Abstract

Background

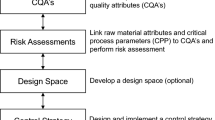

For pharmaceutical products, an in-depth understanding of manufacturing processes and quality risks associated with quality by design (QbD) development enables the production of high-quality products. Product recall due to quality issues could be minimized for QbD-developed products. Furthermore, the review period instituted by regulatory authorities could be shortened by allowing reviewers to access technical documents with QbD elements. The aim of this study was to examine the impact of QbD development from the viewpoints of regulatory flexibility, product quality related to recall, and review period in Pharmaceuticals and Medical Devices Agency (PMDA) in Japan.

Methods

QbD developments for new active ingredients, approved from 2009 to 2018, were surveyed in the PMDA review reports, and review periods were investigated on the PMDA website. Voluntary product recalls and their rationale were investigated using the website of the Japan Ministry of Health, Labour and Welfare.

Results

Although the developmental ratio with QbD elements was increased from 9% in 2009 to 71% in 2018, the development of design space for drug substances and products between 2009 and 2018 was only 2%, and real time release testing (RTRT) for drug products was limited to 3%. Voluntary recall and extension of the review period for QbD-developed products were not observed.

Conclusion

The advantages of systematic QbD development were suggested for no voluntary recall of QbD-developed products. Conversely, applicants did not actively seek regulatory flexibility with design space or RTRT, and QbD development failed to impact the PMDA review period.

Similar content being viewed by others

References

Beg S, Hasnain M, Rahman M, Swain S. Pharmaceutical quality by design. Amsterdam: Elsevier; 2019. p. 1–17.

International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use. ICH harmonised tripartite guideline, pharmaceutical development O8(R2). https://www.ich.org/page/quality-guidelines. Accessed 29 Jan 2020.

ICH Quality Implementation Working Group. Points to Consider (R2). https://www.pmda.go.jp/files/000156389.pdf. Accessed 29 Jan 2020.

Kourti T, Davis B. The business benefits of quality by design (QbD). Pharm Eng. 2012;32:1–10.

Matsuda Y. Status and challenges of pharmaceutical development by QbD. Paper presented at: Japan society of pharmaceutical machinery and engineering 23rd convention; October 10, 2013; Japan. https://www.pmda.go.jp/files/000157890.pdf#search=%27%E8%A3%BD%E5%89%A4%E6%A9%9F%E6%A2%B0%E6%8A%80%E8%A1%93%E5%AD%A6%E4%BC%9A+23%E5%9B%9E%27. Accessed 29 Jan 2020.

Martin-Moe S, Lim F, Wong R, Sreedhara A, Sundaram J, Sane S. A new roadmap for biopharmaceutical drug product development: integrating development, validation, and quality by design. J Pharm Sci. 2011;100:3031–41.

Thapa P, Thapa R, Choi D, Jeong S. Effects of pharmaceutical processes on the quality of ethylcellulose coated pellets: quality by design approach. Powder Technol. 2018;339:25–38.

Ohage E, Iverson R, Krummen L, Taticek R, Vega M. QbD implementation and Post Approval Lifecycle Management (PALM). Biologicals. 2016;44:332–40.

Evans R, Bochmann E, Kyeremateng S, Gryczke A, Wagner K. Holistic QbD approach for hot-melt extrusion process design space evaluation: linking materials science, experimentation and process modeling. Eur J Pharm Biopharm. 2019;141:149–60.

Finkler C, Krummen L. Introduction to the application of QbD principles for the development of monoclonal antibodies. Biologicals. 2016;44:282–90.

Kuno K, Toyoshima S. Review experiences and regulatory challenges for pharmaceutical development in Japan using a quality-by-design approach. Ther Innov Regul Sci. 2016;50(3):368–74.

Pharmaceuticals and Medical Devices Agency. Information search for medical drugs (in Japanese). https://www.pmda.go.jp/PmdaSearch/iyakuSearch/. Accessed 29 Jan 2020.

PMDA website recall information [in Japanese]. https://www.pmda.go.jp/safety/info-services/drugs/calling-attention/recall-info/0002.html. Accessed 29 Jan 2019.

Information on voluntary recall for medical products [in Japanese]. https://www.mhlw.go.jp/stf/seisakunitsuite/bunya/kenkou_iryou/iyakuhin/kaisyu/index.html. Accessed 29 Jan 2020.

Inoue S. Regulatory update from MHLW/PMDA. Paper presented at: 5th joint conference of Taiwan and Japan on medical products regulation; December 1, 2017; Taipei. https://www.pmda.go.jp/files/000221880.pdf#search=%27PMDA+conditinal+early+approval%27. Accessed 29 Jan 2020.

Guidance for Industry. Q8, Q9 and Q10 Questions & Answers (R4). https://www.fda.gov/media/78668/download. Accessed 29 Jan 2020.

Jiang M, Severson K, Love C, et al. Opportunities and challenges of real-time release testing in biopharmaceutical manufacturing. Biotechnol Bioeng. 2017;114:2445–56.

Goodwin D, van den Ban S, Denham M, Barylski I. Real time release testing of tablet content and content uniformity. Int J Pharm. 2018;537:183–92.

Moore C. Regulatory perspective on real time release testing (RTRT). Paper presented at AAPS annual meeting; October 20, 2011; Washington, D.C. https://www.fda.gov/media/84037/download. Accessed 29 Jan 2020.

International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use. ICH harmonised tripartite guideline, specifications: test procedures and acceptance criteria for new drug substances and new drug products: chemical substances Q6A. https://www.ich.org/page/quality-guidelines. Accessed 29 Jan 2020.

Aoyama A. PMDA’s efforts to create innovative technologies [in Japanese]. Paper presented at Japan society of pharmaceutical machinery and engineering 27th convention; October 19, 2017; Japan. https://www.pmda.go.jp/files/000220943.pdf#search=%27PMDA++RTRT%27. Accessed 29 Jan 2020.

Funding

The author(s) received no financial support for the research, authorship, and/or publication of this article.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kajiwara, E., Kamizato, H. & Shikano, M. Impact of Quality by Design Development on the Review Period of New Drug Approval and Product Quality in Japan. Ther Innov Regul Sci 54, 1192–1198 (2020). https://doi.org/10.1007/s43441-020-00146-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43441-020-00146-y