Abstract

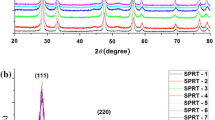

This research reports the synthesis, characterization, and electrical properties of the systems EryCe1−yO2−δ (y = 0.05, 0.1, and 0.15), and the effect of the incorporation of sintering aids (2 wt.% of CaO, MgO, and TiO2) on the electrical properties of the composition Er0.1Ce0.9O1.95, to be used as ceramic solid electrolytes in low-temperature solid oxide fuel cells (LT-SOFC). All EryCe1−yO2−δ samples were obtained by mechanochemistry (20 h of milling) and characterized by XRD. The morphology of the pure sintered compositions and with the incorporation of sintering aids (sintered at 1200 °C) was evaluated by FE-SEM. Electrical properties as a function of temperature (200–650 °C) and frequency (100 Hz–1 MHz) were evaluated by impedance spectroscopy. It reveals an increase of bulk ionic conductivity for higher contents of Er, as the number of oxygen vacancies increases. The higher value of conductivity (6.7 × 10–3 S cm−1) at 650 °C was for the composition Er0.15Ce0.85O1.925, while the ionic conductivity of Er0.1Ce0.9O1.95 at 650 °C increased from 2.68 × 10–3 S cm−1 to a maximum of 1.54 × 10–2 S cm−1 with the incorporation of CaO as additive. These improvements in bulk ionic conductivities can contribute to the development of more efficient electrolytes for the LT-SOFC technology.

Similar content being viewed by others

Data availability

All data generated during this research are available from the corresponding author on reasonable request.

References

S.Z. Golkhatmi, M.I. Asghar, Renew. Sustain. Energy Rev. (2022). https://doi.org/10.1016/j.rser.2022.112339

E.D. Wachsman, K.T. Lee, Science (2011). https://doi.org/10.1126/science.1204090

B. Singh, S. Ghosh, S. Aich, B. Roy, J. Power Sources (2017). https://doi.org/10.1016/j.jpowsour.2016.11.019.J.B

N. Mahato, A. Banerjee, A. Gupta, S. Omar, K. Balani, Prog. Mater. Sci. (2015). https://doi.org/10.1016/j.pmatsci.2015.01.001

J.A. Labrincha, J.R. Frade, F.M.B. Marques, J. Mater. Sci. (1993). https://doi.org/10.1007/BF00353183

A. Mitterdorfer, L.J. Gauckler, MRS Proc. (1996). https://doi.org/10.1557/PROC-453-525

N. Jaiswal, K. Tanwar, R. Suman, D. Kumar, S. Upadhyay, O. Parkash, J. Alloy Compd. (2019). https://doi.org/10.1016/j.jallcom.2018.12.015

J.M. Ralph, C. Rossignol, R. Kumar, J. Electrochem. Soc. (2003). https://doi.org/10.1149/1.1617300

L. Zhang, J. Shan, Q. Wang, J. Alloy Compd. (2019). https://doi.org/10.1016/j.jallcom.2018.08.232

S. Ahmed, W.W. Kazmi, A. Hussain, M.Z. Khan, S. Bibi, M. Saleem, R.H. Song, Z. Sajid, A. Ullah, M.K. Khan, J. Korean Ceram. Soc. (2022). https://doi.org/10.1007/s43207-022-00261-6

V. Dusastre, J.A. Kilner, Solid State Ionics (1999). https://doi.org/10.1016/S0167-2738(99)00108-3

E.Y. Pikalova, V.I. Maragou, A.K. Demin, A.A. Murashkina, P.E. Tsiakaras, Solid State Ionics (2008). https://doi.org/10.1016/j.ssi.2007.12.086

M. Mogensen, N.M. Sammes, J.A. Tompsett, Solid State Ionics (2000). https://doi.org/10.1016/S0167-2738(99)00318-5

H. Yahiro, Y. Eguchi, K. Eguchi, H. Arai, J. Appl. Electrochem. (1998). https://doi.org/10.1007/BF01022246

K. Schwarz, Proc. Natl. Acad. Sci. U.S.A. (2006). https://doi.org/10.1073/pnas.0600327103

D.A. Andersson, S.I. Simak, N.V. Skorodumova, I.A. Abrikosov, B. Johansson, Proc. Natl. Acad. Sci. U.S.A. (2006). https://doi.org/10.1073/pnas.0509537103

H. Yahiro, K. Eguchi, H. Arai, Solid State Ionics (1989). https://doi.org/10.1016/0167-2738(89)90061-1

D.E. Puente-Martínez, J.A. Díaz-Guillén, S.M. Montemayor, J.C. Díaz-Guillén, O. Burciaga-Díaz, M.E. Bazaldúa-Medellín, M.R. Diaz-Guillen, A.F. Fuentes, Int. J. Hydrog. Energy (2020). https://doi.org/10.1016/j.ijhydene.2019.11.032

M. Kahlaoui, S. Chefi, A. Inoubli, A. Madani, C. Chefi, Ceram Int. (2013). https://doi.org/10.1016/J.CERAMINT.2012.10.230

A. Arabacı, M.F. Öksüzömer, Ceram Int. (2012). https://doi.org/10.1016/j.ceramint.2012.05.030

N. Cioatera, V. Parvulescu, A. Rolle, R.N. Vannier, Ceram. Int. (2012). https://doi.org/10.1016/J.CERAMINT.2012.03.058

A. Gondolini, E. Mercadelli, A. Sanson, S. Albonetti, L. Doubova, S. Boldrini, Ceram. Int. (2011). https://doi.org/10.1016/j.ceramint.2011.01.010

K. Venkataramana, C. Madhuri, C. Madhusudan, A. Bhogi, B. Srinivas, C.V. Reddy, Mater. Sci. Semicond. Process. (2022). https://doi.org/10.1016/j.mssp.2022.106495

F. Tietz, Solid Oxide Fuel Cells Encycl. Mater. Sci. Technol. (2008). https://doi.org/10.1016/B978-008043152-9.02210-7

K.C. Anjaneya, M.P. Singh, J. Alloy Compd. (2017). https://doi.org/10.1016/j.jallcom.2016.10.175

N. Momin, J. Manjanna, L. D’Souza, S.T. Aruna, S.S. Kumar, J. Alloy Compd. (2022). https://doi.org/10.1016/j.jallcom.2021.163012

G.B. Jung, T.J. Huang, M.H. Huang, C.L. Chang, J. Mater. Sci. (2001). https://doi.org/10.1023/A:1012964307388

E.Y. Pikalova, A.A. Murashkina, V.I. Maragou, A.K. Demin, V.N. Strekalovsky, P.E. Tsiakaras, Int. J. Hydrog. Energy (2011). https://doi.org/10.1016/j.ijhydene.2011.01.132

K. Yan, Q. Zhen, X. Song, Rare Met. (2007). https://doi.org/10.1016/S1001-0521(07)60221-6

S. Zha, C. Xia, G. Meng, J. Power Sources (2003). https://doi.org/10.1016/S0378-7753(02)00625-0

M.F. Han, Z.B. Yang, Z. Liu, H.R. Le, Key Eng. Mater. (2010). https://doi.org/10.4028/www.scientific.net/kem.434-435.705

G. Dell’Agli, L. Spiridigliozzi, M. Pansini, G. Accardo, S.P. Yoon, D. Frattini, Ceram. Int. (2018). https://doi.org/10.1016/j.ceramint.2018.06.269

M. Stojmenović, S. Bošković, M. Žunić, B. Babić, B. Matović, D. Bajuk-Bogdanović, S. Mentus, Mater. Chem. Phys. (2015). https://doi.org/10.1016/j.matchemphys.2015.01.036

M. Anwar, M. Ali, A. Muchtar, M.R. Somalu, Ceram. Int. (2019). https://doi.org/10.1016/j.ceramint.2018.12.023

C.E. Jeyanthi, R. Siddheswaran, R. Medlín, M.K. Chinnu, R. Jayavel, K. Rajarajan, J. Alloy Compd. (2014). https://doi.org/10.1016/j.jallcom.2014.05.208

S. Kuharuangrong, J. Power Sources (2007). https://doi.org/10.1016/j.jpowsour.2007.05.104

H. Wang, R. Du, H. Zhai, G. Xi, F. Wu, Ceram. Int. (2020). https://doi.org/10.1016/j.ceramint.2019.09.256

A.F. Fuentes, L. Takacs, J. Mater. Sci. (2013). https://doi.org/10.1007/s10853-012-6909-x

I. Shajahan, H.P. Dasari, M.B. Saidutta, Int. J. Hydrog. Energy (2020). https://doi.org/10.1016/j.ijhydene.2020.06.163

Y.C. Zhou, M.N. Rahaman, J. Mater. Res. (1993). https://doi.org/10.1557/JMR.1993.1680

R.D. Shannon, Acta Crystallogr. (1976). https://doi.org/10.1107/S0567739476001551

J.D. Nicholas, C. Lutgard, D. Jonghe, Solid State Ionics (2007). https://doi.org/10.1016/j.ssi.2007.05.019

L.A. Villas-Boas, F.M.L. Figueiredo, D.P.F. De Souza, F.M.B. Marques, Solid State Ionics (2014). https://doi.org/10.1016/j.ssi.2013.11.002

A.K. Jonscher, Dielectric Relaxation in Solids (Chelsea Dielectric, London, 1983)

G.F. Harrington, L. Sun, B. Yildiz, K. Sasaki, N.H. Perry, H.L. Tuller, Acta Mater. (2019). https://doi.org/10.1016/j.actamat.2018.12.058

H. Ozlu Torun, S. Cakar, J. Therm. Anal. Calorim. (2018). https://doi.org/10.1007/s10973-018-7189-8

M. Filal, C. Petot, M. Mokchah, C. Chateau, J.L. Carpentier, Solid State Ionics (1995). https://doi.org/10.1016/0167-2738(95)00137-U

D.W. Strickler, W.G. Carlson, J. Am. Ceram. Soc. (1964). https://doi.org/10.1111/j.1151-2916.1964.tb14368.x

F.M.L. Figueiredo, F.M.B. Marques, Wires Energy Environ. (2013). https://doi.org/10.1002/wene.23

Y.L. Kuo, Y.M. Su, Micro Nano Lett. (2012). https://doi.org/10.1049/mnl.2012.0178

Z. Tianshu, P. Hing, H. Huang, J. Kilner, J. Mater. Sci. (2002). https://doi.org/10.1023/A:1014362000128

W. Zając, L. Suescun, K. Świerczek, J. Molenda, J. Power Sources (2009). https://doi.org/10.1016/j.jpowsour.2008.12.020

P.S. Cho, S.B. Lee, D.S. Kim, J.H. Lee, D.Y. Kim, H.M. Park, ECS Solid State Lett. (2006). https://doi.org/10.1149/1.2214235

D. Pérez-Coll, P. Núñez, J.C.C. Abrantes, D.P. Fagg, V.V. Kharton, J.R. Frade, Solid State Ionics (2005). https://doi.org/10.1016/j.ssi.2005.06.023

P.C. Cajas-Daza, J.L. Almeida-Ferreira, J.A. Araujo, J.A. Euzébio-Paiva, R.A. Muñoz-Meneses, C.R. Moreira da Silva, Bol. Soc. Esp. Ceram. Vidrio (2022). https://doi.org/10.1016/j.bsecv.2021.04.003

S. Ramesh, M. Naganathappa, J. Vemula, Bol. Soc. Esp. Ceram. (2022). https://doi.org/10.1016/j.bsecv.2021.03.001

L. Mathur, Y. Namgung, H. Kim, S.J. Song, J. Korean Ceram. Soc. (2023). https://doi.org/10.1007/s43207-023-00296-3

Acknowledgements

This work was financially supported by Tecnológico Nacional de México (grants 14228.22-P and 17564). D. E. Puente-Martínez and K. A. Gonzalez-García thank Mexican CONACYT for the scholarship (557621 and 860984 respectively) granted for their Ph. D. studies. K. P. Padmasree thanks CONACYT Mexico for the grant A1-S-29845.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest.

Ethical approval

This paper meets the ethical standards of this journal.

Consent to participate

All authors agree with the review of this paper in this journal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Puente-Martínez, D.E., Díaz-Guillén, J.A., González-García, K.A. et al. Improving the electrical properties of Er-doped CeO2: effect of sintering aids CaO, MgO, and TiO2 on conductivity. J. Korean Ceram. Soc. 60, 817–829 (2023). https://doi.org/10.1007/s43207-023-00306-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43207-023-00306-4