Abstract

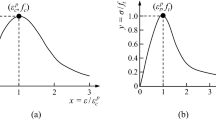

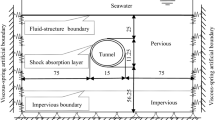

Yielding support is effective in controlling excessive deformation of soft rock in squeezing tunnel engineering, and the developed polyethylene (PE) pipe filled with foamed concrete is a good choice serving as a yielding support. To deal with distortions brought on by significant mesh deformations and to enhance visualization, a numerical simulation method based on finite element method-smoothed particle hydrodynamics coupling (FEM-SPH) is adopted taking into account the progressive failure of PE pipes filled with foamed concrete (FC-PE) during deformation. By simulating the gradual failure of foamed concrete through smooth particle flow and the wrapped PE pipe using the finite element method, the damage process of the filled pipe has been examined. Comparison with experimental results demonstrates the superiority of the proposed model in terms of computational efficiency and accuracy, investigating the impact of several critical variables on the energy absorption capabilities of FC-PE, as well as setting pertinent evaluation indicators based on practical engineering application conditions. Additionally, numerical results demonstrate that the frictional characteristics between PE pipe and foamed concrete have little effects on the deformation energy absorption properties. The numerical results also demonstrate that the FC-PE’s diameter has a positive impact on both the energy absorption efficiency and the usage efficiency, while thicker FC-PE having a lower energy absorption efficiency.

Similar content being viewed by others

Data availability

The data are available from the corresponding author on reasonable request.

References

Aktay L, Johnson AF, Toksoy AK, Kröplin BH, Güden M. Modeling the progressive axial crushing of foam-filled aluminum tubes using smooth particle hydrodynamics and coupled finite element model/smooth particle hydrodynamics. Mater Des. 2008;29(3):569–75. https://doi.org/10.1016/j.matdes.2007.03.010.

Amran YHM, Farzadnia N, Abang Ali AA. Properties and applications of foamed concrete: a review. Constr Build Mater. 2015;101:990–1005. https://doi.org/10.1016/j.conbuildmat.2015.10.112.

Barla G. Full-face excavation of large tunnels in difficult conditions. J Rock Mech Geotech Eng. 2016;8(3):294–303. https://doi.org/10.1016/j.jrmge.2015.12.003.

Barla G, Bonini M, Semeraro M. Analysis of the behaviour of a yield-control support system in squeezing rock. Tunn Undergr Space Technol. 2011;26(1):146–54. https://doi.org/10.1016/j.tust.2010.08.001.

Baroutaji A, Sajjia M, Olabi A-G. On the crashworthiness performance of thin-walled energy absorbers: recent advances and future developments. Thin-Walled Struct. 2017;118:137–63. https://doi.org/10.1016/j.tws.2017.05.018.

Bonini M, Barla G. The Saint Martin La Porte access adit (Lyon–Turin Base Tunnel) revisited. Tunn Undergr Space Technol. 2012;30:38–54. https://doi.org/10.1016/j.tust.2012.02.004.

Cantieni L, Anagnostou G. The interaction between yielding supports and squeezing ground. Tunn Undergr Space Technol. 2009;24(3):309–22. https://doi.org/10.1016/j.tust.2008.10.001.

Chen W, Tian H, Yang F, Geng Y. Study of effects of foam concrete preset deformation layer on long-term stability of deep soft rock tunnel. Rock Soil Mech. 2011;32:2577–83.

Du M, Wang X, Zhang Y, Li L, Zhang P. In-situ monitoring and analysis of tunnel floor heave process. Eng Fail Anal. 2020;109:104323. https://doi.org/10.1016/j.engfailanal.2019.104323.

Gao C, Zhou Z, Li Z, Li L, Cheng S. Peridynamics simulation of surrounding rock damage characteristics during tunnel excavation. Tunn Undergr Space Technol. 2020;97:103289. https://doi.org/10.1016/j.tust.2020.103289.

Gedikli H. Crashworthiness optimization of foam-filled tailor-welded tube using coupled finite element and smooth particle hydrodynamics method. Thin-Walled Struct. 2013;67:34–48. https://doi.org/10.1016/j.tws.2013.01.020.

Goel RK. Tunnelling through weak and fragile rocks of Himalayas. Int J Min Sci Technol. 2014;24(6):783–90. https://doi.org/10.1016/j.ijmst.2014.10.008.

He M, Guo Z. Mechanical property and engineering application of anchor bolt with constant resistance and large deformation. Chin J Rock Mech Eng. 2014;33:1297–308.

He H, Karsai A, Liu B, Hammond FL, Goldman DI, Arson C. Simulation of compound anchor intrusion in dry sand by a hybrid FEM+SPH method. Comput Geotech. 2023;154:105137. https://doi.org/10.1016/j.compgeo.2022.105137.

Jiang H, Zhao H, Gao K, Wang O, Wang Y, Meng D. Numerical investigation of hard rock breakage by high-pressure water jet assisted indenter impact using the coupled SPH/FEM method. Powder Technol. 2020;376:176–86. https://doi.org/10.1016/j.powtec.2020.08.028.

Kimura F, Okabayashi N, Kawamoto T. Tunnelling through squeezing rock in two large fault zones of the Enasan Tunnel II. Rock Mech Rock Eng. 1987;20(3):151–66. https://doi.org/10.1007/BF01020366.

Kimura F, Okabayashi N, Kawamoto T. Tunnelling through squeezing rock in two large fault zones of the Enasan Tunnel II. Int J Rock Mech Min Sci Geomech Abstr. 1988;25(2):86. https://doi.org/10.1016/0148-9062(88)92141-9.

Lagarón JM, López-Quintana S, Rodriguez-Cabello JC, Merino JC, Pastor JM. Comparative study of the crystalline morphology present in isotropic and uniaxially stretched “conventional” and metallocene polyethylenes. Polymer. 2000;41(8):2999–3010. https://doi.org/10.1016/S0032-3861(99)00459-0.

Lee BJ, Argon AS, Parks DM, Ahzi S, Bartczak Z. Simulation of large strain plastic deformation and texture evolution in high density polyethylene. Polymer. 1993;34(17):3555–75. https://doi.org/10.1016/0032-3861(93)90039-D.

Luo G, Zhao Y, Shen W, Wu M. Dynamics of bouldery debris flow impacting onto rigid barrier by a coupled SPH-DEM-FEM method. Comput Geotech. 2022;150:104936. https://doi.org/10.1016/j.compgeo.2022.104936.

Mardalizad A, Scazzosi R, Manes A, Giglio M. Testing and numerical simulation of a medium strength rock material under unconfined compression loading. J Rock Mech Geotech Eng. 2018;10(2):197–211. https://doi.org/10.1016/j.jrmge.2017.11.009.

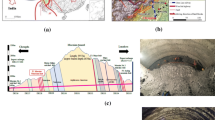

Meng L, Li T, Jiang Y, Wang R, Li Y. Characteristics and mechanisms of large deformation in the Zhegu mountain tunnel on the Sichuan-Tibet highway. Tunn Undergr Space Technol. 2013;37:157–64. https://doi.org/10.1016/j.tust.2013.03.009.

Meng F, Song J, Yue Z, Zhou H, Wang X, Wang Z. Failure mechanisms and damage evolution of hard rock joints under high stress: Insights from PFC2D modeling. Eng Anal Bound Elem. 2022;135:394–411. https://doi.org/10.1016/j.enganabound.2021.12.007.

Moritz B. Yielding elements-requirements, overview and comparison. Geomech Tunn. 2011;4(3):221–36. https://doi.org/10.1002/geot.201100014.

Popov AA, Russak AV, Gladilin MP, Zaikov GY. Blends of polypropylene and high density polyethylene. Polym Sci USSR. 1986;28(5):1208–15. https://doi.org/10.1016/0032-3950(86)90273-X.

Rodríguez R, Díaz-Aguado MB. Deduction and use of an analytical expression for the characteristic curve of a support based on yielding steel ribs. Tunn Undergr Space Technol. 2013;33:159–70. https://doi.org/10.1016/j.tust.2012.07.006.

Tan X, Chen W, Liu H, Chan AHC, Tian H, Meng X, Deng X. A combined supporting system based on foamed concrete and U-shaped steel for underground coal mine roadways undergoing large deformations. Tunn Undergr Space Technol. 2017;68:196–210. https://doi.org/10.1016/j.tust.2017.05.023.

Tian H, Chen W, Tan X, Tian Y, Zhang N. Investigating polymeric foam materials as compressible layer for tunnelling in squeezing ground conditions. Tunn Undergr Sp Technol. 2022;122:104391. https://doi.org/10.1016/j.tust.2022.104391.

Wang FN, Guo ZB, Qiao XB, Fan JY, Li W, Mi M, et al. Large deformation mechanism of thin-layered carbonaceous slate and energy coupling support technology of NPR anchor cable in Minxian Tunnel: a case study. Tunn Undergr Space Technol. 2021;117:104151. https://doi.org/10.1016/j.tust.2021.104151.

Wang W, Wu Y, Wu H, Yang C, Feng Q. Numerical analysis of dynamic compaction using FEM-SPH coupling method. Soil Dyn Earthq Eng. 2021;140:106420. https://doi.org/10.1016/j.soildyn.2020.106420.

Wang J, Zhang Y, Qin Z, Song S, Lin P. Analysis method of water inrush for tunnels with damaged water-resisting rock mass based on finite element method-smooth particle hydrodynamics coupling. Comput Geotech. 2020;126:103725. https://doi.org/10.1016/j.compgeo.2020.103725.

Windsor CR, Thompson AG. 16—Rock reinforcement—technology, testing, design and evaluation. In: Hudson JA, editor. Excavation, support and monitoring. Turkey: Pergamon; 1993. p. 451–84.

Wu H, Fan F, Yang X, Wang Z, Lai J, Xie Y. Large deformation characteristics and treatment effect for deep bias tunnel in broken phyllite: a case study. Eng Fail Anal. 2022;135:106045. https://doi.org/10.1016/j.engfailanal.2022.106045.

Xiang Y, Wang M, Yu T, Yang L. Key performance indicators of tubes and foam-filled tubes used as energy absorbers. Int J Appl Mech. 2015;07(04):1550060. https://doi.org/10.1142/S175882511550060X.

Xu G, He C, Yang Q, Wang B. Progressive failure process of secondary linin of a tunnel under creep effect of surrounding rock. Tunn Undergr Space Technol. 2019;90:76–98. https://doi.org/10.1016/j.tust.2019.04.024.

Yang J, Chen W, Yang D, Yuan J. Numerical determination of strength and deformability of fractured rock mass by FEM modeling. Comput Geotech. 2015;64:20–31. https://doi.org/10.1016/j.compgeo.2014.10.011.

Yu W, Wang B, Zi X, Guo X, Wang Z. Effect of prestressed anchorage system on mechanical behavior of squeezed soft rock in large-deformation tunnel. Tunn Undergr Space Technol. 2023;131:104782. https://doi.org/10.1016/j.tust.2022.104782.

Zhang ZD. Discussion and study on large deformation of tunnel in squeezing ground, 5−12+40 modern. Tunn Technol. 2003. https://doi.org/10.13807/j.cnki.mtt.2003.02.002.

Zhang R, Chen G, Zou J, Zhao L, Jiang C. Study on roof collapse of deep circular cavities in jointed rock masses using adaptive finite element limit analysis. Comput Geotech. 2019;111:42–55. https://doi.org/10.1016/j.compgeo.2019.03.003.

Zhang C, Tan X, Tian H, Chen W. Lateral compression and energy absorption of foamed concrete-filled polyethylene circular pipe as yielding layer for high geo-stress soft rock tunnels. Int J Min Sci Technol. 2022;32(5):1087–96. https://doi.org/10.1016/j.ijmst.2022.08.011.

Zhou Z, Zhang D, Gao C, Li Z, Li M, Liu G. A PD-FEM approach for fast solving static failure problems and its engineering application. Eng Fract Mech. 2022;262:108269. https://doi.org/10.1016/j.engfracmech.2022.108269.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51991392 and 42293355).

Author information

Authors and Affiliations

Contributions

XC contributed to methodology, simulation, writing—original draft; XL helped in methodology, simulation, and writing—revising. XT contributed to laboratory tests on foamed concrete. DY helped in laboratory tests on PE material. HT contributed to numerical simulation. WC helped in conceptualization, supervision, and writing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

This study was approved by the Institutional Ethics Committee of Institute of Rock and Soil Mechanics, Chinese Academy of Science. Ethics approval was not required for this research.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ci, X., Liu, X., Tan, X. et al. Numerical simulation on progressive failure of yielding support material for squeezing tunnel. Archiv.Civ.Mech.Eng 24, 9 (2024). https://doi.org/10.1007/s43452-023-00813-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-023-00813-5