSP) of AA5754/AA5083 joint by adding the B4C ceramics: effect of shoulder features on mechanical properties and tribological behavior. Vacuum. 2023;207:111542.

Arun N, Prakash M. The effects of the process parameters on shoulderless friction stir processing on the tribological properties of polylactic acid/basalt composites. Proc Inst Mech Eng Part L J Mater Des Appl; 2023. https://doi.org/10.1177/146442072311957.

Kumar A, Kumar V. Fabrication and optimization of AA7075-7% SiC surface composites using RSM technique via friction stir processing. J Alloy Metall Syst. 2023;3:100022.

Fuse K, Badheka V, Patel V, Andersson J. Dual sided composite formation in Al 6061/B4C using novel bobbin tool friction stir processing. J Mater Res Technol. 2021;13:1709–21. https://doi.org/10.1016/j.jmrt.2021.05.079.

Sharifi Asl N, Mirsalehi SE, Dehghani K. Effect of TiO2 nanoparticles addition on microstructure and mechanical properties of dissimilar friction stir welded AA6063-T4 aluminum alloy and AZ31B-O magnesium alloy. J Manuf Process. 2018;38:338–54.

Azimiroeen G, Kashani-Bozorg SF, Nosko M, Lotfian S. Effect of initial grain size on microstructure and mechanical properties of in situ hybrid aluminium nanocomposites fabricated by friction stir processing. Appl Sci. 2023;13(12):7337. https://doi.org/10.3390/app13127337.

Patel VV, Badheka V, Kumar A. Effect of polygonal pin profiles on friction stir processed superplasticity of AA7075 alloy. J Mater Process Technol. 2017;240:68–76. https://doi.org/10.1016/j.jmatprotec.2016.09.009.

Rajan G, Mula S. Synergetic effects of cryo-FSP on microstructural, mechanical and corrosion behavior of stir cast AA5083-2 wt% SiC nanocomposite. J Manuf Process. 2023;106:19–34. https://doi.org/10.1016/j.jmapro.2023.09.073.

Khodabakhshi F, Gerlich AP, Simchi A, Kokabi AH. Cryogenic friction-stir processing of ultrafine-grained Al-Mg-TiO2 nanocomposites. Mater Sci Eng A. 2015;620:471–82. https://doi.org/10.1016/j.msea.2014.10.048.

Sivanesh Prabhu M, Elaya Perumal A, Arulvel S, Franklin Issac R. Friction and wear measurements of friction stir processed aluminium alloy 6082/CaCO3 composite. Meas J Int Meas Confed. 2019;142:10–20.

Xu N, Zhang M, Li W, Zhao G, Wang X, Liu W. Study on the selectivity of calcium carbonate nanoparticles under the boundary lubrication condition. Wear. 2013;307(1–2):35–43. https://doi.org/10.1016/j.wear.2013.07.010.

Patel V, Badheka V, Li W, Akkireddy S. Hybrid friction stir processing with active cooling approach to enhance superplastic behavior of AA7075 aluminum alloy. Arch Civ Mech Eng. 2019;19(4):1368–80. https://doi.org/10.1016/j.acme.2019.08.007.

Ke L, Huang C, Xing L, Huang K. Al-Ni intermetallic composites produced in situ by friction stir processing. J Alloys Compd. 2010;503(2):494–9. https://doi.org/10.1016/j.jallcom.2010.05.040.

Lee IS, Kao PW, Chang CP, Ho NJ. Formation of Al–Mo intermetallic particle-strengthened aluminum alloys by friction stir processing. Intermetallics. 2013;35:9–14.

Lee IS, Kao PW, Ho NJ. Microstructure and mechanical properties of Al–Fe in situ nanocomposite produced by friction stir processing. Intermetallics. 2008;16(9):1104–8.

Zhang Q, Xiao BL, Wang QZ, Ma ZY. In situ Al 3 Ti and Al 2 O 3 nanoparticles reinforced Al composites produced by friction stir processing in an Al-TiO 2 system. Mater Lett. 2011;65:2070–2. https://doi.org/10.1016/j.matlet.2011.04.030.

A. E384-08a, Standard test method for Micro indentation hardness of materials.

ASTM Standard E8/E8M-13a. Standard Test methods for tension testing of metallic materials. ASTM Int., pp. 1–27, 2013.

ASTM International, ASTM G99-17, Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. Annual Book of ASTM Standards, vol. 05, No. 2016. ASTM International West Conshohocken, pp. 1–6; 2017.

Murray J, Peruzzi A, Abriata JP. The Al-Zr (aluminum-zirconium) system. J Phase Equilibria. 1992;13(3):277–91.

Yaghoubi A, Mirsalehi SE, Jamali A. Investigation on microstructure, mechanical properties and tribological behavior of AlZnMgCu1. 5–T6/zirconia surface nanocomposites developed by FSP. J Mater Res Technol. 2022;20:397–414. https://doi.org/10.1016/j.jmrt.2022.07.093.

Chen CF, Kao PW, Chang LW, Ho NJ. Effect of processing parameters on microstructure and mechanical properties of an Al-Al11Ce3-Al2O3 in-situ composite produced by friction stir processing. Metall Mater Trans A Phys Metall Mater Sci. 2010;41(2):513–22. https://doi.org/10.1007/s11661-009-0115-8.

Khodabakhshi F, Simchi A, Kokabi AH, Gerlich AP, Nosko M. Effects of post-annealing on the microstructure and mechanical properties of friction stir processed Al-Mg-TiO2 nanocomposites. Mater Des. 2014;63:30–41. https://doi.org/10.1016/j.matdes.2014.05.065.

Pratap C, Chandra P, Butola R, Shukla A. Fabrication and characterization of AA6063/B 4 C metal matrix surface nanocomposite using friction stir processing. ECS J Solid State Sci Technol. 2022;11(3):033010. https://doi.org/10.1149/2162-8777/ac5c81.

Khodabakhshi F, Gerlich AP, Švec P. Fabrication of a high strength ultra-fine grained Al-Mg-SiC nanocomposite by multi-step friction-stir processing. Mater Sci Eng A. 2017;698:313–25. https://doi.org/10.1016/j.msea.2017.05.065.

Heidarzadeh A, et al. Friction stir welding/processing of metals and alloys: a comprehensive review on microstructural evolution. Prog Mater Sci. 2021;117:100752.

Bagheri B, Abbasi M, Abdollahzadeh A, Mirsalehi SE. Effect of second-phase particle size and presence of vibration on AZ91/SiC surface composite layer produced by FSP. Trans Nonferrous Met Soc China. 2020;30(4):905–16. https://doi.org/10.1016/S1003-6326(20)65264-5.

Porter DA, Easterling KE, Easterling KE, Phase Transformations in Metals and Alloys (Revised Reprint). CRC press; 2009.

G. S. Rohrer (2010) Introduction to grains, phases, and interfaces—an interpretation of microstructure. Trans AIME, 1948, vol. 175, pp. 15–51, by C.S. Smith,” Metall. Mater. Trans. B Process Metall. Mater. Process. Sci., vol. 41, no. 3, p. 457. Doi: https://doi.org/10.1007/s11663-010-9364-6.

Jamali A, Mirsalehi SE. Investigation on effects of traverse speed and number of passes on mechanical and abrasive properties of AA7075-T6/ZrO2 surface nanocomposite produced using friction stir processing. Weld World. 2022. https://doi.org/10.1007/s40194-022-01331-3.

Khodabakhshi F, Simchi A, Kokabi AH, Nosko M, Simanĉik F, Švec P. Microstructure and texture development during friction stir processing of Al-Mg alloy sheets with TiO2 nanoparticles. Mater Sci Eng A. 2014;605:108–18. https://doi.org/10.1016/j.msea.2014.03.008.

Jamali A, Mirsalehi SE. Production of AA7075/ZrO2 nanocomposite using friction stir processing: Metallurgical structure, mechanical properties and wear behavior. CIRP J Manuf Sci Technol. 2022;37:55–69. https://doi.org/10.1016/j.cirpj.2021.12.008.

Rinu G, Singh S, Nirsanametla Y, Dipati AK, Prakash C, Kotecha K. Experimental investigation of defect formation, microstructure and mechanical properties in friction stir welding of AA5086. Metall Res Technol. 2022;119(5):514.

Ocak-Araz S, Birden A, Bayca SU, Bican O. Effect of powder-pack boronizing on the microhardness, wear, and corrosion behaviors of AISI 304L steel. J Mater Eng Perform. 2024;33(1):166–72.

Bölükbaşı ÖS, Serindağ T, Gürol U, Günen A, Çam G. Improving oxidation resistance of wire arc additive manufactured Inconel 625 Ni-based superalloy by pack aluminizing. CIRP J Manuf Sci Technol. 2023;46:89–97.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jamali, A., Mirsalehi, S.E., Yaghoubi, A. et al. Effect of ex situ Al3Zr intermetallic on cold and hot wear behaviors and mechanical properties of FSPed surface hybrid nanocomposite of high-strength aluminum matrix. Arch. Civ. Mech. Eng. 24, 147 (2024). https://doi.org/10.1007/s43452-024-00971-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-024-00971-0