Abstract

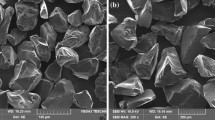

The main aim of this research was to investigate the mechanical behavior of aluminum (LM25) alloy hybrid metal matrix composites for high-temperature applications. The L25 alloy is hybrid reinforced with varying silicon carbide (SiC), niobium carbide (NbC), and magnesium oxide (MgO) nanoparticle compositions. Hybrid particle-reinforced composites are manufactured by means of a liquid manufacturing technique. The hot tensile behavior of the LM25 matrix and hybrid composites was examined under the temperature condition 30 °C–400 °C as per ASTM B557 and ASTM E8M standards using a hot tensile test rig. In addition, the surface morphology of the LM25 alloy and SiC-, NbC-, and MgO-reinforced composites was investigated using scanning electron microscopy/energy-dispersive X-ray spectroscopy (SEM/EDX). The results of the surface morphology investigation of the composites revealed that the SiC, NbC, and MgO particles were homogenously scattered within the matrix and revealed clearer interface bonding. In tensile test, the LM25 alloy/ 3wt% SiC, NbC, and MgO (LMSMN-3) composite showed a yield and tensile strength around 230.82 MPa and 251.71 MPa, which was 25% larger than the LM25 alloy materials, whereas LM25 alloy/1wt% SiC, NbC, and MgO (LMSMN-1) and LM25 alloy/2wt% SiC, NbC, and MgO (LMSMN-2) composites showed a yield and tensile strength of 176.45 MPa, 203.71 MPa,192 MPa, and 211.32 MPa, respectively, which was 23% and 16.75% higher than the LM25 alloy under room temperature condition. Also, at elevated temperatures such as 200℃ and 400℃, the LMSMN-3 composite exhibited a maximum increase in the tensile properties, i.e., 48.28% at 200℃ and of 61.12% at 400℃.

Similar content being viewed by others

References

T. Jayakumar, K. Annamalai, Investigation of hot tensile behavior of silicon carbide and magnesium oxide reinforced aluminum matrix composites. SILICON 11, 935–945 (2018). https://doi.org/10.1007/s12633-018-9965-2

H. Abdizadeh, R. Ebrahimifard, M.A. Baghchesara, Investigation of microstructure and mechanical properties of nano MgO reinforced Al composites manufactured by stir casting and powder metallurgy methods: a comparative study. Compos. B 56, 217–221 (2014). https://doi.org/10.1016/j.compositesb.2013.08.023

N. Haghdadi, A.B. Phillion, D.M. Maijer, Microstructure characterization and thermal analysis of aluminum alloy B2O6 during solidification. Metall. Mater. Trans. A. 46, 2073–2081 (2015). https://doi.org/10.1007/s11661-015-2780-0

B. Zhao, D. Gao, J. Shen, Z. Zhao, H. Guan, G. Liu, Y. Guan, Experiment and Numerical Analysis of Temperature Field of Cylinder Head Based on a GW4D20 Diesel Engine. In: SAE-China and FISITA (eds) Proceedings of the FISITA 2012 World Automotive Congress, Lecture Notes in Electrical Engineering 190. Springer, Cham, pp 965–976 (2013)

C.G. Chen, J. Luo, Z.M. Guo, W.W. Yang, J. Chen, Microstructural evolution and mechanical properties of in situ TiB2/Al composites under high-intensity ultrasound. Rare Met. 34, 168–172 (2015). https://doi.org/10.1007/s12598-014-0442-9

M. Karbalaei Akbari, H.R. Baharvandi, K. Shirvanimoghaddam, Tensile and fracture behavior of nano/micro TiB2 particle reinforced casting A356 aluminum alloy composites. Mater. Des. 66, 150–161 (2015). https://doi.org/10.1016/j.matdes.2014.10.048

J. Oñoro, M.D. Salvador, L.E.G. Cambronero, High-temperature mechanical properties of aluminium alloys reinforced with boron carbide particles. Mater. Sci. Eng. A 499, 421–426 (2009). https://doi.org/10.1016/j.msea.2008.09.013

B. Vijaya Ramnath, C. Elanchezhian, M. Jaivignesh, S. Rajesh, C. Parswajinan, A. Siddique Ahmed Ghias, Evaluation of mechanical properties of aluminium alloy–alumina–boron carbide metal matrix composites. Mater. Des. 58, 332–338 (2014). https://doi.org/10.1016/j.matdes.2014.01.068

C. Sun, M. Song, Z. Wang, Y. He, Effect of particle size on the microstructures and mechanical properties of SiC-reinforced pure aluminum composites. J. Mater. Eng. Perform. 20, 1606–1612 (2011). https://doi.org/10.1007/s11665-010-9801-3

S.Y. Wang, Q. Tang, D.J. Li, J.X. Zou, X.Q. Zeng, Q.B. Ouyang, W.J. Ding, The hot workability of SiCp/2024 Al composite by stir casting. Mater. Manuf. Processes 30, 624–630 (2015). https://doi.org/10.1080/10426914.2014.952027

N. Altinkök, Optimization of mechanical properties of hybrid Al2O3/SiCp reinforced composites produced by pressure-assisted aluminum infiltration. Jom 66, 909–919 (2014). https://doi.org/10.1007/s11837-013-0779-9

C. Sun, R. Shen, M. Song, Y. Du, Mechanical behaviors of sic particle reinforced al matrix composites: a study based on finite element method. Adv. Mat. Res. 535–537, 3–7 (2012). https://doi.org/10.4028/www.scientific.net/AMR.535-537.3

T. Rajmohan, K. Palanikumar, S. Ranganathan, Evaluation of mechanical and wear properties of hybrid aluminium matrix composites. Trans. Nonferrous Met. Soc. China (Engl. Ed.) 23, 2509–2517 (2013). https://doi.org/10.1016/S1003-6326(13)62762-4

A.A. Yar, M. Montazerian, H. Abdizadeh, H.R. Baharvandi, Microstructure and mechanical properties of aluminum alloy matrix composite reinforced with nano-particle MgO. J. Alloys Compd. 484, 400–404 (2009). https://doi.org/10.1016/j.jallcom.2009.04.117

K. Ravikumar, K. Kiran, V.S. Sreebalaji, Characterization of mechanical properties of aluminium/tungsten carbide composites. Measurement (Lond) 102, 142–149 (2017). https://doi.org/10.1016/j.measurement.2017.01.045

M.J. Styles, C.R. Hutchinson, Y. Chen, A. Deschamps, T.J. Bastow, The coexistence of two S (Al2CuMg) phases in Al–Cu–Mg alloys. Acta Mater 60, 6940–6951 (2012). https://doi.org/10.1016/j.actamat.2012.08.044

R. Hambleton, H. Jones, W.M. Rainforth, Effect of alloy composition and reinforcement with silicon carbide on the microstructure and mechanical properties of three silicide dispersion strengthened aluminium alloys. Mater. Sci. Eng. A 304–306, 524–528 (2001). https://doi.org/10.1016/S0921-5093(00)01508-2

Y. Yang, K. Yu, Y. Li, D. Zhao, X. Liu, Evolution of nickel-rich phases in Al–Si–Cu–Ni–Mg piston alloys with different Cu additions. Mater. Des. 33, 220–225 (2012). https://doi.org/10.1016/j.matdes.2011.06.058

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jayakumar, T., Annamalai, K. Hot tensile behavior of SiC-, NbC-, and MgO-reinforced LM25 metal matrix composites for high-temperature applications. J. Korean Ceram. Soc. 60, 364–372 (2023). https://doi.org/10.1007/s43207-022-00271-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43207-022-00271-4