Abstract

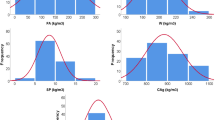

Self-compacted concrete (SCC) is one of the special types of concrete. The SCC represents one of the most significant developments in concrete technology over the previous two decades. It can compact itself using its weight without requiring vibration due to its excellent fresh characteristics, which allow it to flow into a uniform level under the impact of gravity. Since cement manufacturing is one of the largest contributors to CO2 gas emissions into the atmosphere, fly ash (FA) is used in concrete as a cement replacement. Currently, FA-modified SCC is widely utilized in construction. This research aimed to study the potential of soft computing models in predicting the compressive strength (CS) and slump flow diameter (SL) of self-compacted concrete modified with different fly ash content. Hence, two databases were created, and relevant experimental data was collected from previous studies. The first database consists of 303 data points and is used to predict the CS. The second database predicts the SL and contains 86 data points. The dependent parameters are the CS, which varies from 9.7 to 79.2 MPa, and the SL, which varies from 615 to 800 mm. The identical five independent parameters are available in each database. The ranges for CS prediction are water-to-binder ratio (0.27–0.9), cement (134.7–540 kg/m3), sand (478–1180 kg/m3), fly ash (0–525 kg/m3), coarse aggregate (578–1125 kg/m3), and superplasticizer (0–1.4%). The data ranges for the SL prediction, on the other hand, are as follows: water-to-binder ratio (0.26–0.58), cement (83–733 kg/m3), sand (624–1038 kg/m3), fly ash (0–468 kg/m3), coarse aggregate (590–966 kg/m3), and superplasticizer (0.1–21.84%). Each database has developed three models for the prediction: full-quadratic (FQ), interaction (IN), and M5P-tree models. Each database is divided into two groups, with training comprising two-thirds of the total data points and testing containing one-third. As a result, 202 training data and 101 testing data are in the first database. The other database consists of 57 data points for training and 29 for testing. Various statistical tools are used to evaluate the performance of each proposed model, such as R2 (correlation of coefficient), RMSE (root mean squared error), SI (scatter index), MAE (mean absolute error), StDev, OBJ (objective value), a-20 index, and Z-score. The results showed that the FQ and IN models have the highest accuracy and reliability in predicting the compressive strength and slump flow of FA-based SCC, respectively. Moreover, the sensitivity analysis revealed that the cement content is the most influential contributor to the mixtures.

Similar content being viewed by others

Data availability

The data supporting the conclusions of this article are included with the article.

References

Okamura H. Self-compacting high-performance concrete. Concr Int Design Constr. 1997;19(7):50–4.

Ozawa K. Development of high performance concrete based on the durability design of concrete structures. EASEC-2. 1989;1:445–50.

Khambra G, Shukla P. Novel machine learning applications on fly ash based concrete: an overview. Mater Today Proc. 2023;80:3411–7.

Shi C et al. Design and application of self-compacting lightweight concrete. In: SCC’2005-China: 1st international symposium on design, performance and use of self-consolidating concrete. London: RILEM Publications SARL; 2005.

Shi C, Wu Y. Mixture proportioning and properties of self-consolidating lightweight concrete containing glass powder. ACI Mater J. 2005;102(5):1.

Goodier CI, Development of self-compacting concrete; 2003.

Liu YH, Xie YJ, Long GC. Development of self-compacting concrete. J Chin Ceram Soc. 2007;35(5):671–8.

Han J, Fang H, Wang K. Design and control shrinkage behavior of high-strength self-consolidating concrete using shrinkage-reducing admixture and superabsorbent polymer. J Sustain Cem Based Mater. 2014;2014:1–9.

Esmaeilkhanian B, Khayat KH, Yahia A, Feys D. Effects of mix design parameters and rheological properties on dynamic stability of selfconsolidating concrete. Cem Concr Compos. 2014;54:21–8.

Siddique R, Aggarwal P, Aggarwal Y. Mechanical and durability properties of self-compacting concrete containing fly ash and bottom ash. J Sustain Cem Based Mater. 2012;1(3):67–82.

Wang XH, Wang KJ, Taylor P, Morcous G. Assessing particle packing based selfconsolidating concrete mix design method. Constr Build Mater. 2014;70:439–52.

Basu P, Thomas BS, Gupta RC, Agrawal V. Properties of sustainable self-compacting concrete incorporating discarded sandstone slurry. J Clean Prod. 2021;281:125313.

Bouzuubaa N, Lachemi M. Self compacting concrete incorporating high volumes of class F fly ash preliminary results. Cem Concr Res. 2001;2001:413–20.

Deilami S, Aslani F, Elchalakani M. An experimental study on the durability and strength of SCC incorporating FA, GGBS and MS. Proc Inst Civ Eng Struct Build. 2018;2018:1–3.

Ismael Jaf DK. Soft computing and machine learning-based models to predict the slump and compressive strength of self-compacted concrete modified with fly ash. Sustainability. 2023;15(15):11554.

Neville AM, Brooks JJ. Concrete technology. England: Longman Scientific & Technical; 1987. p. 242–6.

Neville AM. Properties of concrete, vol. 4. London: Longman; 1995.

Douglas RP, Bui VK, Akkaya Y, Shah SP. Properties of self-consolidating concrete containing class F fly ash: with a verification of the minimum paste volume method. Spec Publ. 2006;233:45–64.

Pathak N, Siddique R. Properties of self-compacting-concrete containing fly ash subjected to elevated temperatures. Constr Build Mater. 2012;30:274–80.

Ghezal A, Khayat KH. Optimizing self-consolidating concrete with limestone filler by using statistical factorial design methods. Mater J. 2002;99:264–72.

Dinakar P, Babu KG, Santhanam M. Mechanical properties of high-volume fly ash self-compacting concrete mixtures. Struct Concr. 2008;9:109–16.

Bui VK, Akkaya Y, Shah SP. Rheological model for self-consolidating concrete. Mater J. 2002;99:549–59.

Sonebi M. Applications of statistical models in proportioning medium-strength self-consolidating concrete. Mater J. 2004;101:339–46.

Sonebi M. Medium strength self-compacting concrete containing fly ash: modelling using factorial experimental plans. Cem Concr Res. 2004;34:1199–208.

Dinakar P. Design of self-compacting concrete with fly ash. Mag Concr Res. 2012;64:401–9.

Bouzoubaâ N, Lachemi M. Self-compacting concrete incorporating high volumes of class F fly ash: preliminary results. Cem Concr Res. 2001;31:413–20.

Patel R, Hossain KMA, Shehata M, Bouzoubaa N, Lachemi M. Development of statistical models for mixture design of high-volume fly ash self-consolidating concrete. Mater J. 2004;101:294–302.

Farooq F, Czarnecki S, Niewiadomski P, Aslam F, Alabduljabbar H, Ostrowski KA, Malazdrewicz S. A comparative study for the prediction of the compressive strength of self-compacting concrete modified with fly ash. Materials. 2021;14(17):4934.

Hemalatha T, Ramaswamy A, Chandra Kishen JM. Micromechanical analysis of self compacting concrete. Mater Struct. 2015;48:3719–34.

Sun ZJ, Duan WW, Tian ML, Fang YF. Experimental research on self-compacting concrete with different mixture ratio of fly ash. In: Advanced materials research, vol 236. Bäch, Switzerland: Trans Tech Publications Ltd; 2011. p. 490–5.

Sukumar B, Nagamani K, Raghavan RS. Evaluation of strength at early ages of self-compacting concrete with high volume fly ash. Constr Build Mater. 2008;22:1394–401.

Jalal M, Mansouri E. Effects of fly ash and cement content on rheological, mechanical, and transport properties of highperformance self-compacting concrete. Sci Eng Compos Mater. 2012;19:393–405.

Boel V, Audenaert K, De Schutter G, Heirman G, Vandewalle L, Desmet B, Vantomme J. Transport properties of self compacting concrete with limestone filler or fly ash. Mater Struct. 2007;40:507–16.

Ramanathan P, Baskar I, Muthupriya P, Venkatasubramani R. Performance of self-compacting concrete containing different mineral admixtures. KSCE J Civil Eng. 2013;17:465–72.

Venkatakrishnaiah R, Sakthivel G. Bulk utilization of flyash in self compacting concrete. KSCE J Civil Eng. 2015;19:2116–20.

Barbhuiya S. Effects of fly ash and dolomite powder on the properties of self-compacting concrete. Constr Build Mater. 2011;25:3301–5.

Bingöl AF, Tohumcu İ. Effects of different curing regimes on the compressive strength properties of self compacting concrete incorporating fly ash and silica fume. Mater Des. 2013;51:12–8.

Güneyisi E, Gesoğlu M, Özbay E. Strength and drying shrinkage properties of self-compacting concretes incorporating multi-system blended mineral admixtures. Constr Build Mater. 2010;24:1878–87.

Nehdi M, Pardhan M, Koshowski S. Durability of self-consolidating concrete incorporating high-volume replacement composite cements. Cem Concr Res. 2004;34:2103–12.

Krishnapal P, Yadav RK, Rajeev C. Strength characteristics of self compacting concrete containing fly ash. Res J Eng Sci ISSN. 2013;2278:9472.

Dhiyaneshwaran S, Ramanathan P, Baskar I, Venkatasubramani R. Study on durability characteristics of self-compacting concrete with fly ash. Jordan J Civ Eng. 2013;7:342–53.

Siddique R. Properties of self-compacting concrete containing class F fly ash. Mater Des. 2011;32:1501–7.

Mahalingam B, Nagamani K. Effect of processed fly ash on fresh and hardened properties of self compacting concrete. Int J Earth Sci Eng. 2011;4:930–40.

Muthupriya P, Sri PN, Ramanathan MP, Venkatasubramani R. Strength and workability character of self compacting concrete with GGBFS, FA and SF. Int J Emerg Trends Eng Dev. 2012;2:424–34 (Sustainability 2023, 15, 11554 39 of 40).

Siddique R, Aggarwal P, Aggarwal Y. Influence of water/powder ratio on strength properties of self-compacting concrete containing coal fly ash and bottom ash. Constr Build Mater. 2012;29:73–81.

Gesoğlu M, Güneyisi E, Özbay E. Properties of self-compacting concretes made with binary, ternary, and quaternary cementitious blends of fly ash, blast furnace slag, and silica fume. Constr Build Mater. 2009;23:1847–54.

Nepomuceno MC, Pereira-de-Oliveira LA, Lopes SMR. Methodology for the mix design of self-compacting concrete using different mineral additions in binary blends of powders. Constr Build Mater. 2014;64:82–94.

Gettu R, Izquierdo J, Gomes PCC, Josa A. Development of high-strength self-compacting concrete with fly ash: a four-step experimental methodology. In: Tam CT, Ho DW, Paramasivam P, Tan TH, editors. Proceedings of the 27th conference on our world in concrete & structures, Singapore, 29–30 August 2002. Singapore: Premier Pte. Ltd.; 2002. p. 217–24.

Sahmaran M, Yaman İÖ, Tokyay M. Transport and mechanical properties of self consolidating concrete with high volume fly ash. Cem Concr Compos. 2009;31:99–106.

Liu M. Self-compacting concrete with different levels of pulverized fuel ash. Constr Build Mater. 2010;24:1245–52.

Jawahar JG, Sashidhar C, Reddy IR, Peter JA. Micro and macrolevel properties of fly ash blended self compacting concrete. Mater Des. 2013;1980–2015(46):696–705.

Jaf DKI, Abdulrahman PI, Mohammed AS, Kurda R, Qaidi SM, Asteris PG. Machine learning techniques and multi-scale models to evaluate the impact of silicon dioxide (SiO2) and calcium oxide (CaO) in fly ash on the compressive strength of green concrete. Constr Build Mater. 2023;400:132604.

Abdalla A, Salih A. Microstructure and chemical characterizations with soft computing models to evaluate the influence of calcium oxide and silicon dioxide in the fly ash and cement kiln dust on the compressive strength of cement mortar. Resour Conser Recycling Adv. 2022;15:200090.

Ali R, Muayad M, Mohammed AS, Asteris PG. Analysis and prediction of the effect of Nanosilica on the compressive strength of concrete with different mix proportions and specimen sizes using various numerical approaches. Struct Concr. 2023;24(3):4161–84.

Emad W, Mohammed AS, Bras A, Asteris PG, Kurda R, Muhammed Z, Sihag P. Metamodel techniques to estimate the compressive strength of UHPFRC using various mix proportions and a high range of curing temperatures. Constr Build Mater. 2022;349:128737.

Jaf DKI, Abdulrahman AS, Abdulrahman PI, Mohammed AS, Kurda R, Ahmed HU, Faraj RH. Effitioned soft computing models to evaluate the impact of silicon dioxide (SiO2) to calcium oxide (CaO) ratio in fly ash on the compressive strength of concrete. J Build Eng. 2023;74:106820.

Piro NS, Salih A, Hamad SM, Kurda R. Comprehensive multiscale techniques to estimate the compressive strength of concrete incorporated with carbon nanotubes at various curing times and mix proportions. J Market Res. 2021;15:6506–27.

Quinlan JR. Learning with continuous classes. In: 5th Australian joint conference on artificial intelligence, vol. 92; 1992. p. 343–8.

Ahmad SA, Rafiq SK, Hilmi HDM, Ahmed HU. Mathematical modeling techniques to predict the compressive strength of pervious concrete modified with waste glass powders. Asian J Civ Eng. 2023;2023:1–13.

Barkhordari MS, Armaghani DJ, Mohammed AS, Ulrikh DV. Data-driven compressive strength prediction of fly ash concrete using ensemble learner algorithms. Buildings 2022;12(2):132.

Abdalla AA, Salih Mohammed A. Theoretical models to evaluate the effect of SiO2 and CaO contents on the long-term compressive strength of cement mortar modified with cement kiln dust (CKD). Arch Civ Mech Eng. 2022;22(3):105.

Mohammed A, Rafiq S, Mahmood W, Noaman R, Hind AD, Ghafor K, Qadir W. Microstructure characterizations, thermal properties, yield stress, plastic viscosity and compression strength of cement paste modified with nanosilica. J Mater Res Technol. 2020;9(5):10941–56.

Burhan L, Ghafor K, Mohammed A. Modeling the effect of silica fume on the compressive, tensile strengths and durability of NSC and HSC in various strength ranges. J Build Pathol Rehabil. 2019;4:1–19.

Abdalla AA, Mohammed AS, Rafiq S, Noaman R, Qadir WS, Ghafor K, Fairs R. Microstructure, chemical compositions, and soft computing models to evaluate the influence of silicon dioxide and calcium oxide on the compressive strength of cement mortar modified with cement kiln dust. Constr Build Mater. 2022;341:127668.

Timur Cihan M. Prediction of concrete compressive strength and slump by machine learning methods. Adv Civ Eng. 2019;2019:1–11.

Ahmed HU, Mohammed AA, Mohammed A (2022) Soft computing models to predict the compressive strength of GGBS/FA-geopolymer concrete. PloS one 17(5):e0265846.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflcit of interest

The authors declare that they have no conflcit of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Omer, B., Jaf, D.K.I., Malla, S.K. et al. Exploring the potential of soft computing for predicting compressive strength and slump flow diameter in fly ash-modified self-compacting concrete. Archiv.Civ.Mech.Eng 24, 95 (2024). https://doi.org/10.1007/s43452-024-00910-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-024-00910-z